El Barto

👍

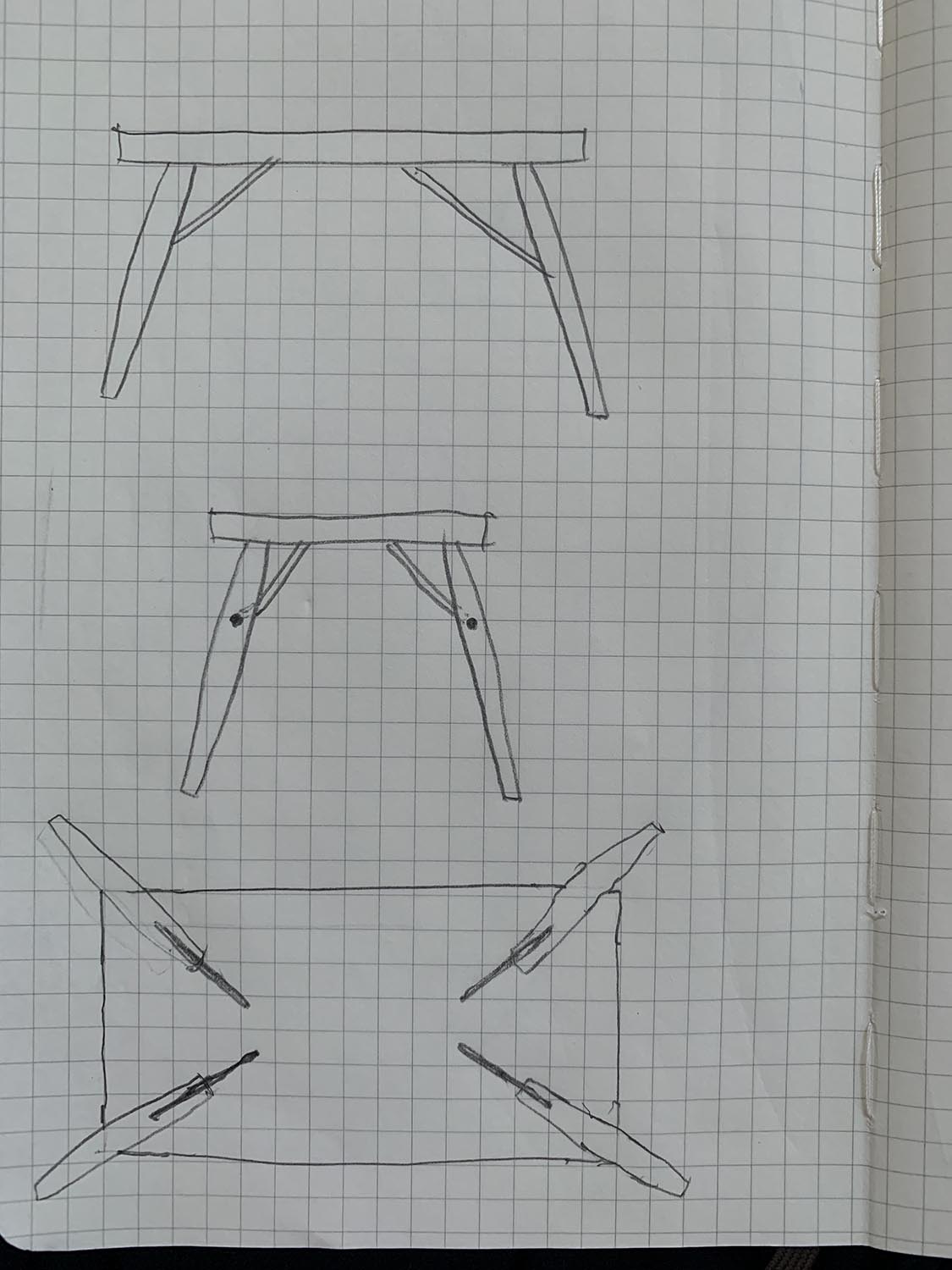

Has anyone done this? I want to use some brass or bronze rod for stretchers in a table; the rod would be inserted into the legs and also the table top - both oak.

i HAVE ONLY DONE THIS WITH PLAQUES AND HAD NO TROUBLE WITH USUAL 2 PART EPOXY

is the stretcher going to add much stability to the table. thinking of the table being bumped into from the side or end, I would have thought that 2 braces at right angles would have been stronger.

I expect that these stretchers will be in tension and therefore you're looking to maximise 'pull-out resistance' - on that basis, I'd try and cut a thread in the metal at each end (same idea as why steel rebar is not smooth but 'bobbly') and widen the bottom of each hole (so it's sort of conical) and try with epoxy.

I reckon you could achieve the same grip by drilling a hole though the bar, couldn't you? That might be easier for most people rather than trying to cut a thread.

Enter your email address to join: