You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dremel type tool

- Thread starter Alexam

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Phil Pascoe

Established Member

I bought a "Skil" one a few years ago in a case with loads of bits, a stand to to hang it and a metre long flexible drive - for £17.50! It's proved just as good as the Dremel (I have one). But as Wiz says above, don't discount a pendant motor if you can find one - they are better. Someone here was selling one a while back - might be worth a look to see if it's still there.

memzey

Established Member

I don't get what the difference is between these and a regular die grinder? If you have an air compressor there are many cheap die grinder kits available and in my experience air tools tend to work well and last longer than portable electronic hand tools.

Alexam

Bandsaw Boxmaker

Initial thread explains what is required. For small inlay work, I doubt that a die grinder would work best, although I am not altogether sure what a die grinder is. I'll look it up.

wizard

Established Member

A die grinder and yes I have one is no good for very small thingsmemzey":dqgfku38 said:I don't get what the difference is between these and a regular die grinder? If you have an air compressor there are many cheap die grinder kits available and in my experience air tools tend to work well and last longer than portable electronic hand tools.

memzey

Established Member

Fair enough. That explains that then! I do see people using dremels for all sorts of things on these fora and for many of those tasks I think a die grinder would work equally well. Now I know what dremels specialise in (finer more intricate work) it makes sense that if you have one to hand you would just use that even if the task isn't particularly fine.

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£26.99 (£1.35 / count)

VEVOX® FFP2 Dust Mask - Set of 20 - Valved Face Masks - Respirator - Protection e.g. for Construction, Building Work, Sanding, Woodworking, Fine Dusts, Aersoles or Particles

SLSK Ventures GmbH (UK)

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£19.46 (£3.89 / count)

£19.99 (£4.00 / count)

Stealth Lite Pro FFP3 Face Masks UK Certified Dust Mask. 99.99% particle filtration, air filter reusable face mask. FFP3 Mask -7 day use per Construction, Woodworking, DIY and Welding Mask

Amazon.co.uk

Rhossydd

Established Member

Mine failed on the third use. No problem getting a refund, but it's not a quality product.graduate_owner":3aeaot64 said:I don't like cheap tools but I bought a Dremel type from Lidl when they had a special offer on. It doesn't get much use - hence the decision to get a cheapie, but it seems to work fine.

Alexam

Bandsaw Boxmaker

I think that a trip to Axminster is called for. They have Dremel and Proxxon, so it would be easier to compare. I need a few other bits, like chisels for inlay and carving as well, so don't have to make a final choice of the main tool just yet

jimi43

Established Member

I have a top of the range Dremel and I recently got a Proxxon at Christmas for use on my CNC machine and the difference is night and day.

The Proxxon is streets ahead of the Dremel in build quality...runout (zero measurable) has on/off switch to start up at set speed and the list goes on and on.

This is the one from Amazon which comes from Germany really fast..no extra duty etc.

Lovely machine and at that price is considerably cheaper than other suppliers.

Jimi

The Proxxon is streets ahead of the Dremel in build quality...runout (zero measurable) has on/off switch to start up at set speed and the list goes on and on.

This is the one from Amazon which comes from Germany really fast..no extra duty etc.

Lovely machine and at that price is considerably cheaper than other suppliers.

Jimi

Alexam

Bandsaw Boxmaker

Thanks Jimi, that's a good price. Do yo use the Proxxon only with your CNC,which presumably would be mounted, or use also using it freehand ?

Alex

Alex

jimi43

Established Member

Alexam":3v2k6scf said:Thanks Jimi, that's a good price. Do yo use the Proxxon only with your CNC,which presumably would be mounted, or use also using it freehand ?

Alex

I tried it out freehand as well and it's great.

Ironically...the best cutoff discs for it are the new Dremel ones! :mrgreen:

Gone are the old days of snapping discs when lateral movement occurs...discs that wear down....

GET ONE OF THESE SETS

I recently made a whole bunch of T-nuts cutting through 10mm sheet aluminium which is renowned for clogging even the best of discs and snapping the old ones. I am still only a few mm into the first disc! No snapping and little wear.

I am lucky enough to be married to a dental nurse and used burrs are ideal for the Proxxon!

Couldn't recommend this tool enough. It's a beauty!

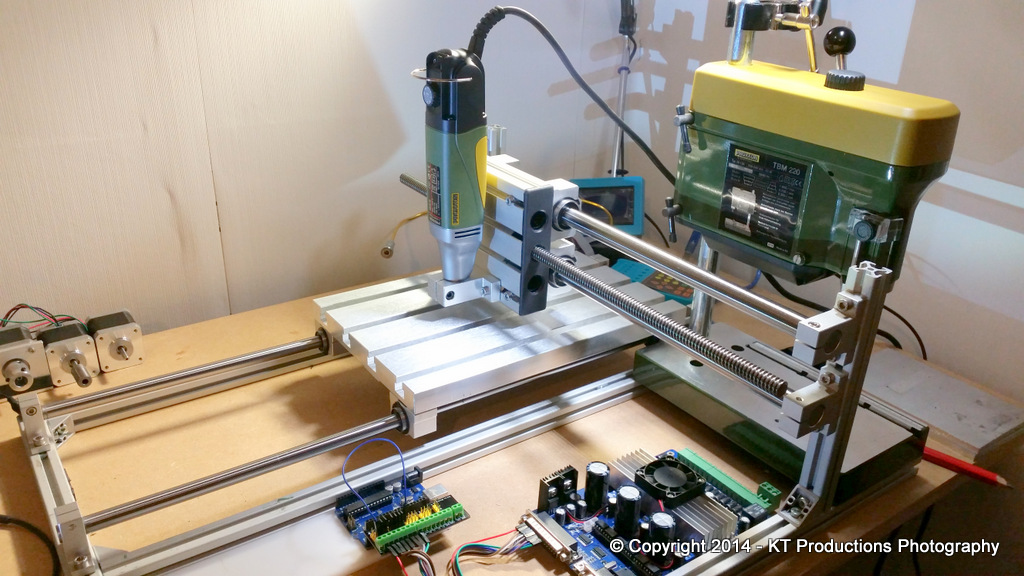

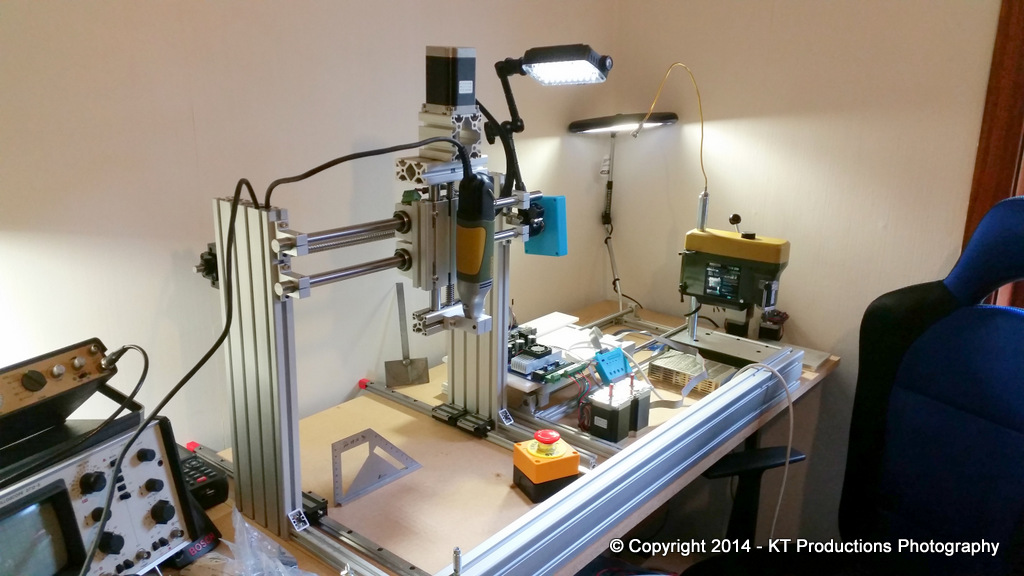

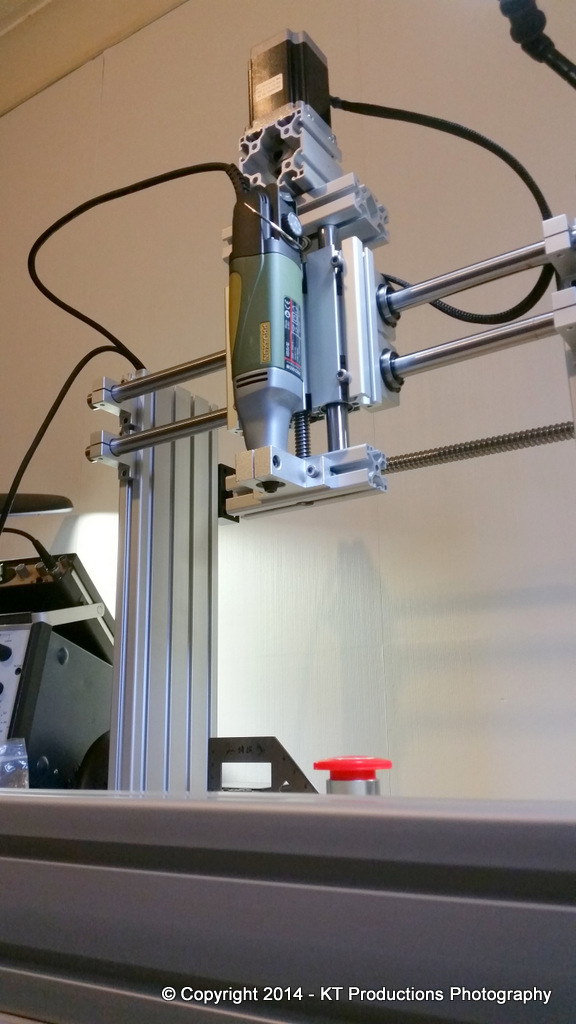

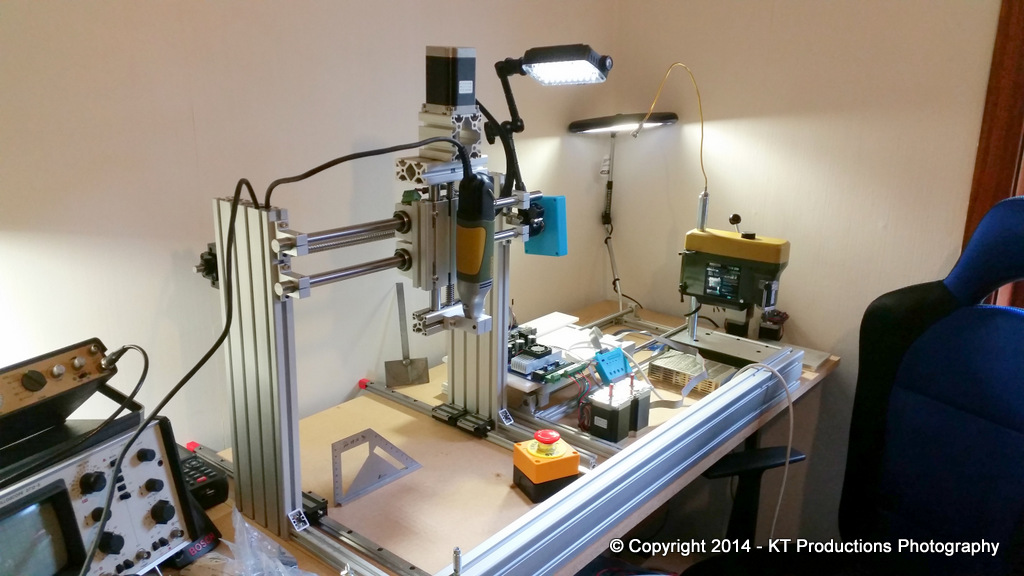

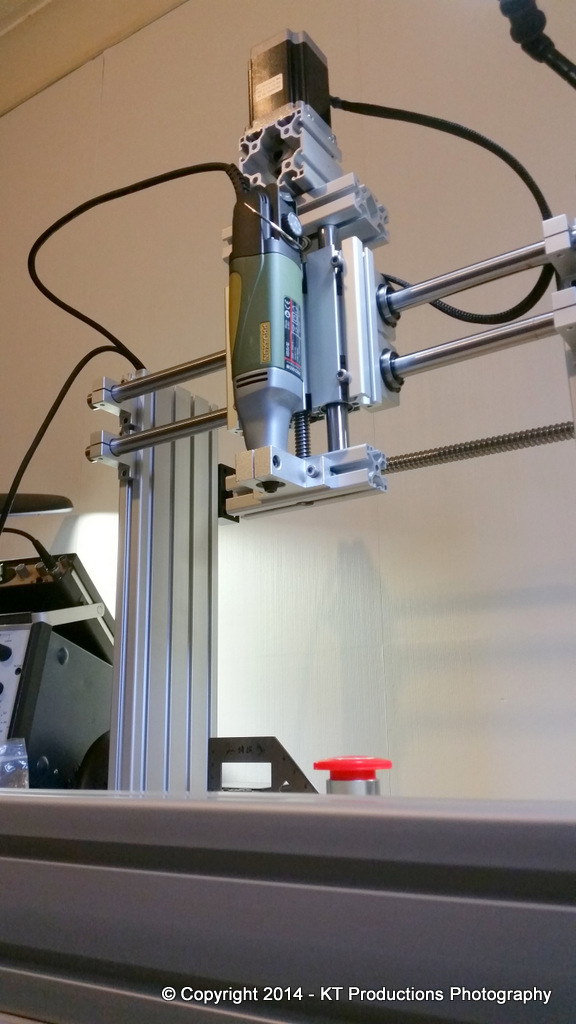

This is my Proxxon mini drill/mill/engraver/saw setup so far....

....and if you want convincing further...check out this guy on this German website...(click under image to go to website)

WEBSITE

I know this is getting out of the bounds of woodworking but if it does this sort of precision work I think inlays should be a breeze! :mrgreen:

(plus he has some uber-cool stuff!!! :mrgreen: )

Cheers

Jimi

Alexam

Bandsaw Boxmaker

That's a fantastic setup Jimi, although I would need it more for routing by hand and I have sen a few router bases, (like the StuMac), that will fit the Proxxon and that may be a good combination. I appreciate your help.

jimi43

Established Member

It's come on a bit since then...

The precision spindle on the Proxxon Professional is critical because I want to do some delicate engraving too in brass and light cuts in steel and any runout will cause a poor cut...

In tests with a fine engraving bit...there was no apparent runout at all...not that I could measure and I suspect that is what you need for clean inlays in wood too.

Best power tool I have bought for quite a while and worth the extra cost.

If I want more power I would need to go to a Kress at three times the price and then to water cooled spindles...but I don't need that (yet!)

Glad to help...if you need any more information, just PM me.

Jimi

The precision spindle on the Proxxon Professional is critical because I want to do some delicate engraving too in brass and light cuts in steel and any runout will cause a poor cut...

In tests with a fine engraving bit...there was no apparent runout at all...not that I could measure and I suspect that is what you need for clean inlays in wood too.

Best power tool I have bought for quite a while and worth the extra cost.

If I want more power I would need to go to a Kress at three times the price and then to water cooled spindles...but I don't need that (yet!)

Glad to help...if you need any more information, just PM me.

Jimi

Alexam":gqcx3h2d said:Hi Rob, which models of Dremel and Proxon do you have and can you say in which way the Proxon is more capable than the Dremel please? What do you mainly use these tools for?

Sorry, I didn't spot your question earlier!

