woodturner_ged

Member

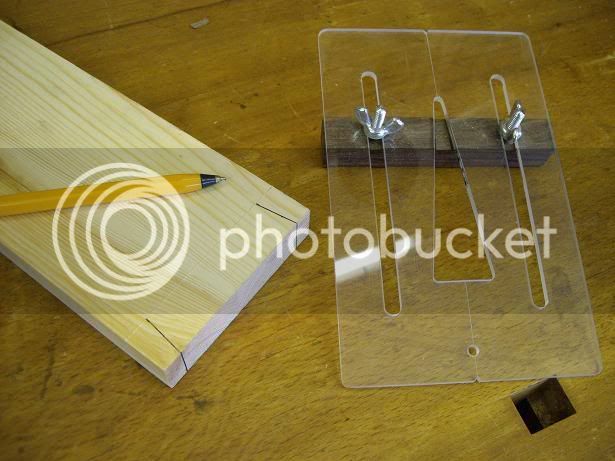

:lol: I AM TRYING TO TEACH MYSELF tohand CUT dovetails there any easy format for laying them out. please?

woodturner ged

woodturner ged

Just to stir things up a bit how often do you mark and cut dovetails with uneven spacing?

woodturner_ged":2uukpiyh said::lol: I AM TRYING TO TEACH MYSELF tohand CUT dovetails there any easy format for laying them out. please?

woodturner ged

woodbloke":2tzfu0p8 said:The ruler scaling technique is the tried and tested method but is a genuine pain in the rear end...I never, ever managed to make the dovetails equal. With a little bit of cunningness you can also using the divider method make your dovetails staggered, ie closer at the edges of the board getting wider towards the middle, as advocated by JK - Rob

John - Jim K was a very good craftsman, I've got a couple of his books...but as a little aside, we both used to live in the same village (Deepcut, nr Camberley) so he probably wasn't very far away from me, but I never met him, more's the pitythe other JK knew a thing or two, and I could always pick up the phone and bend his ear when I needed to. Good old Jim! Sadly missed.

woodturner_ged":g7usihph said::lol: I AM TRYING TO TEACH MYSELF tohand CUT dovetails there any easy format for laying them out. please?

woodturner ged

Enter your email address to join: