Trevanion

Greatest Of All Time

LBCarpentry":28jy6rmb said:My very first thought was........why are your horns all different lengths, and why are your tenons that long?

It is unwise to question the methods of a master!

LBCarpentry":28jy6rmb said:My very first thought was........why are your horns all different lengths, and why are your tenons that long?

When I order timber for stiles I usually order them 100mm longer for horns (50mm each end) If i get a little planer snipe or want to use the end for setting up the tenoner I've got a bit spare. If the timber supplier sends the pieces longer it's not worth cutting off 100-200mm and putting away in the rack, it just goes in the log bin after I've cut the horns off on the table saw. The only thing I try and do after the glue up is make sure at least one end of the door horns are of similar length.LBCarpentry":ncdgco81 said:My very first thought was........why are your horns all different lengths, and why are your tenons that long?

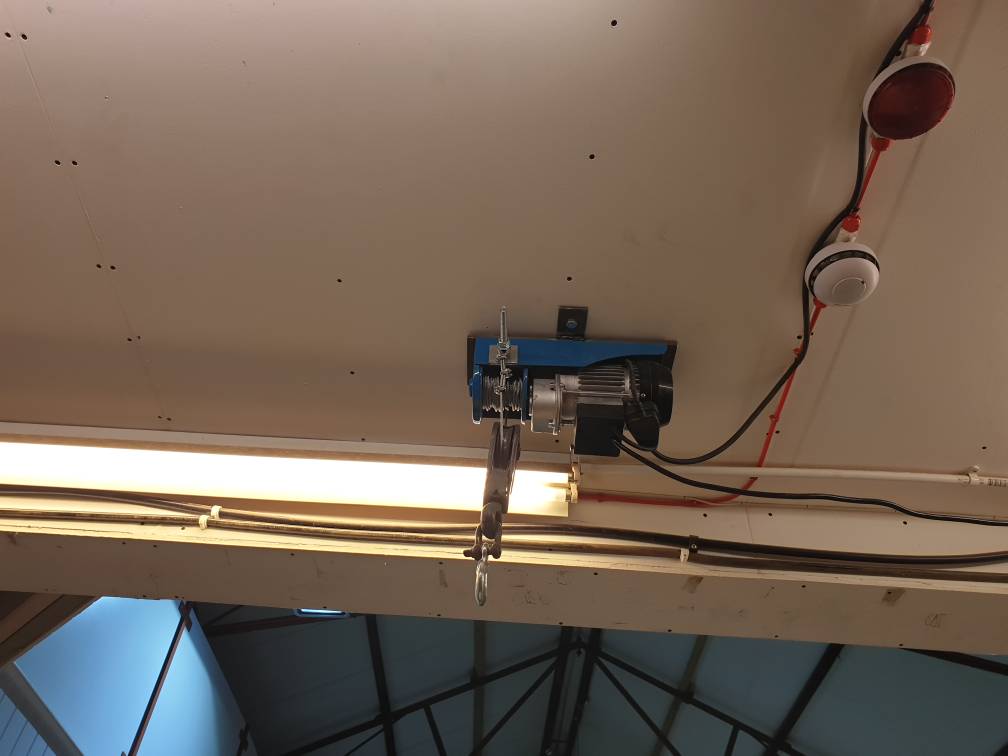

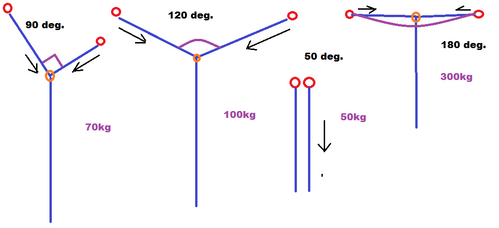

I think it's best I put this down as a practice run to prove it works then have a proper go.Inspector":3b49gnd9 said:There are very soft flexible flat straps about an inch wide that can lift a ton. They come with a loop at each end and as a continuous loop too. Although the seam where they are lapped and sewn together is stiffer. For the loads you're picking up you can make a spreader bar out of nothing more than a spruce 2x4 with a couple notches in the ends. I would remove your winch mounting screws and put up a 2x10 flat to the ceiling spanning three joists above with 3 or 4 long screws in each. Then you can have a couple carriage bolts come through to bolt the winch back on to.

Pete

ColeyS1":2jh9wpxr said:When I order timber for stiles I usually order them 100mm longer for horns (50mm each end) If i get a little planer snipe or want to use the end for setting up the tenoner I've got a bit spare. If the timber supplier sends the pieces longer it's not worth cutting off 100-200mm and putting away in the rack, it just goes in the log bin after I've cut the horns off on the table saw. The only thing I try and do after the glue up is make sure at least one end of the door horns are of similar length.LBCarpentry":2jh9wpxr said:My very first thought was........why are your horns all different lengths, and why are your tenons that long?

