thick_mike

Wood Shortener

Doingupthehouse":39b6j1ao said:

Yes, that type of thing would work, but that one is too wide. It needs a 15mm hole and the ply is only 15mm wide

Doingupthehouse":39b6j1ao said:

Yup, blasphemous!John Brown":3mtg12wb said:Pocket hole screws? Or is that blasphemous?

I am genuinely shocked by that. I thought that was the weight of a full sheet of 15mm Baltic Birch ply and that is more than I would have guessed was in your piece.thick_mike":20s9hnj3 said:Just weighed the shelves on my bathroom scales and they are 22kg

thick_mike":28x66y2h said:

whiskywill":3gj2hmm7 said:thick_mike":3gj2hmm7 said:

Didn't know Nigel Slater did woodwork. :wink:

Just4Fun":1jyd6n5z said:Having made these shelves, do you think 15mm thick ply was needed or would thinner ply be strong enough?

Doingupthehouse":31f353zt said:I don't see why chemical anchors wouldn't work. I've used them quite a bit including putting some cast iron lights on the wall that weigh over 30kg each. its also how my heavy tool cabinet is fixed to a lightweight block wall along with lots of other stuff in my workshop. They might be overkill, but if it works...

If the positioning is critical, which it will be, some sort of jig to hold them in position while the resin sets can be useful, they can tend to droop a little. I like using the Rawl R-KEM resin. Clean holes are absolutely essential, I blow them out with a compressor.

I wouldn't attempt them at an angle though, but you could have a couple of M6 or M8 studs at the top and fix some grub screws through the top of the shelf to grip them. Once in however, they ain't ever coming out! Easier to grind them flush than try and remove.

Simon

MikeG.":2j00470o said:Doingupthehouse":2j00470o said:I don't see why chemical anchors wouldn't work. I've used them quite a bit including putting some cast iron lights on the wall that weigh over 30kg each. its also how my heavy tool cabinet is fixed to a lightweight block wall along with lots of other stuff in my workshop. They might be overkill, but if it works...

If the positioning is critical, which it will be, some sort of jig to hold them in position while the resin sets can be useful, they can tend to droop a little. I like using the Rawl R-KEM resin. Clean holes are absolutely essential, I blow them out with a compressor.

I wouldn't attempt them at an angle though, but you could have a couple of M6 or M8 studs at the top and fix some grub screws through the top of the shelf to grip them. Once in however, they ain't ever coming out! Easier to grind them flush than try and remove.

Simon

M6.......6mm centred in a 15mm ply shelf. That leaves 4.5mm of ply either side. How important do you think the strength of the stud or the wall is, compared with the strength of that 4.5mm of ply? And it's obviously even worse for the M8 suggestion.

MikeG.":cq02ttl1 said:It's still ridiculous overkill to be using a chemical anchored anything to hold up shelves which would be 100% on 2 screws and plugs. If the idea of straight bits of steel sticking out of the wall appeals as a means of support, just hacksaw the heads off your screws after you've screwed them in. With any stud fitting like this, though, you've got to prevent the shelves just pulling straight off the stud, and that seems an unnecessary complication to deal with when you could just screw through something into the wall and never have to worry again.

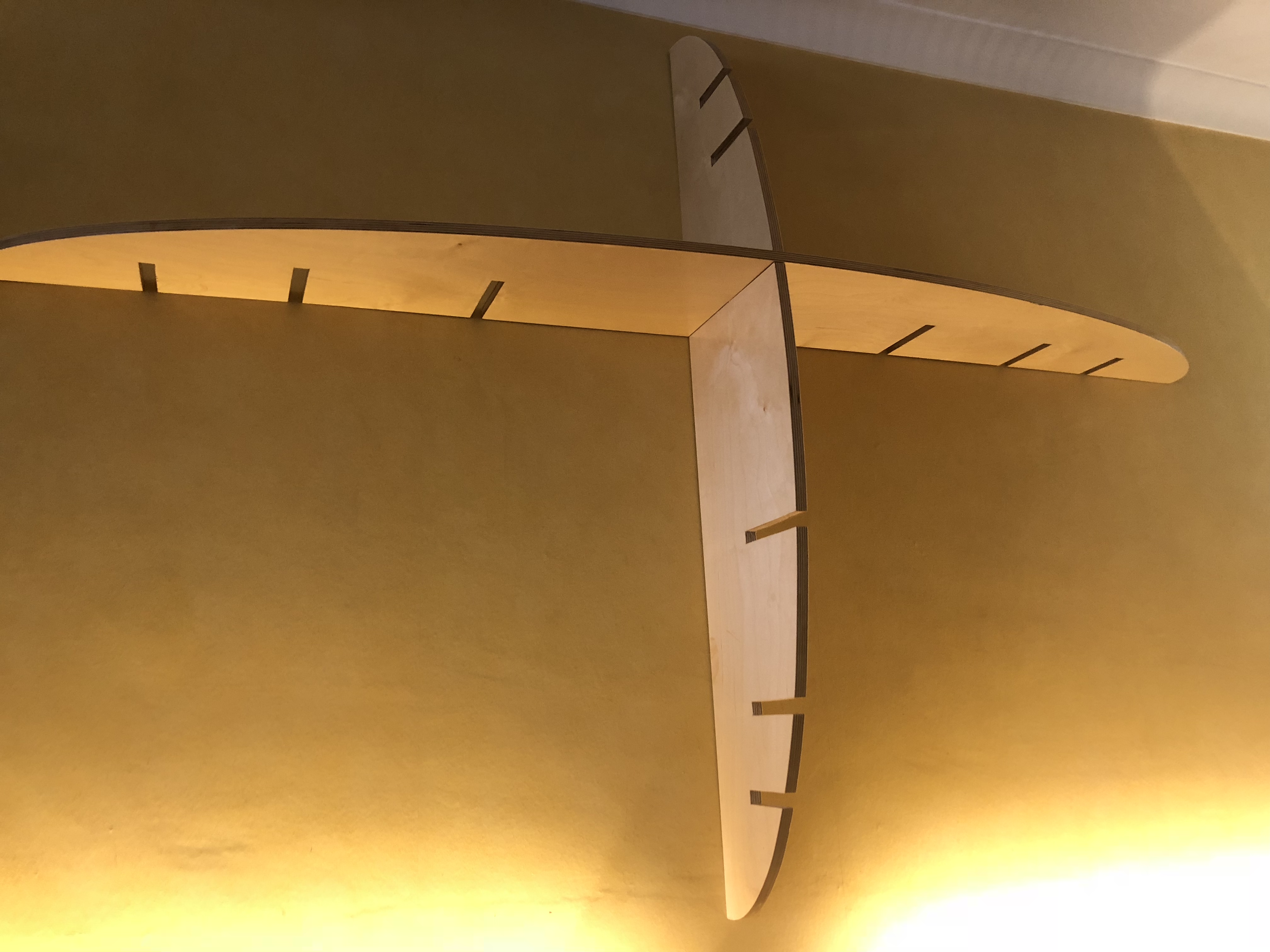

thetyreman":1h855sht said:probably not intentional but this will diffuse sound in a nice way, as well as looking good

thick_mike":384k256y said:thetyreman":384k256y said:probably not intentional but this will diffuse sound in a nice way, as well as looking good

Just wanted to report back on the acoustic properties of the shelves. I installed the shelves on the blank wall opposite my stereo and it has had a marked effect on the acoustics. The room was quite lively (not helped by having guitars hanging on the wall), but the shelves have really cut down on the reverb. That has really improved the sound of my stereo.

Enter your email address to join: