Ollie78

Established Member

Hi

I have a couple of small dovetailing issues.

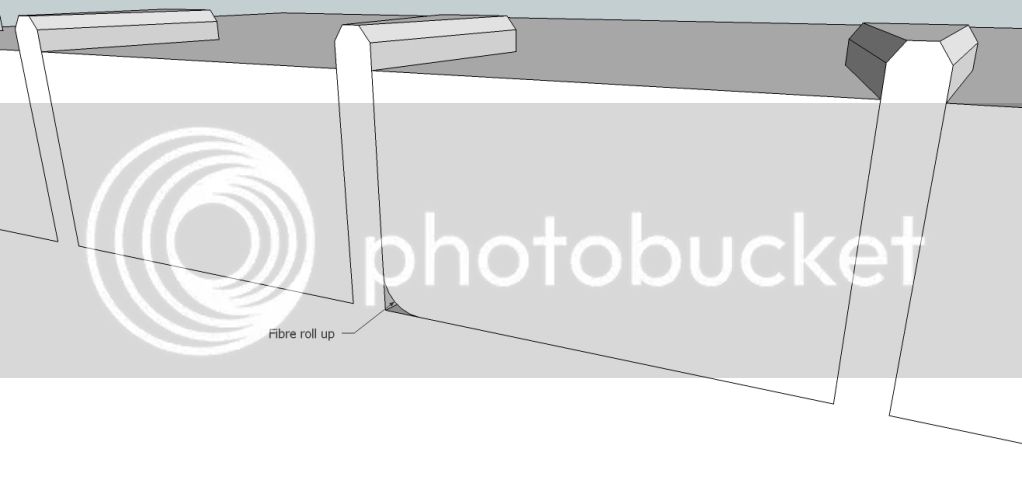

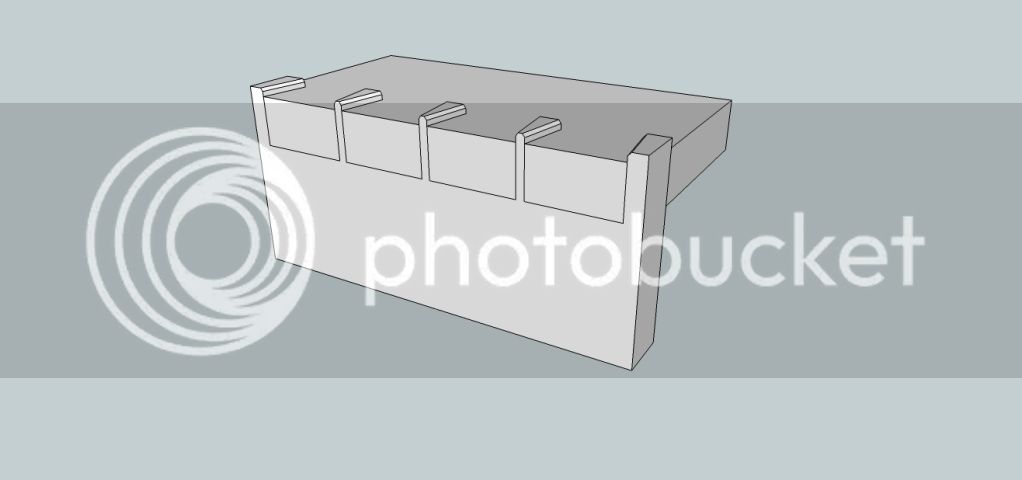

I am making a toolbox using 20mm thick hard maple, 2 boards glued together to get the required width, having cut all the pieces to size I have hand cut the dovetails.

The first question is how tight should the joints be ? currently I can tap them together about half way in with a bit of force, they begin to squeak and bind up at this point, of course I know that really they should only go together once for a good joint.

Should I make them looser so they slide together or trust that when I clamp them up they will go in ? I am a bit worried that I could end up stuck at three quarters in and can`t move them in or out...

The other thing is that since I cut the panels and joints some of the boards have developed a slight cup. Only very small but it is causing a problem lining up the joints . Is there any tricks to getting the joints in? I am hoping that when I assemble the case the joints will `pull` the slight cup out. Is the slight cupping causing the tightness issue ?

Any advice appreciated, I don`t want to **** it up as the wood is not cheap and I have already invested a lot of time in cutting the joints.

Ollie

I have a couple of small dovetailing issues.

I am making a toolbox using 20mm thick hard maple, 2 boards glued together to get the required width, having cut all the pieces to size I have hand cut the dovetails.

The first question is how tight should the joints be ? currently I can tap them together about half way in with a bit of force, they begin to squeak and bind up at this point, of course I know that really they should only go together once for a good joint.

Should I make them looser so they slide together or trust that when I clamp them up they will go in ? I am a bit worried that I could end up stuck at three quarters in and can`t move them in or out...

The other thing is that since I cut the panels and joints some of the boards have developed a slight cup. Only very small but it is causing a problem lining up the joints . Is there any tricks to getting the joints in? I am hoping that when I assemble the case the joints will `pull` the slight cup out. Is the slight cupping causing the tightness issue ?

Any advice appreciated, I don`t want to **** it up as the wood is not cheap and I have already invested a lot of time in cutting the joints.

Ollie