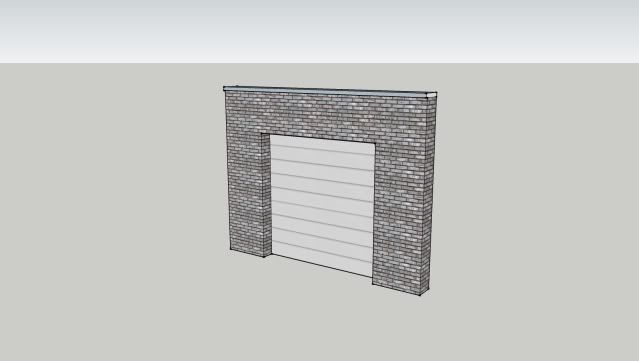

I've decided to block up the garage door of my 'shop.

It is a single garage door. I have access to the garage from inside the house. Although it is useful having the ability to lift the garage door to get materials and machinery ( ) in there, it has some serious downsides. Cold and noise pollution are the two major ones.

) in there, it has some serious downsides. Cold and noise pollution are the two major ones.

So, I want to leave the door in-situ (for external appearances), but will screw it to the wooden frame, meaning that the horizontal arms onto which it lifts can be removed. I then intend to insulate with some kingspan and fix some ply or MDF across the width of the garage.

Hopefully this also means that if machinery has to come out (or in!), then it should only be a 10 minute job to remove the internal "wall" and unscrew the garage door for open access.

Any comments/suggestions before I take the plunge?

Cheers

Karl

It is a single garage door. I have access to the garage from inside the house. Although it is useful having the ability to lift the garage door to get materials and machinery (

So, I want to leave the door in-situ (for external appearances), but will screw it to the wooden frame, meaning that the horizontal arms onto which it lifts can be removed. I then intend to insulate with some kingspan and fix some ply or MDF across the width of the garage.

Hopefully this also means that if machinery has to come out (or in!), then it should only be a 10 minute job to remove the internal "wall" and unscrew the garage door for open access.

Any comments/suggestions before I take the plunge?

Cheers

Karl