So I'm looking at starting the legs and aprons for my Table tonight,

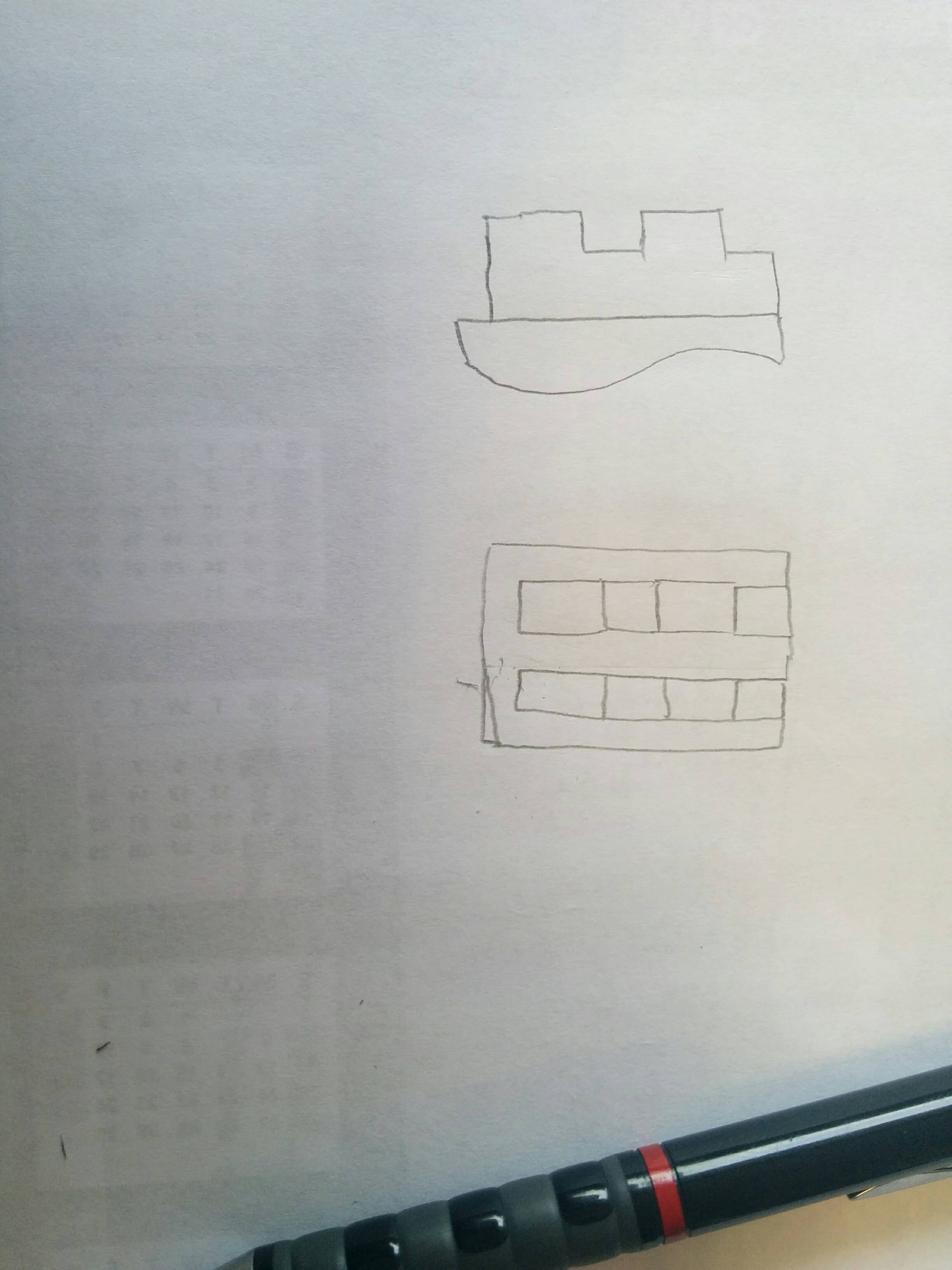

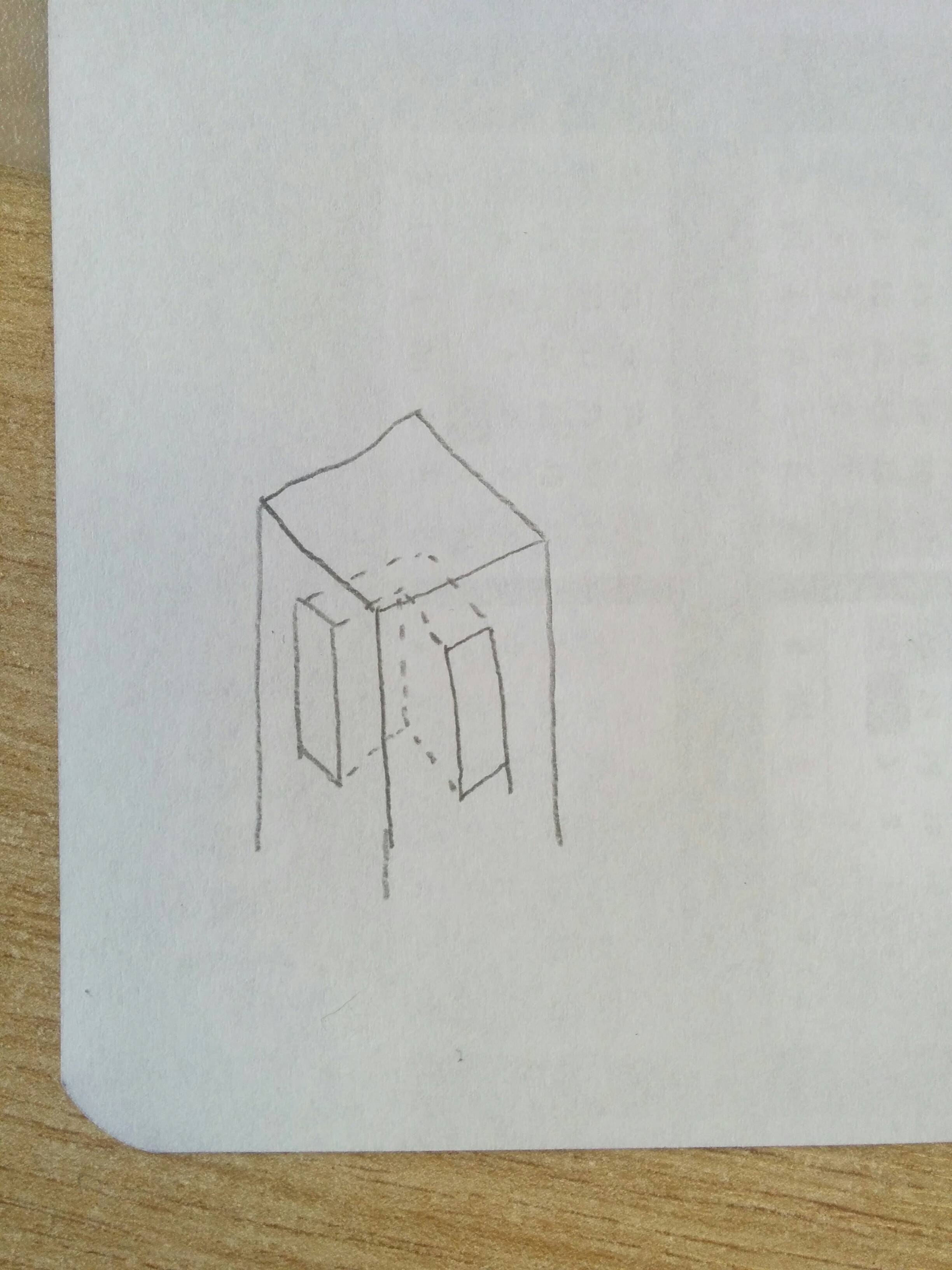

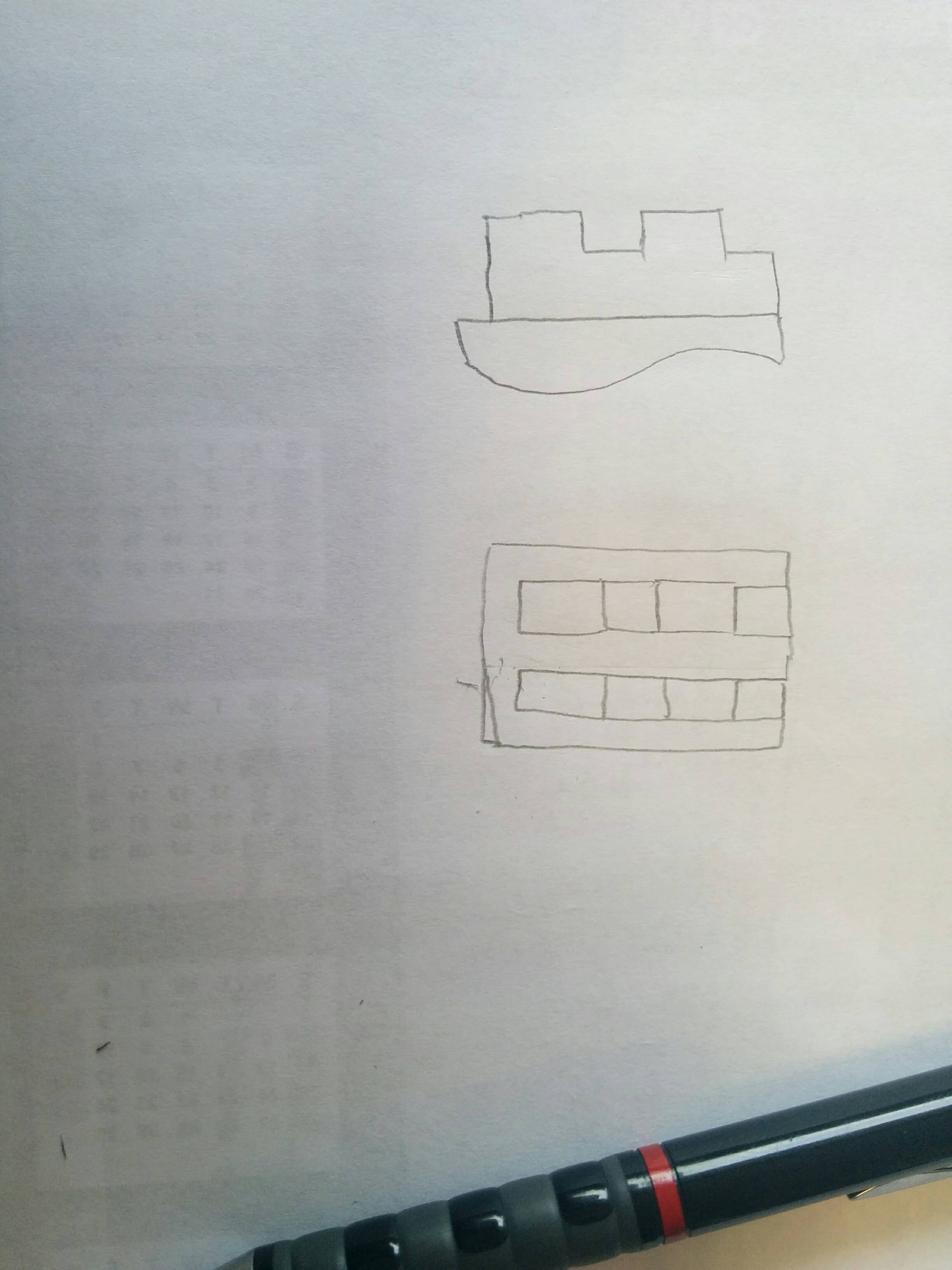

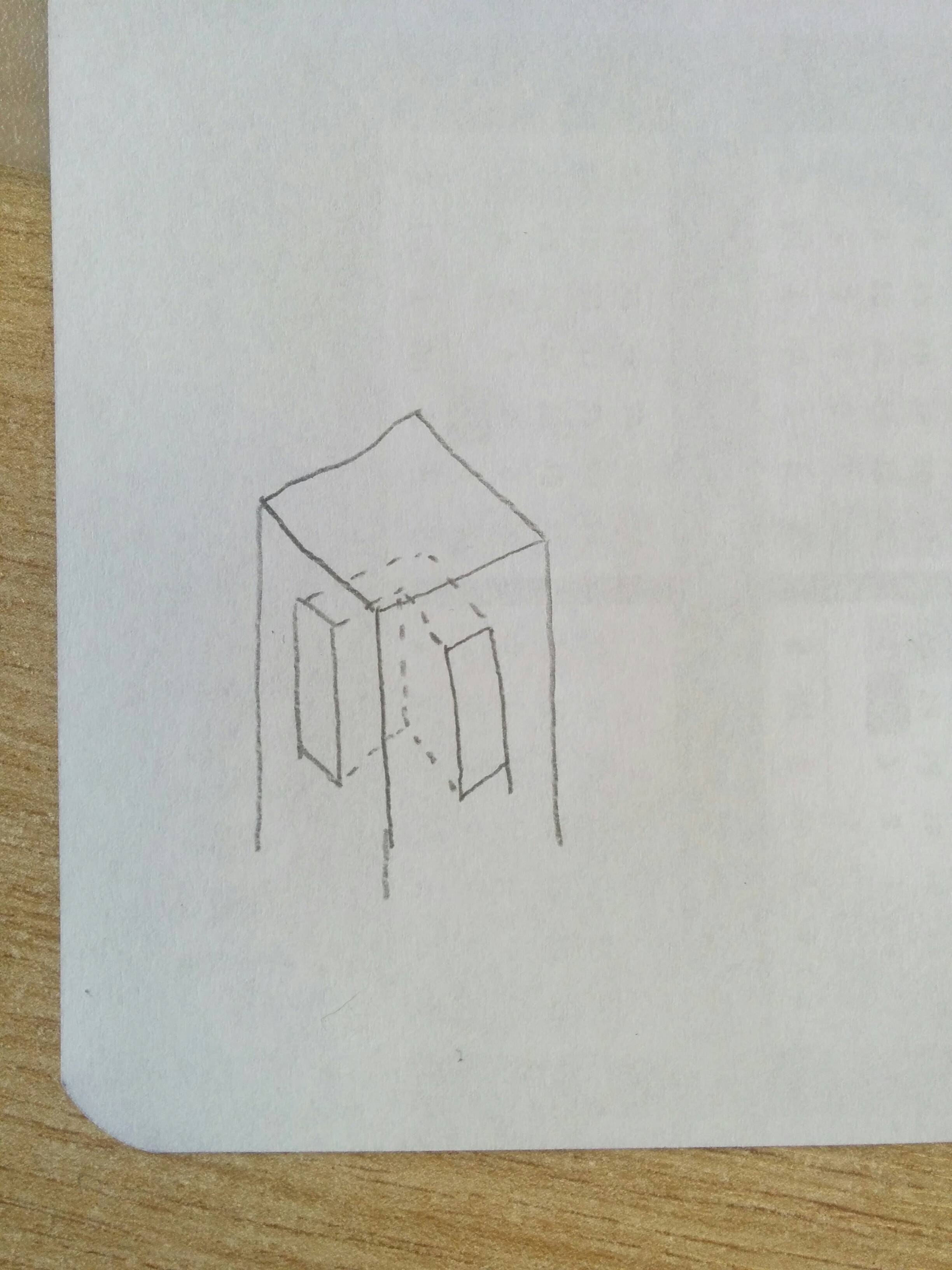

The stock I'm joining is 2" by 4", so I'm looking at using a double twin haunched tennon, to maximise glue surface, minimise racking, and prevent breakout of the mortice.

Previously I've done tables with an L-Shaped mortice and mitred the tenons to join in the middle, but this is a very challenging proposition with 8 separate mortices to join up on each leg, and I'm thinking that it will be wholly unnecessary on top of all the other techniques applied, and stub tenons would be sufficient.

So... am I being silly and over engineering these joints, or would the approach of Apply all the Techniques! actually be worthwhile?

The stock I'm joining is 2" by 4", so I'm looking at using a double twin haunched tennon, to maximise glue surface, minimise racking, and prevent breakout of the mortice.

Previously I've done tables with an L-Shaped mortice and mitred the tenons to join in the middle, but this is a very challenging proposition with 8 separate mortices to join up on each leg, and I'm thinking that it will be wholly unnecessary on top of all the other techniques applied, and stub tenons would be sufficient.

So... am I being silly and over engineering these joints, or would the approach of Apply all the Techniques! actually be worthwhile?