custard

Established Member

It's been many years since a proper hard wax has been available commercially in the UK, so I was interested when Workshop Heaven announced a product called Alfie Shine,

https://www.workshopheaven.com/alfie-shine.html

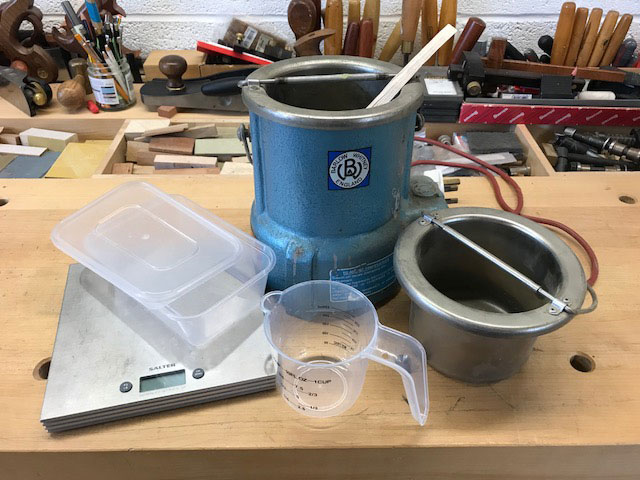

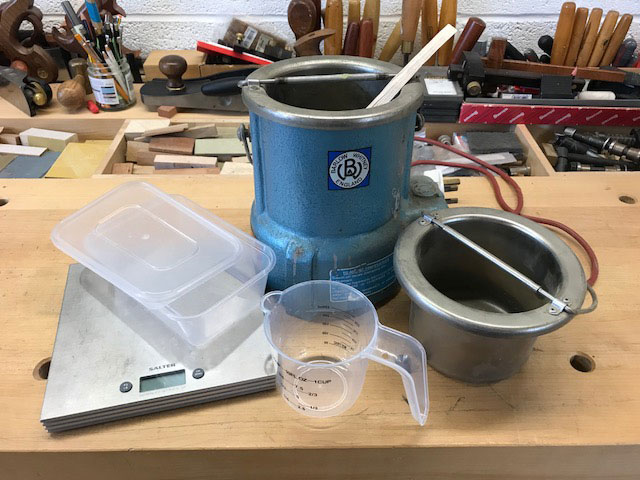

A couple of weeks ago someone called Mr Day sent me a sample of Alfie Shine, there was no covering note so I'm a bit stumped, but I'm grateful he did and it gives me a chance to run a little evaluation of paste wax (such Briwax or Black Bison) versus Alfie Shine versus the traditional hard wax that I brew myself. There's no magic in making a hard wax, it's just one part carnauba to four parts beeswax with an equal volume of turps. I blend it together in an electric glue pot but any sort of bain marie type arrangement will work fine,

There are some safety considerations, and endless tweaks you can make to the recipe. You can read more about all this here,

soft-beeswax-polish-recipe-t109073.html

Wax can be applied over many different finishes, but I decided to look at wax over sanding sealer.

A decade or two ago this was a very popular combination, used with hard wax it's a bit too glossy for modern tastes so it seems to have fallen out of favour amongst furniture makers, although I believe turners still use it. I guess it's worth saying a little more about sanding sealers as this is the base coat I'll be using. There are several different types, Cellulose, Shellac, and even a water based Acrylic sanding sealer (although I've never used this so I won't comment on it). Cellulose has the advantage of ultra quick drying, only about 5 or 10 minutes between coats, plus it can take a very wide range of different top coats. The down sides are it's a bit pongy in an enclosed space and I'm always slightly suspicious of cellulose over the very long term because of both yellowing and flaking.

Shellac sanding sealer is slower drying, 10-20 minutes, but has a slightly longer shelf life than cellulose (although neither last all that long). You may also come across something called "Spirit Sanding Sealer", this doesn't have a great reputation in the trade and no one I've spoken to is quite sure what's actually in it! There's a suspicion that the name is designed to gull the unwary into believing it's shellac based despite the cheap price, but it doesn't function well as a knotting and warns on the tin that only wax can be used on top of it, which suggests there really isn't much if any actual shellac inside!

The next question was what timber to test it all on? The sanding sealer/wax combination is quite good at grain filling, plus it tends not to darken pale timbers too much. So an obvious candidate would be Ash, a timber which is normally quite problematic to finish. I found some boards of nicely rippled Ash with an Olive Ash streak, which would add some further elements into the test. So I took an offcut from these and set to.

I sanded the board down through the grits, 80/120/180/220. And then gave two brushed coats of Morrells Shellac Sanding Sealer, which I knocked back with 320 grit on a hard sanding pad before blowing off the dust with an air line.

Actually I'm going to take a little break here, but I'll be back later to finish this off.

https://www.workshopheaven.com/alfie-shine.html

A couple of weeks ago someone called Mr Day sent me a sample of Alfie Shine, there was no covering note so I'm a bit stumped, but I'm grateful he did and it gives me a chance to run a little evaluation of paste wax (such Briwax or Black Bison) versus Alfie Shine versus the traditional hard wax that I brew myself. There's no magic in making a hard wax, it's just one part carnauba to four parts beeswax with an equal volume of turps. I blend it together in an electric glue pot but any sort of bain marie type arrangement will work fine,

There are some safety considerations, and endless tweaks you can make to the recipe. You can read more about all this here,

soft-beeswax-polish-recipe-t109073.html

Wax can be applied over many different finishes, but I decided to look at wax over sanding sealer.

A decade or two ago this was a very popular combination, used with hard wax it's a bit too glossy for modern tastes so it seems to have fallen out of favour amongst furniture makers, although I believe turners still use it. I guess it's worth saying a little more about sanding sealers as this is the base coat I'll be using. There are several different types, Cellulose, Shellac, and even a water based Acrylic sanding sealer (although I've never used this so I won't comment on it). Cellulose has the advantage of ultra quick drying, only about 5 or 10 minutes between coats, plus it can take a very wide range of different top coats. The down sides are it's a bit pongy in an enclosed space and I'm always slightly suspicious of cellulose over the very long term because of both yellowing and flaking.

Shellac sanding sealer is slower drying, 10-20 minutes, but has a slightly longer shelf life than cellulose (although neither last all that long). You may also come across something called "Spirit Sanding Sealer", this doesn't have a great reputation in the trade and no one I've spoken to is quite sure what's actually in it! There's a suspicion that the name is designed to gull the unwary into believing it's shellac based despite the cheap price, but it doesn't function well as a knotting and warns on the tin that only wax can be used on top of it, which suggests there really isn't much if any actual shellac inside!

The next question was what timber to test it all on? The sanding sealer/wax combination is quite good at grain filling, plus it tends not to darken pale timbers too much. So an obvious candidate would be Ash, a timber which is normally quite problematic to finish. I found some boards of nicely rippled Ash with an Olive Ash streak, which would add some further elements into the test. So I took an offcut from these and set to.

I sanded the board down through the grits, 80/120/180/220. And then gave two brushed coats of Morrells Shellac Sanding Sealer, which I knocked back with 320 grit on a hard sanding pad before blowing off the dust with an air line.

Actually I'm going to take a little break here, but I'll be back later to finish this off.