I'm about to build a traditional bookcase in English Oak (there will be a WIP thread with piccies) but one thing that is puzzling me is how to create a cornice. I would like something similar to this..........

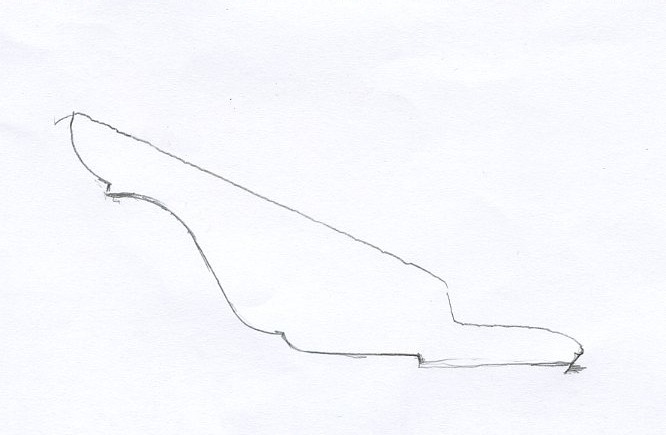

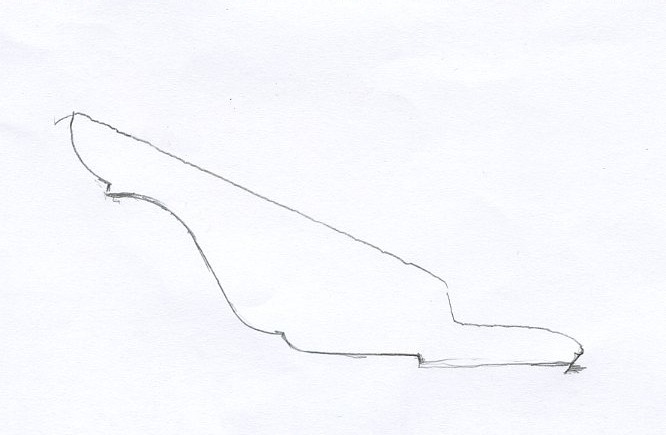

...... which is on an existing piece of furniture. The dentition and rounded part below is no problem, but I can't work out how the cornice itself is cut. I've looked at the cornice cutters on Wealden's site but none seem to match. This is a profile of the complete cornice.

I have a router table but not a spindle moulder. The end result doesn't have to be an exact match for the one shown - just something in the same style. I don't want to buy it in as I want to ensure the wood matches what I already have.

Any ideas?

...... which is on an existing piece of furniture. The dentition and rounded part below is no problem, but I can't work out how the cornice itself is cut. I've looked at the cornice cutters on Wealden's site but none seem to match. This is a profile of the complete cornice.

I have a router table but not a spindle moulder. The end result doesn't have to be an exact match for the one shown - just something in the same style. I don't want to buy it in as I want to ensure the wood matches what I already have.

Any ideas?