Farmer Giles

The biggest tool in the box

I have had an older Startrite 351E bandsaw from new, about 15 years I think, it works well but the fence is a bit agricultural. The fence works well enough at what it does, but it lacks finesse, it is not easy to fit tall fences for resawing, or stops etc. All can be done, but having no T-slots makes it difficult. Also minor adjustment is a little crude both in correction and for width.

So I took the plunge and bought the Kreg KMS7200 with microadjuster, total cost about £125.

Sorry about the imperial measurements, it's just easier sometimes when working with US kit.

I wasn't expecting it until next week however it arrived early so I just finished round one of tinkering with it. First impression was quality components.

I already knew I would have to drill the front of the table as the existing fence bolts underneath. So following the instructions, I offered up the rail to the front of the table so the top was 1/16" below the bottom of the mitre gauge slot. I lined up the existing holes in the rail so that the single right hand bolt slot and the one of the three left hand slots did not coincide with any under-table obstruction like a casting web and clamped it into position while I marked the table through the slots with a marker.

The paper instructions and the latest PDF differ regarding the 1/16" below the mitre slot, the pdf doesn't mention a measurement, just that it should be below the slot. Although this did not hinder me as the slots in the rail are quite deep, I should have ignored the 1/16" below the mitre gauge slot as the startrite mitre slot is very shallow, I would say 3/16" is more like it. To be fair to Kreg, the offer a phone number to call so you can both ask about bandsaw models, or provide your experience. Top tip is to check the PDF as the inbox instructions may be outdated and have missing errata.

So if you have a startrite, clamp it lower before marking up. Anway, I drilled and tapped it to M8 and used some 12mm button head bolts to attache the rail. The table edge was not straight so I put a thick washer between the rail and the table on each bolt to stand it off slightly to avoid bending the rail.

