9fingers

Established Member

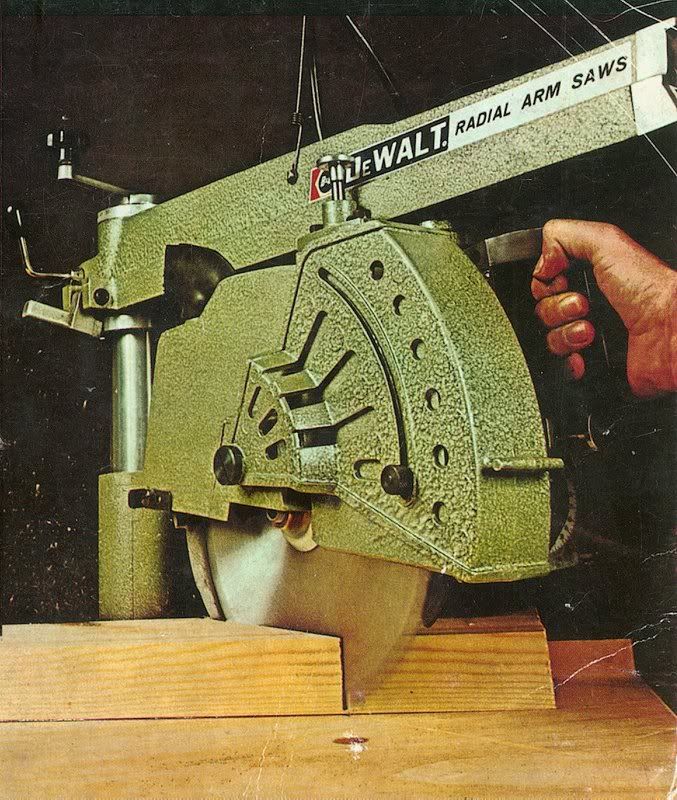

I have a Dewalt DW1753 RAS bought 2nd hand as a refurbishment project.

Not much progress to date apart from getting a manual from Dewalt CS as it is not one they keep on line.

Bob

Not much progress to date apart from getting a manual from Dewalt CS as it is not one they keep on line.

Bob