mailee

Established Member

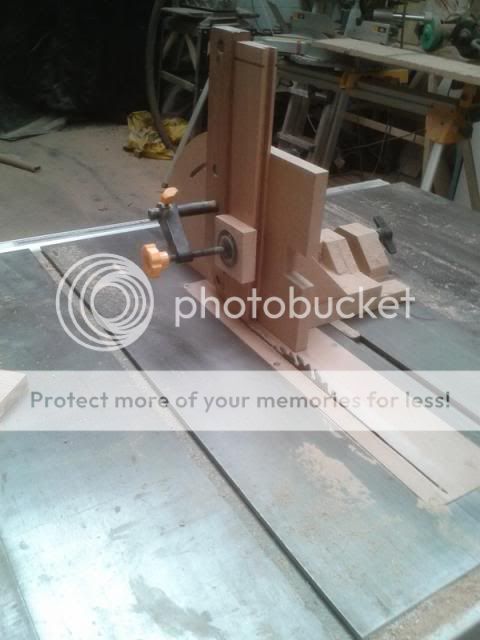

Well with the table and aquarium cabinet finished and not being one to sit on my laurels I started my next commission today. Surprisingly enough it is more AWO units too.  This one is for a run of low cabinets into a corner and on the opposite wall a tall thin book case to fit into an alcove. on the same wall past a doorway a tall cupboard with adjustable shelves. I started by making some of the mouldings that will separate the units. After cutting and machining some 2" oak I rigged a jig on the bench to cut some flutes.

This one is for a run of low cabinets into a corner and on the opposite wall a tall thin book case to fit into an alcove. on the same wall past a doorway a tall cupboard with adjustable shelves. I started by making some of the mouldings that will separate the units. After cutting and machining some 2" oak I rigged a jig on the bench to cut some flutes.

I had four to make and the jig made easy work of them.

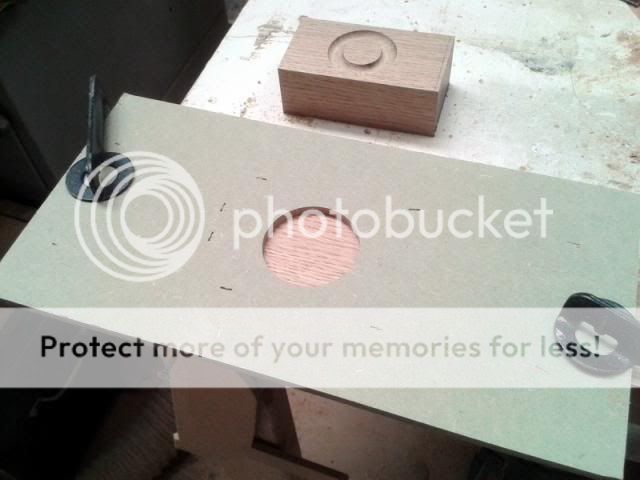

I then cut some squares of 1" to make the feet of the columns. I screwed them to the bench and then ran around them with the router.

I then attached them to the bottom of each column with glue and screws to complete them.

I also got the sides of the cabinets cut out of some veneered MDF before calling it a day.

I had four to make and the jig made easy work of them.

I then cut some squares of 1" to make the feet of the columns. I screwed them to the bench and then ran around them with the router.

I then attached them to the bottom of each column with glue and screws to complete them.

I also got the sides of the cabinets cut out of some veneered MDF before calling it a day.