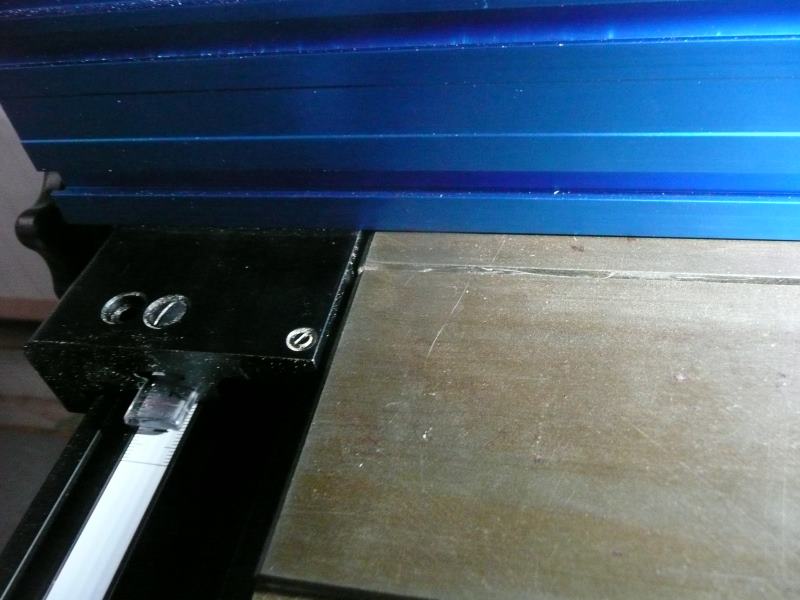

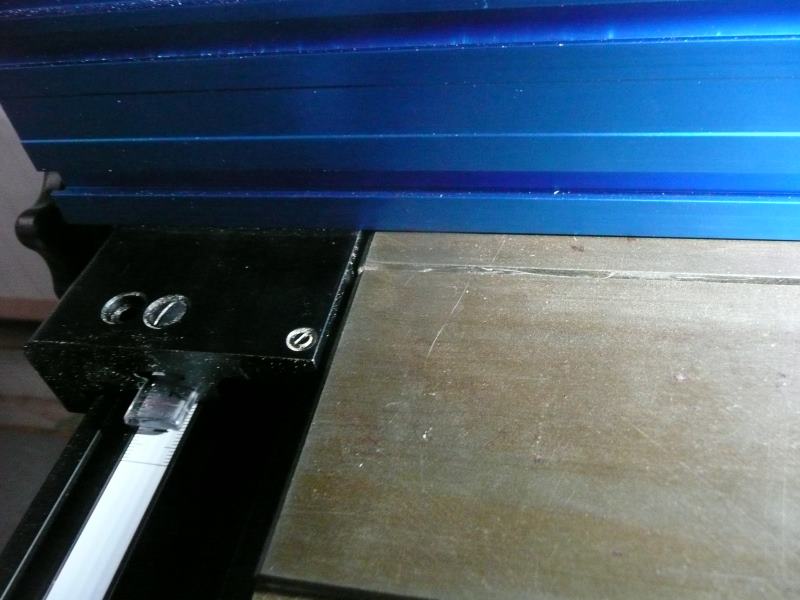

Here it is the rail attached to the front at the specified depth

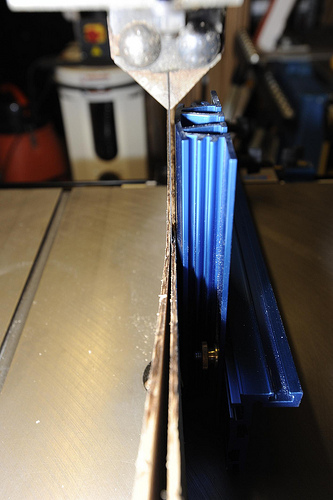

Fitting the fence to the rail is easy enough, no problems, easy to square etc. However, as you can see from the next photo, it leaves a gap under the fence.

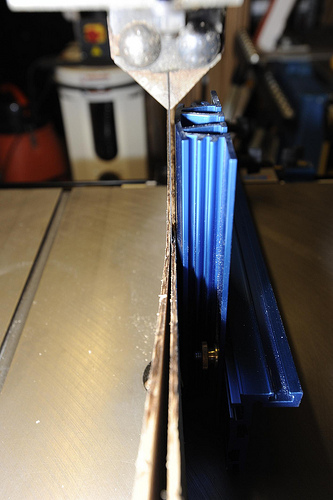

So the the rail was dropped so it was 7/16" below the top of the table using the adjustment allowed by the slots, this worked a treat. Next pic shows a better fit. Now I know the correct height I will make something to attach to the old fence bolt holes underneath the table so that the rail will always go to the same height. This will make blade changing much less of a faff.

The above pic shows 3 screws, the middle screw adjusts the tape cursor. The other two are mirrored on the other side of the fence. The right hand grubs screws are used to help the fence move smoothly on the rail when adjusting and are made out of nylon, a spare set is provided with the kit. the left hand bolts are cap head (just noticed the bolts aren't fitted in this photo!) again nylon so they run smoothly and are to adjust parallelism, i.e to make sure the fence is perpendicular to the table.

These nylon screws are the bits I don't particularly like, but they do seem to work, just about. You have to screw the grub screws in so that about 1/16" is protruding underneath which lifts the fence bracket hence the fence. If you don't, the screw head is proud of the bracket and catches on any stock you pass through the table. The parallel screws seem to have limited travel and are superfluous as the two grub screws also adjust for this plus if you have set the mounting rail parallel to the table, the fence and brackets etc. are machined square so you shouldn't need adjustment. I guess it's a nice to have, but if I could do without both I would, I may play with that later.

I bought the Kreg because it had accessories like the fine adjuster, and t-slots so addition fences and stops could be added. The adjuster works very nicely. I have some stops for other fences that fit but I can make others easily now without trying to clamp it as I did with the old fence. Fence could have done with being 100mm or so longer.

Kreg do a resaw fence that isn't too mad price wise, unlike their stops, I haven't tried it but I found some images of one in use on this forum from member "the wood butcher" selling a Startrite 352.

He makes it look easy, I may take a look at one of those, about £16, however I had thought of two other options for attaching a more conventional tall resaw fence.

First I have a piece of 8mm aluminium plate 500mm long and 150mm high. I could drill four holes that line up with the two T tracks on the face of the plate and use 1/4" UNC countersunk head bolts and T-nuts.

The other way would be to either replace the fence with a different taller extrusion or bolt one to the front. Something like this Valutrack 40 x 160mm extrusion.

The fence bracket helps by having bolts in slots so the height of the T-track in the extrusion can vary a little. The existing t-track used for fixing the bracket is about 40mm from the bottom to the mid point of the slot, and Valutrack is 20mm, not sure it has that amount of adjustment or if there are other options but I think my aluminium plate is the easiest option for me, but alternative, preferably longer fence extrusions seems a future option.

So to summarise, fixing to the front of the table is easy enough. Getting the rail height right using the adjustment slots is a bit of a faff when changing blades but can easily be sorted with a jig or some support bracket underneath set to the required height. The fence is a bit short, not desperately but for the sake of 100mm it is a design fault. The nylon glide grub screws and adjustment bolts do work, but I don't like them at this price. The ruler is only imperial, should provide a combined ruler or an additional metric rule, cost me an extra six quid but the rule is high quality. Very solidly built, good quality extrusions and brackets, easy enough to adjust.The fine adjuster works well and it is easy to attach a variety of commercial and home made stops and jigs.