It stands nicer then if I need to use my bench for other things.

The tenons I usually keep longer for wedging.

I usually allow 2-3mm slop on the sides of the tenons (outer edge) and then drive the wedges home. I found having the tenon protrude 10 or so mm gives the wedge a little extra support when I start tapping them in. I use to get more wedges snap/buckle when I had the tenons shorter, the cut off saw on the tenoner makes it easy enough to do. I always think having a wedged tenon is like leaving the sash clamps on.

It's not necessarily the right way to do it, it's just a way I've found that works for me. My old foreman use to say 'never be afraid to ask questions' listen to what everyone has to say, weigh up the pros and cons and decide yourself what works best for you [WINKING FACE]

Sent from my SM-G960F using Tapatalk

LBCarpentry":35jb0879 said:This is very interesting. When I prepare the stiles for wedges, I mark a line 8mm either side of the mortise and use a chisel to chamfer down into the mortise. This creates a wedge shape which in turn, means I can drive the wedge in deeper. This was how I’ve always been taught. I’m interested in your method though as it sounds quicker.......

you said 2-3mm slop... are you over cutting the mortises 2mm or under cutting the tenons 2mm? And your not creating any wedge shape, your just driving the wedges in?

Woody2Shoes":usxl6rha said:I have one of those electric hoists and I find it very useful, I mounted it on a short length of scaffolding tube - which allows me to position it at different positions along the tube (which is otherwise fixed at both ends).

Cheers, W2S

The mortices are 2-3....realistically 4mm wider on the outer edge. I usually set the haunch depth on the morticer then use the same depth setting for my wedges- a bit like you though, that's how I was taught. Do you need to chop the slope accurately to match your wedge then ?LBCarpentry":zuq2jb85 said:ColeyS1":zuq2jb85 said:When I order timber for stiles I usually order them 100mm longer for horns (50mm each end) If i get a little planer snipe or want to use the end for setting up the tenoner I've got a bit spare. If the timber supplier sends the pieces longer it's not worth cutting off 100-200mm and putting away in the rack, it just goes in the log bin after I've cut the horns off on the table saw. The only thing I try and do after the glue up is make sure at least one end of the door horns are of similar length.LBCarpentry":zuq2jb85 said:My very first thought was........why are your horns all different lengths, and why are your tenons that long?

It stands nicer then if I need to use my bench for other things.

The tenons I usually keep longer for wedging.

I usually allow 2-3mm slop on the sides of the tenons (outer edge) and then drive the wedges home. I found having the tenon protrude 10 or so mm gives the wedge a little extra support when I start tapping them in. I use to get more wedges snap/buckle when I had the tenons shorter, the cut off saw on the tenoner makes it easy enough to do. I always think having a wedged tenon is like leaving the sash clamps on.

It's not necessarily the right way to do it, it's just a way I've found that works for me. My old foreman use to say 'never be afraid to ask questions' listen to what everyone has to say, weigh up the pros and cons and decide yourself what works best for you [WINKING FACE]

Sent from my SM-G960F using Tapatalk

This is very interesting. When I prepare the stiles for wedges, I mark a line 8mm either side of the mortise and use a chisel to chamfer down into the mortise. This creates a wedge shape which in turn, means I can drive the wedge in deeper. This was how I’ve always been taught. I’m interested in your method though as it sounds quicker.......

you said 2-3mm slop... are you over cutting the mortises 2mm or under cutting the tenons 2mm? And your not creating any wedge shape, your just driving the wedges in?

Spot on,sapele. It's in aluminium primer now awaiting the next few licks of paint.pollys13":nxnmwpjt said:What timber is that in the door Coley? The ribboning I thought might be Sapele, the rest???

Woody2Shoes":1kcsloh4 said:I have one of those electric hoists and I find it very useful, I mounted it on a short length of scaffolding tube - which allows me to position it at different positions along the tube (which is otherwise fixed at both ends).

I also got a couple of straps like those below - they can grip very tightly with minimal risk of marking esp. with a bit of old carpet strategically positioned as mentioned above. +1 for the carabiners also.

I got my straps from Screwfix with the winch, but their search facility is such pants I can't find any on their website now!

https://www.machinemart.co.uk/p/2-metre ... ing-strap/

https://www.machinemart.co.uk/c/lifting-straps--strops/

Cheers, W2S

Enter your email address to join: