Berncarpenter

Established Member

Glynne":1ehz2ew2 said:I had a look at your photobucket and your work is really impressive.

I noticed you had a Knew Concepts saw and I struggled a little with mine for a while until I contacted Matthew of Workshop Heaven. Admittedly I was working with very hard and brittle unsteamed pear but the 9R Skip Reverse blade he recommended was brilliant and I could cut right up to the knife line with ease and have no breakout on the back side. Not sure what blades you use but for a couple of pounds, it might be worth a try given the number of dovetails you are going to be cutting in the near future.

Hope you can post some pictures of your Shwarz Class - I did have a think about it when it was first advertised as I'm in commuting distance from but I'm afraid I need to up my skill levels (a lot) before I would undertake something like that.

Glynne

Thanks for the comment on my work Glynne.

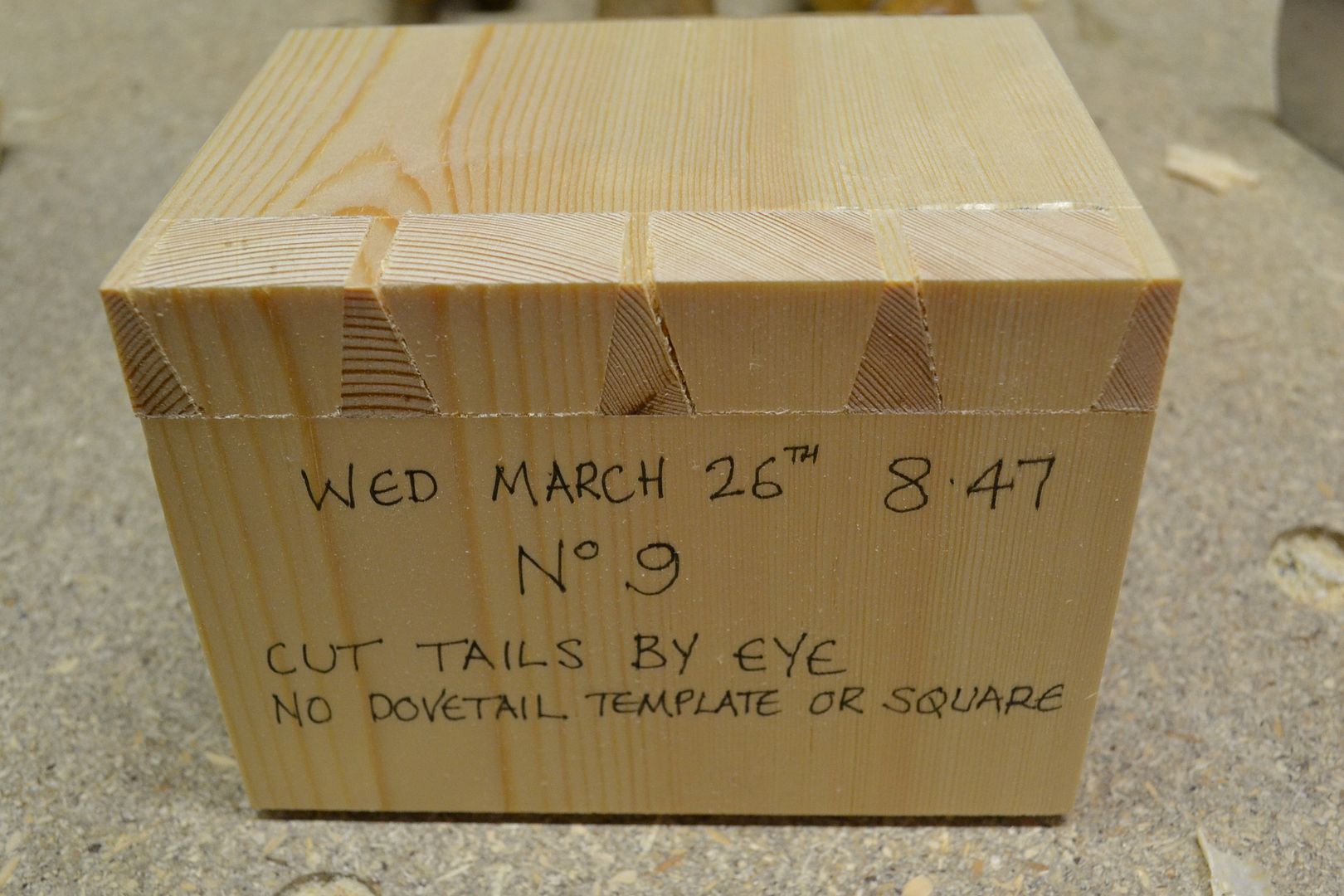

I have some fine blade for the Knew saw and found that for softwood they are not aggressive enough to make really fast cuts that are needed for the dovetail challenge . They are fine for hardwood and especially when using a very fine kerf jap saw. Not sure what skip they are but thanks for the tip i will give those 9R blades a try.I will try and post some of what goes on in the Schwarz class .Not sure if i will have time to stop and take photos as the coarse sounds pretty intense , also i will have to ask if photos are allowed.

Sorry for the slow response i have been out car booting and have been out all day.

Cheers Bern