Cheers

Andy

So I took the plunge and bought the Kreg KMS7200 with microadjuster, total cost about £125.

Sorry about the imperial measurements, it's just easier sometimes when working with US kit.

I wasn't expecting it until next week however it arrived early so I just finished round one of tinkering with it. First impression was quality components.

I already knew I would have to drill the front of the table as the existing fence bolts underneath. So following the instructions, I offered up the rail to the front of the table so the top was 1/16" below the bottom of the mitre gauge slot. I lined up the existing holes in the rail so that the single right hand bolt slot and the one of the three left hand slots did not coincide with any under-table obstruction like a casting web and clamped it into position while I marked the table through the slots with a marker.

The paper instructions and the latest PDF differ regarding the 1/16" below the mitre slot, the pdf doesn't mention a measurement, just that it should be below the slot. Although this did not hinder me as the slots in the rail are quite deep, I should have ignored the 1/16" below the mitre gauge slot as the startrite mitre slot is very shallow, I would say 3/16" is more like it. To be fair to Kreg, the offer a phone number to call so you can both ask about bandsaw models, or provide your experience. Top tip is to check the PDF as the inbox instructions may be outdated and have missing errata.

So if you have a startrite, clamp it lower before marking up. Anway, I drilled and tapped it to M8 and used some 12mm button head bolts to attache the rail. The table edge was not straight so I put a thick washer between the rail and the table on each bolt to stand it off slightly to avoid bending the rail.

Here it is the rail attached to the front at the specified depth

Fitting the fence to the rail is easy enough, no problems, easy to square etc. However, as you can see from the next photo, it leaves a gap under the fence.

So the the rail was dropped so it was 7/16" below the top of the table using the adjustment allowed by the slots, this worked a treat. Next pic shows a better fit. Now I know the correct height I will make something to attach to the old fence bolt holes underneath the table so that the rail will always go to the same height. This will make blade changing much less of a faff.

The above pic shows 3 screws, the middle screw adjusts the tape cursor. The other two are mirrored on the other side of the fence. The right hand grubs screws are used to help the fence move smoothly on the rail when adjusting and are made out of nylon, a spare set is provided with the kit. the left hand bolts are cap head (just noticed the bolts aren't fitted in this photo!) again nylon so they run smoothly and are to adjust parallelism, i.e to make sure the fence is perpendicular to the table.

These nylon screws are the bits I don't particularly like, but they do seem to work, just about. You have to screw the grub screws in so that about 1/16" is protruding underneath which lifts the fence bracket hence the fence. If you don't, the screw head is proud of the bracket and catches on any stock you pass through the table. The parallel screws seem to have limited travel and are superfluous as the two grub screws also adjust for this plus if you have set the mounting rail parallel to the table, the fence and brackets etc. are machined square so you shouldn't need adjustment. I guess it's a nice to have, but if I could do without both I would, I may play with that later.

I bought the Kreg because it had accessories like the fine adjuster, and t-slots so addition fences and stops could be added. The adjuster works very nicely. I have some stops for other fences that fit but I can make others easily now without trying to clamp it as I did with the old fence. Fence could have done with being 100mm or so longer.

Kreg do a resaw fence that isn't too mad price wise, unlike their stops, I haven't tried it but I found some images of one in use on this forum from member "the wood butcher" selling a Startrite 352.

He makes it look easy, I may take a look at one of those, about £16, however I had thought of two other options for attaching a more conventional tall resaw fence.

First I have a piece of 8mm aluminium plate 500mm long and 150mm high. I could drill four holes that line up with the two T tracks on the face of the plate and use 1/4" UNC countersunk head bolts and T-nuts.

The other way would be to either replace the fence with a different taller extrusion or bolt one to the front. Something like this Valutrack 40 x 160mm extrusion.

The fence bracket helps by having bolts in slots so the height of the T-track in the extrusion can vary a little. The existing t-track used for fixing the bracket is about 40mm from the bottom to the mid point of the slot, and Valutrack is 20mm, not sure it has that amount of adjustment or if there are other options but I think my aluminium plate is the easiest option for me, but alternative, preferably longer fence extrusions seems a future option.

So to summarise, fixing to the front of the table is easy enough. Getting the rail height right using the adjustment slots is a bit of a faff when changing blades but can easily be sorted with a jig or some support bracket underneath set to the required height. The fence is a bit short, not desperately but for the sake of 100mm it is a design fault. The nylon glide grub screws and adjustment bolts do work, but I don't like them at this price. The ruler is only imperial, should provide a combined ruler or an additional metric rule, cost me an extra six quid but the rule is high quality. Very solidly built, good quality extrusions and brackets, easy enough to adjust.The fine adjuster works well and it is easy to attach a variety of commercial and home made stops and jigs.

Cheers

Andy