JonnyD

Established Member

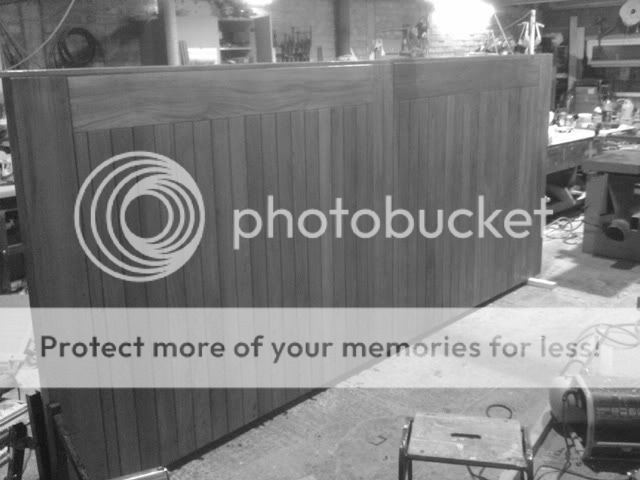

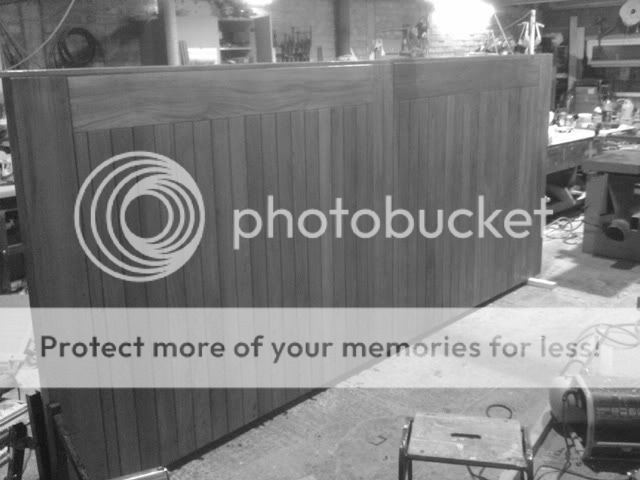

This is a commision for a european oak gate/screen to allow access into a small courtyard which contains 3 barns. The gate is approx 4200 X 1700 X 70mm thick and is pretty heavy ie it take 4 big men to lift it. The wood was bought as well Air dried and it worked really well.

This is the gate in the shop

There are 4 mortices in the bottom rail to take these 90mm wheels

The track is pressed so that it has a half round profile and there is a matching profile on the wheels. You can get ones that you set into concrete but i went for the easy option and used the screw down one. I am very impressed with the rolling gear as you can open and close the gate with 1 finger bit like an altendorf of gates

The gate is guided by 4 40mm nylon bearing rollers. We didnt know quite how this was going to work so decided to make up some temporary plywood plates and then get some metal ones fabricated to suit once the gate was installed

Looking from the courtyard

looking from the outside

The boards are nailed onto the framework using round head ring shank nails with each board being piloted using a jig to make sure they all line up

Just got to get the metal work fabricated and fit a post to the right hand side to attach some bolts and a lock

Thanks for looking

cheers

Jon

This is the gate in the shop

There are 4 mortices in the bottom rail to take these 90mm wheels

The track is pressed so that it has a half round profile and there is a matching profile on the wheels. You can get ones that you set into concrete but i went for the easy option and used the screw down one. I am very impressed with the rolling gear as you can open and close the gate with 1 finger bit like an altendorf of gates

The gate is guided by 4 40mm nylon bearing rollers. We didnt know quite how this was going to work so decided to make up some temporary plywood plates and then get some metal ones fabricated to suit once the gate was installed

Looking from the courtyard

looking from the outside

The boards are nailed onto the framework using round head ring shank nails with each board being piloted using a jig to make sure they all line up

Just got to get the metal work fabricated and fit a post to the right hand side to attach some bolts and a lock

Thanks for looking

cheers

Jon