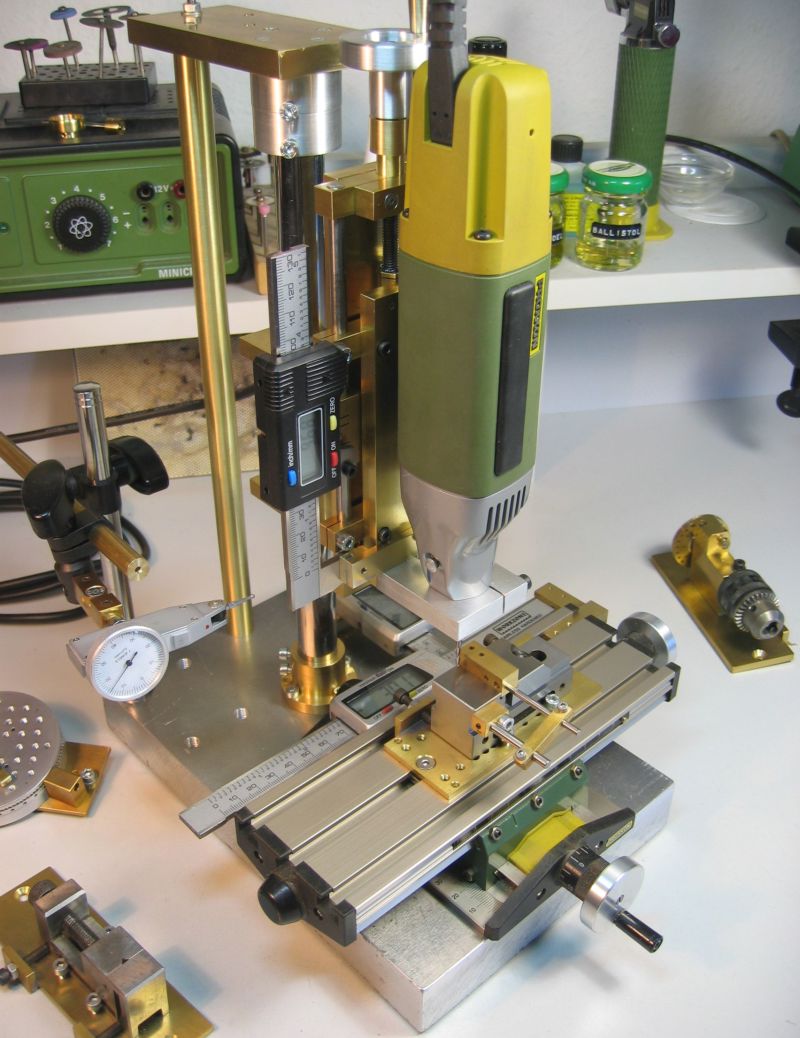

I have the Dremel 4000 and a Proxxon BFW 40/E along with it's stand and XY table.

The Dremel is great for the odd hand held cutting/chopping/grinding jobs and the Proxxon is used for accurate drilling and light milling jobs.

The main difference is the amount of time you can be using it for (before it gets too hot) and the accuracy. The run-out on the Proxxon tools is much better than the Dremel.

The Dremel is very versatile, but I find that a lot of that versatility comes with it's drawbacks, it tries to be too many things rather than being excellent at a few.

I originally used my Dremel in a home built CNC machine, but have since upgraded to a Chinese inverter driven spindle (which gives me ER11 collets) that is more suited to the CNC environment. I did break one Dremel's spindle locking mechanism and the run-out was awful for precision work, hence the upgrade.

jimi43

Established Member

RobCee":3h3avu65 said:Alexam":3h3avu65 said:.........I originally used my Dremel in a home built CNC machine, but have since upgraded to a Chinese inverter driven spindle (which gives me ER11 collets) that is more suited to the CNC environment. I did break one Dremel's spindle locking mechanism and the run-out was awful for precision work, hence the upgrade.

You came along at precisely the right time Rob!

One of my "other" projects will incorporated a "spindle of some sort"....and I was going to assemble one from parts but it's simply too much faffing about and I was looking at the various Asian spindles and VFDs which are around (many many!)...

I think I need about 1.5kW....2.2 is going up to "bigger boy stuff"....and unsure if the bearings..."Germany honestly" or otherwise, would stand up to just air cooled for short jobs...or whether to add water to the mix.

Your guidance on your experience would be most appreciated either here or on a PM.

Cheers

Jimi

Jimi, you have a PM

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 18

- Views

- 2K

- Replies

- 18

- Views

- 2K

- Replies

- 40

- Views

- 6K