Hello guys,

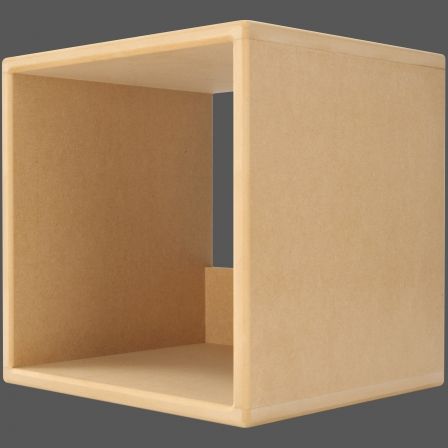

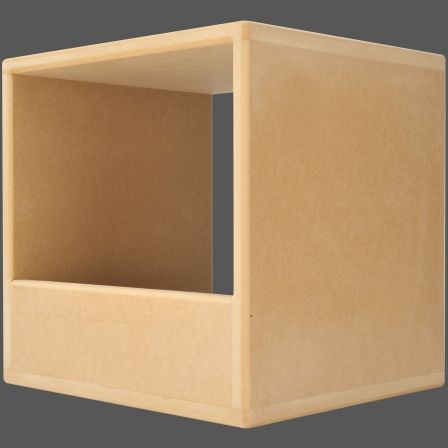

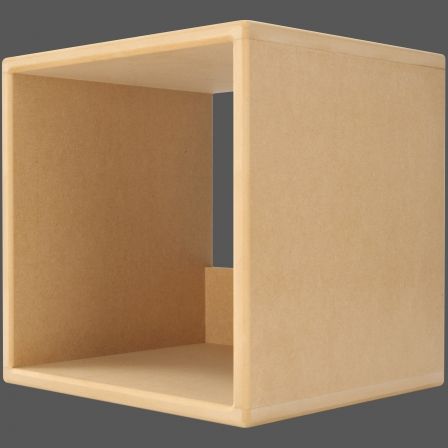

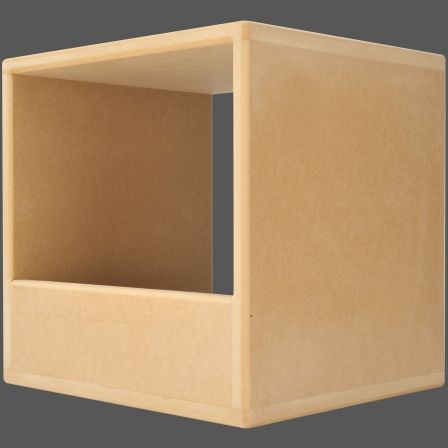

Want to knock up some MDF 12"x12"x12" module cubes for storing vinyl in.......akin to this:

And was wondering the best way to cut down the board without a table saw.

Was thinking clamping down a 2x1 as a fence and using a Jig saw......bad/dangerous practice?

Want to knock up some MDF 12"x12"x12" module cubes for storing vinyl in.......akin to this:

And was wondering the best way to cut down the board without a table saw.

Was thinking clamping down a 2x1 as a fence and using a Jig saw......bad/dangerous practice?