Trevanion

Greatest Of All Time

Got a minor electrical/motor problem, so I thought I’d ask the hive mind of higher knowledge

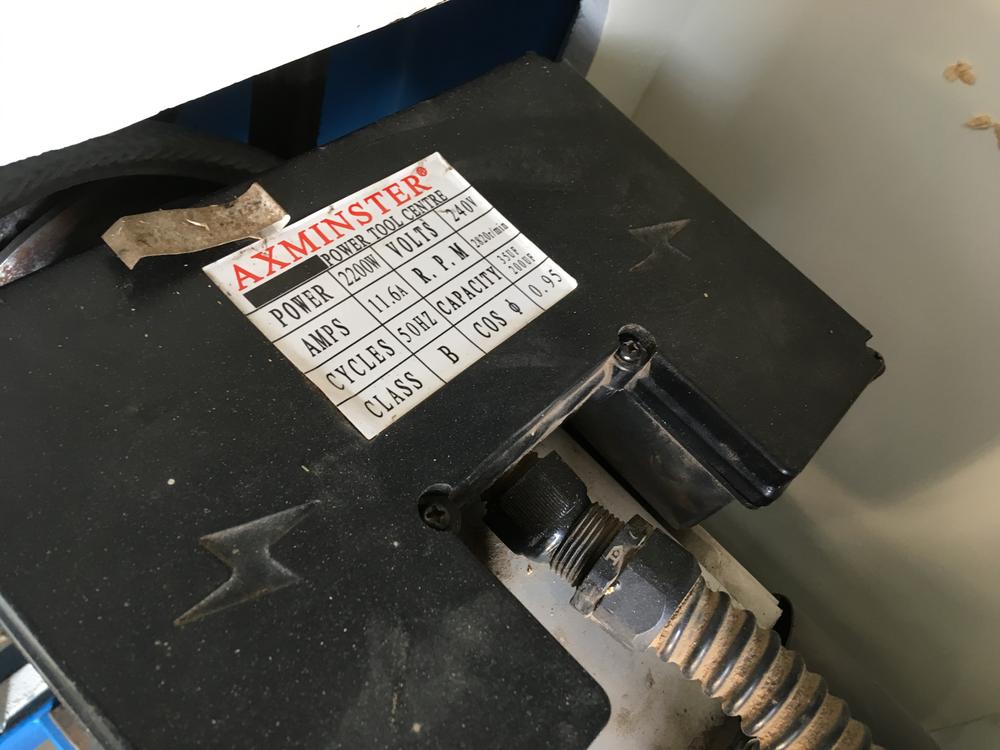

I’ve been fixing up this old machine which at some point had had a motor swap from a three phase motor to a single phase Axminster one with two capacitors on top. I’ve put a new starter switch on the machine and a more heavy duty flex on it (steel braided 5 core wire, joined wire 1&2 for live and 3&4 for neutral). The motor has 3 belts on it, 2 run the cutterblock and the third the power-feed, I tightened them up not super tight but what I felt was good enough/still able to turn the belt 90 degrees.

It started up beautifully about 4 times with no sign of strain on start up. And then it started not wanting to start properly with that classic “brrrt” noise, even with the belts slackened up it didn't want to start, giving the machine a bit of motivation by turning the flywheel helps but still there’s a lot of strain trying to get it up to speed. With the belts off and it does start but there seems to be a tiny bit of resistance in the first second or so. I don’t think supply is an issue as I’ve got it on a 32amp plug with adequate supply going in, and the overload on the starter is set right or the motor. Motor does seem to get a bit warm after trying to start it but I would think it would anyway if the fan wasn’t turning.

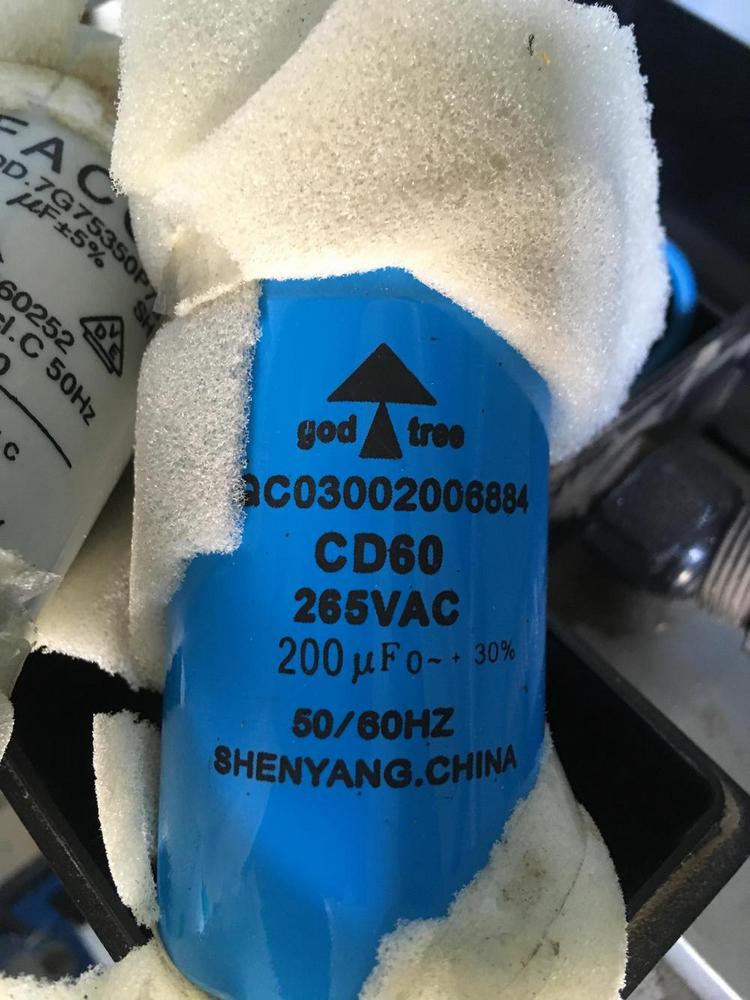

I’m thinking it could be the capacitors but I’m not 100% on that as usually the motor wouldn’t want to start at all with a dodgy capacitor, but I don’t have massive amounts of experience with this kind of thing anyway. One capacitor is 35 microfarad and the other is 200 microfarad from what I could tell off them. I could get new capacitors but I don’t want to spent the cash if it’s clearly something else.

Anyone got any ideas?

I’ve been fixing up this old machine which at some point had had a motor swap from a three phase motor to a single phase Axminster one with two capacitors on top. I’ve put a new starter switch on the machine and a more heavy duty flex on it (steel braided 5 core wire, joined wire 1&2 for live and 3&4 for neutral). The motor has 3 belts on it, 2 run the cutterblock and the third the power-feed, I tightened them up not super tight but what I felt was good enough/still able to turn the belt 90 degrees.

It started up beautifully about 4 times with no sign of strain on start up. And then it started not wanting to start properly with that classic “brrrt” noise, even with the belts slackened up it didn't want to start, giving the machine a bit of motivation by turning the flywheel helps but still there’s a lot of strain trying to get it up to speed. With the belts off and it does start but there seems to be a tiny bit of resistance in the first second or so. I don’t think supply is an issue as I’ve got it on a 32amp plug with adequate supply going in, and the overload on the starter is set right or the motor. Motor does seem to get a bit warm after trying to start it but I would think it would anyway if the fan wasn’t turning.

I’m thinking it could be the capacitors but I’m not 100% on that as usually the motor wouldn’t want to start at all with a dodgy capacitor, but I don’t have massive amounts of experience with this kind of thing anyway. One capacitor is 35 microfarad and the other is 200 microfarad from what I could tell off them. I could get new capacitors but I don’t want to spent the cash if it’s clearly something else.

Anyone got any ideas?