Good day

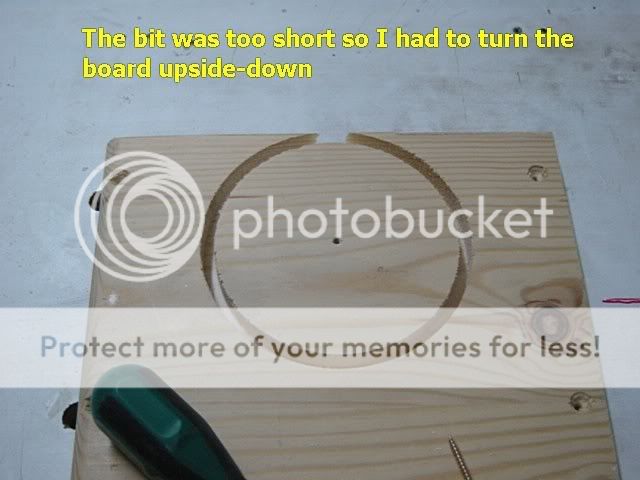

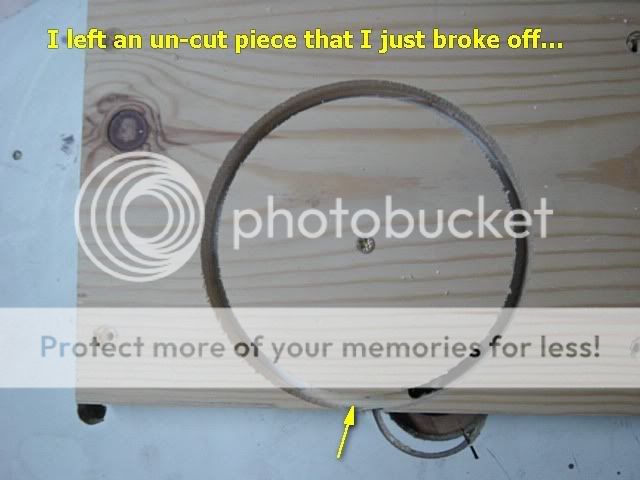

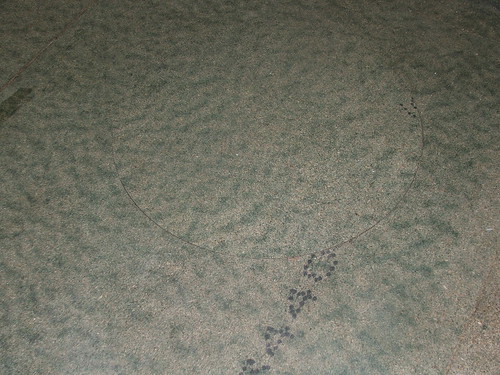

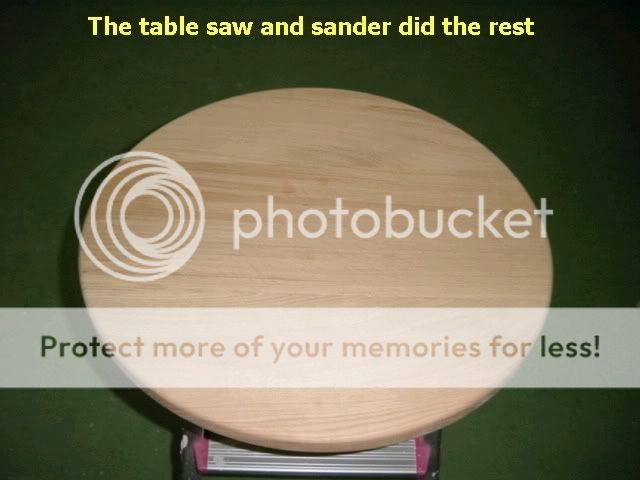

I had to cut 110 mm diameter wheel to plug some hole.

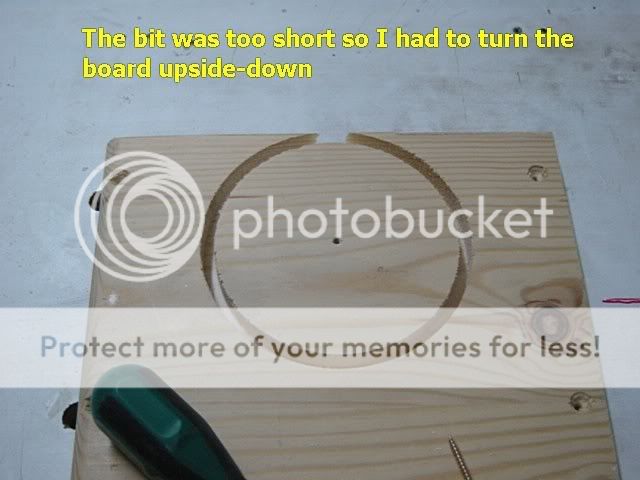

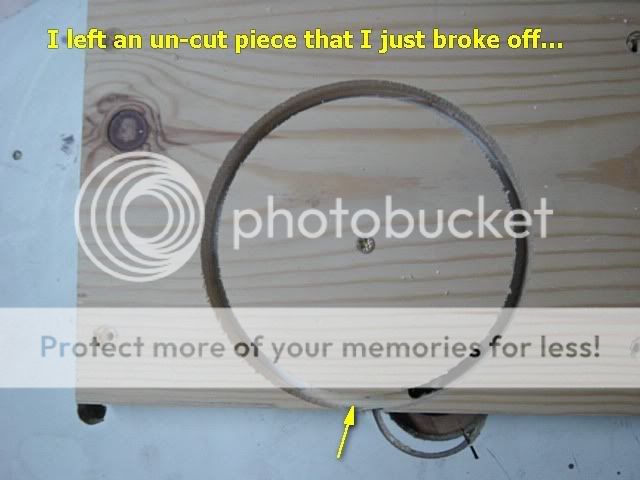

I used 6 mm bit and using the router lift, I lifted the bit till I heard the first "Eeeeeeee" (you know what I mean) and turned the board one round...turned the lift one round and the board one round and so on...

Regards

niki

I had to cut 110 mm diameter wheel to plug some hole.

I used 6 mm bit and using the router lift, I lifted the bit till I heard the first "Eeeeeeee" (you know what I mean) and turned the board one round...turned the lift one round and the board one round and so on...

Regards

niki