A

Anonymous

Guest

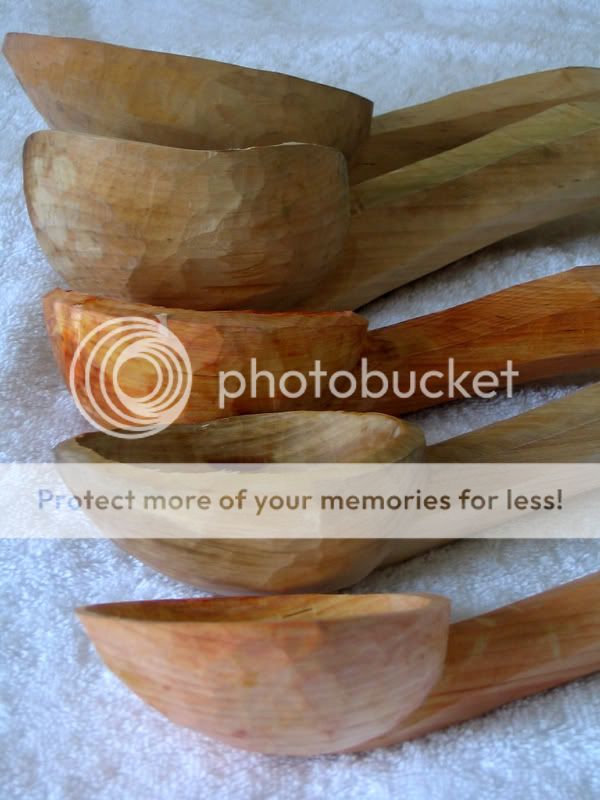

Here is a few pics of my 1 st attempt at handle carving this afternoon

the wood is burr elm.

I used a chisel, small rasp and normal files also. Its still roughed out stage, final claen up tomorrow

heres a few close up's

another london pattern blank

unfortunately the burr elm turnrd out to be a bit crumbly but it should turn out ok with care

the wood is burr elm.

I used a chisel, small rasp and normal files also. Its still roughed out stage, final claen up tomorrow

heres a few close up's

another london pattern blank

unfortunately the burr elm turnrd out to be a bit crumbly but it should turn out ok with care