wallace

Established Member

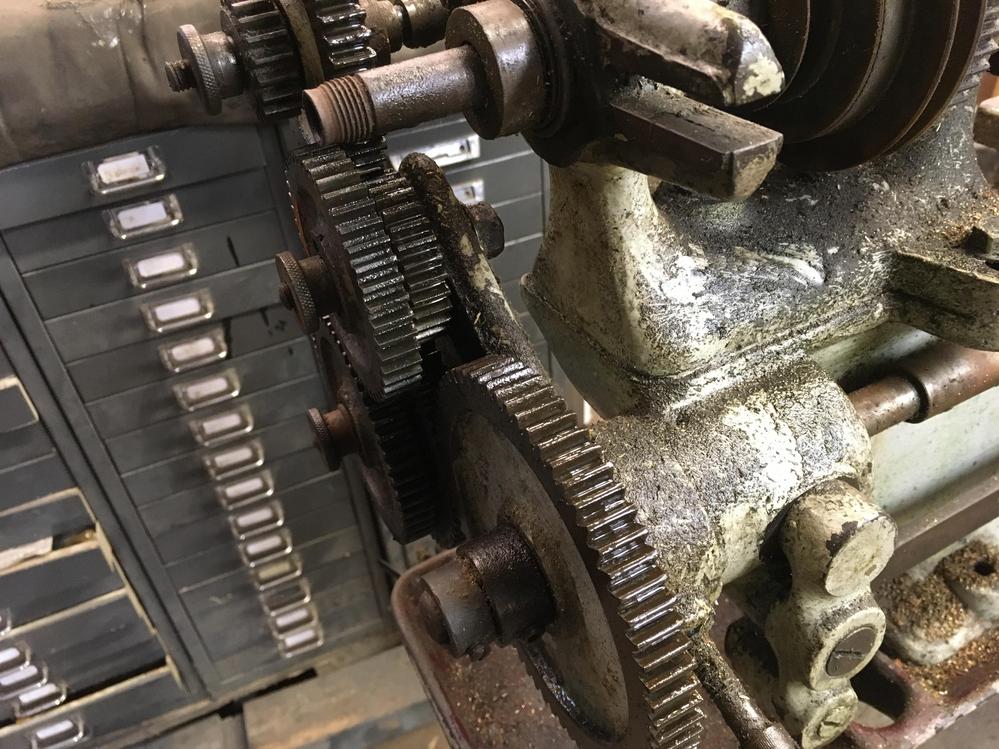

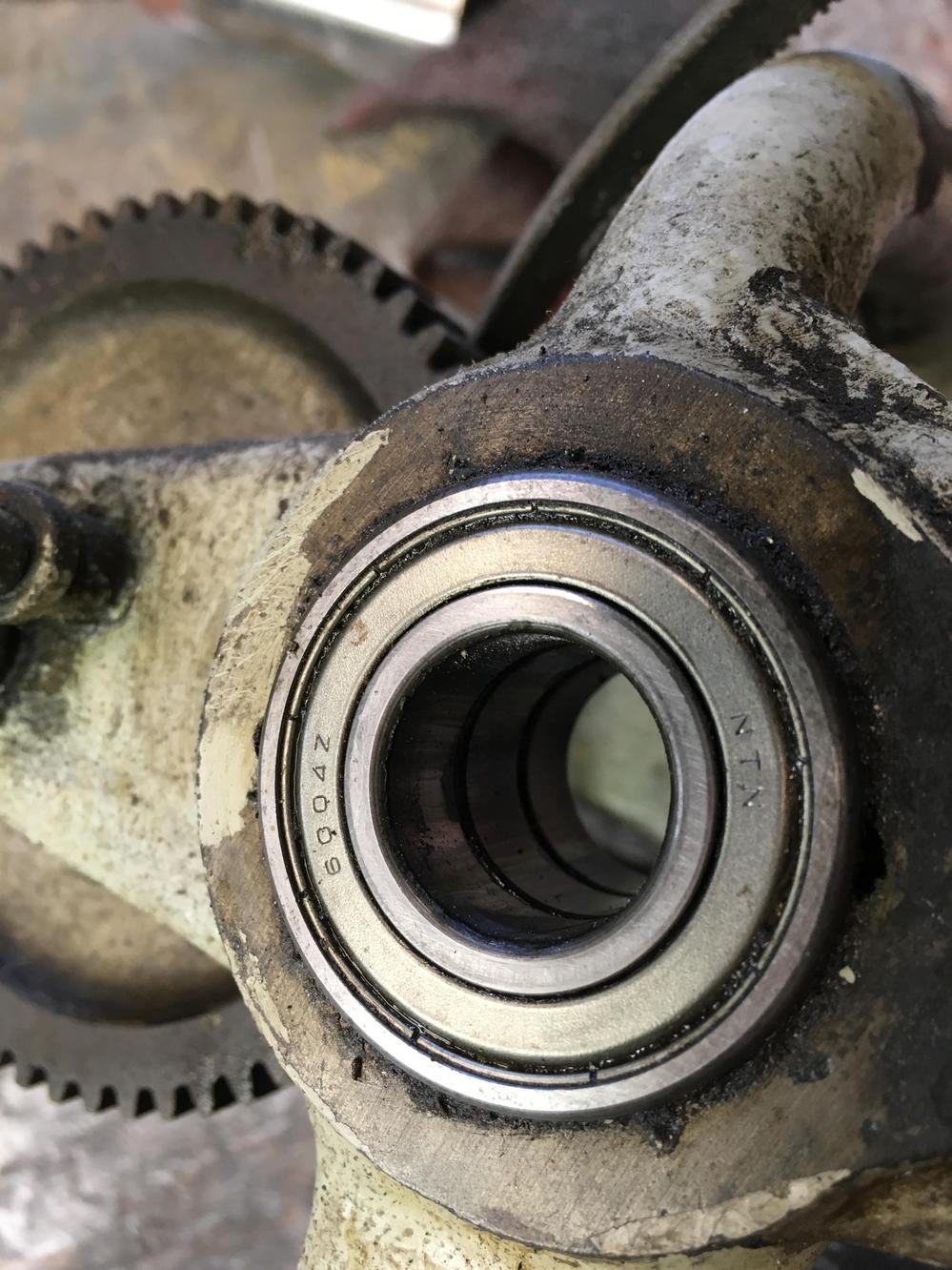

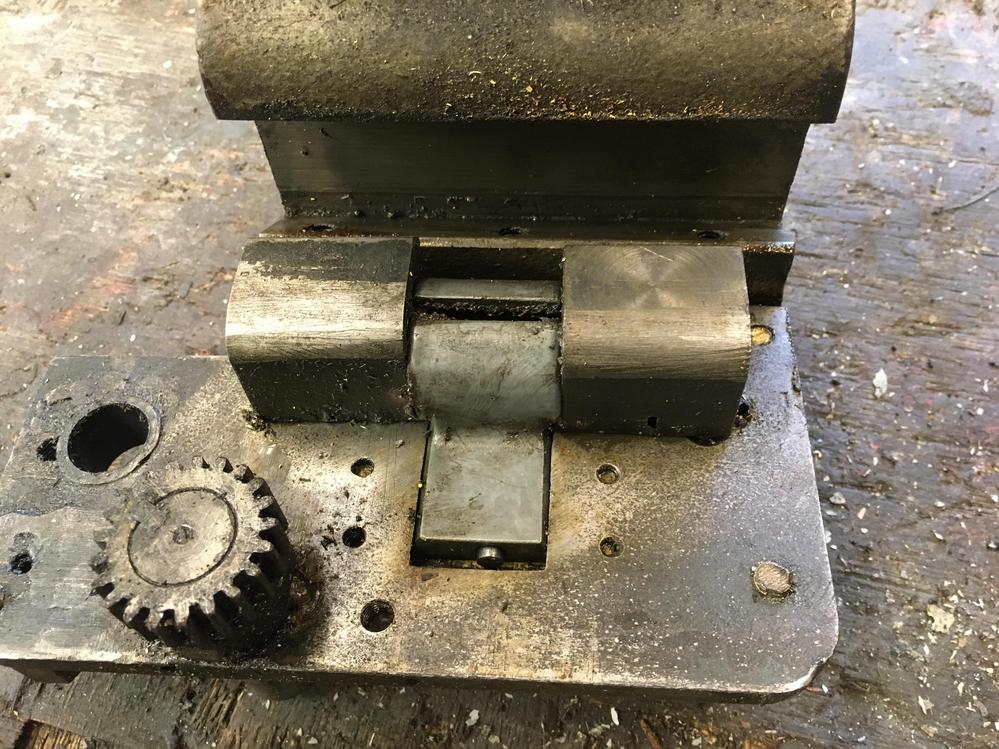

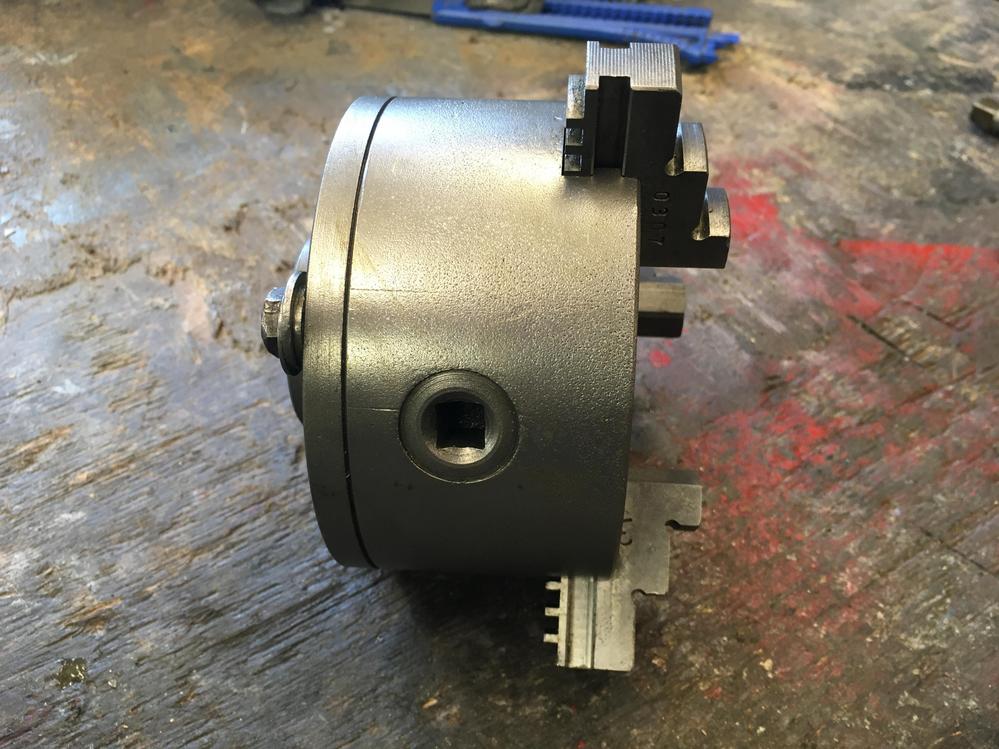

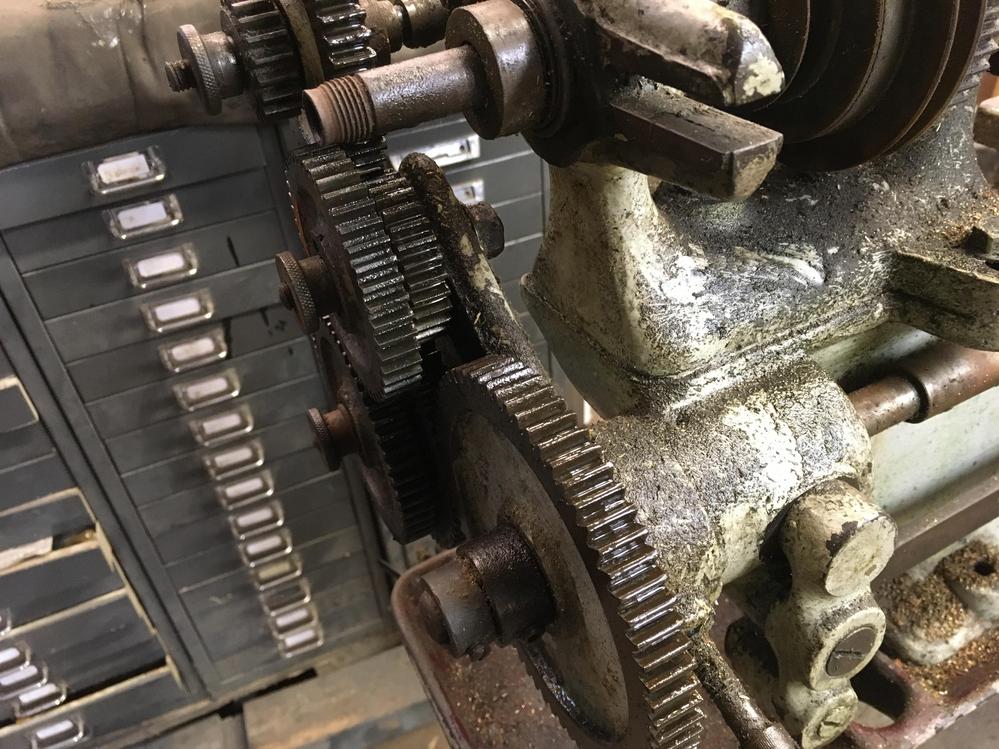

I recently aquired a rough little B lathe. I'm struggling with the change wheels. The old guy that had it said he had never used it for screw cutting. I dont know how the wheels should be arranged to provide a slow motion when the feed is actuated. When I press the feed lever it goes to the right.

I had a look on the drummond group which is a horrible place to navigate.

I had a look on the drummond group which is a horrible place to navigate.