Black Magic Detail

Established Member

As requested A WIP ,taken from a post we put up on a car detailing forum .

Hi all, we had an order from an existing customer who owns a mini luxury container filled with Genesis wax and now wants one similar to the one he has in design and wood types ,this time filled with Sirius show wax .

So we decided to give you a write up on how a BMD luxury pot is created.

First we select the woods to be used this time its a walnut base with a cherry lid ,our 2 pieces of wood to create the container .

walnut 80mmx80mmx70mm

Cherry 80mmx80mmx35mm

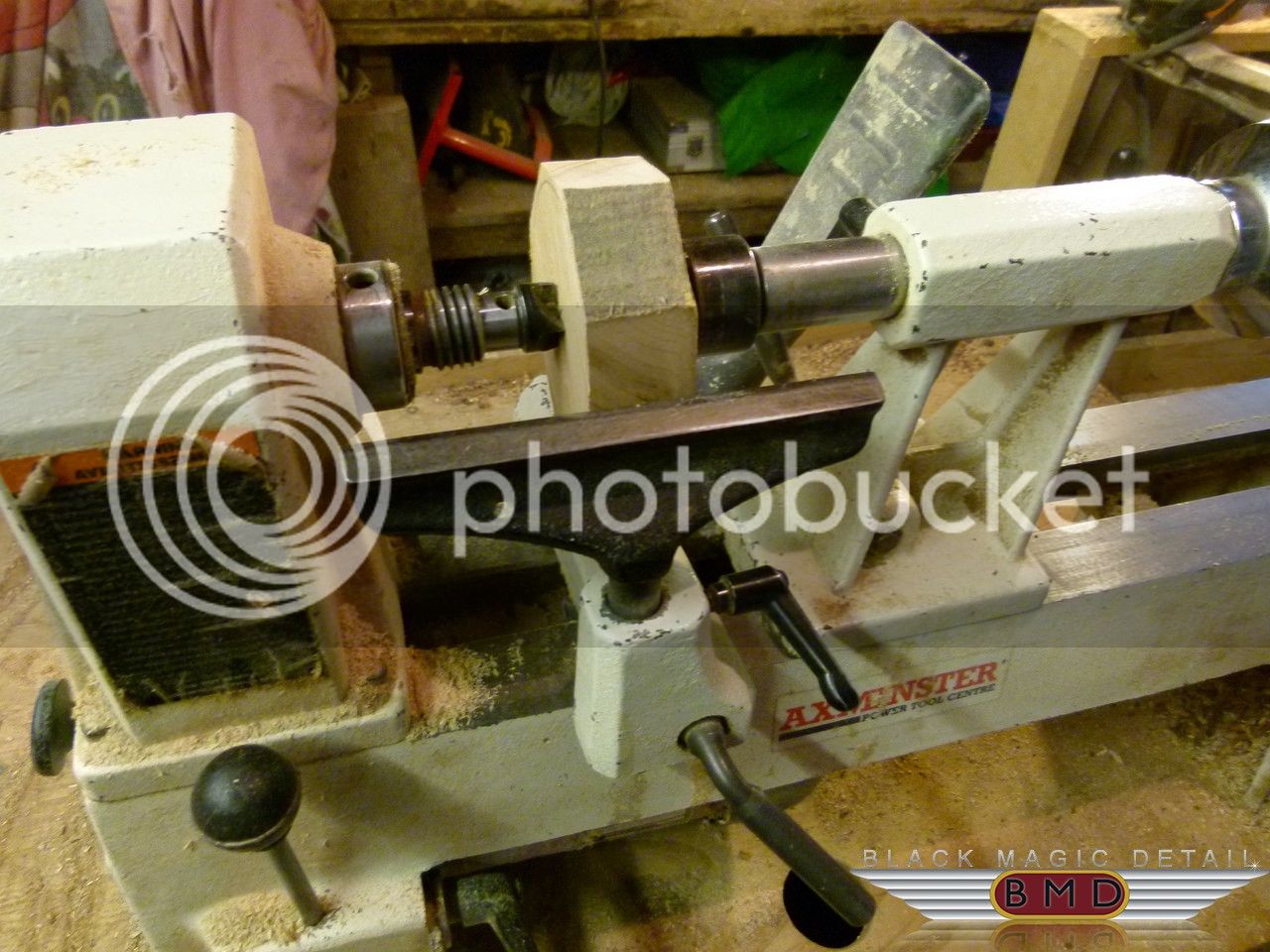

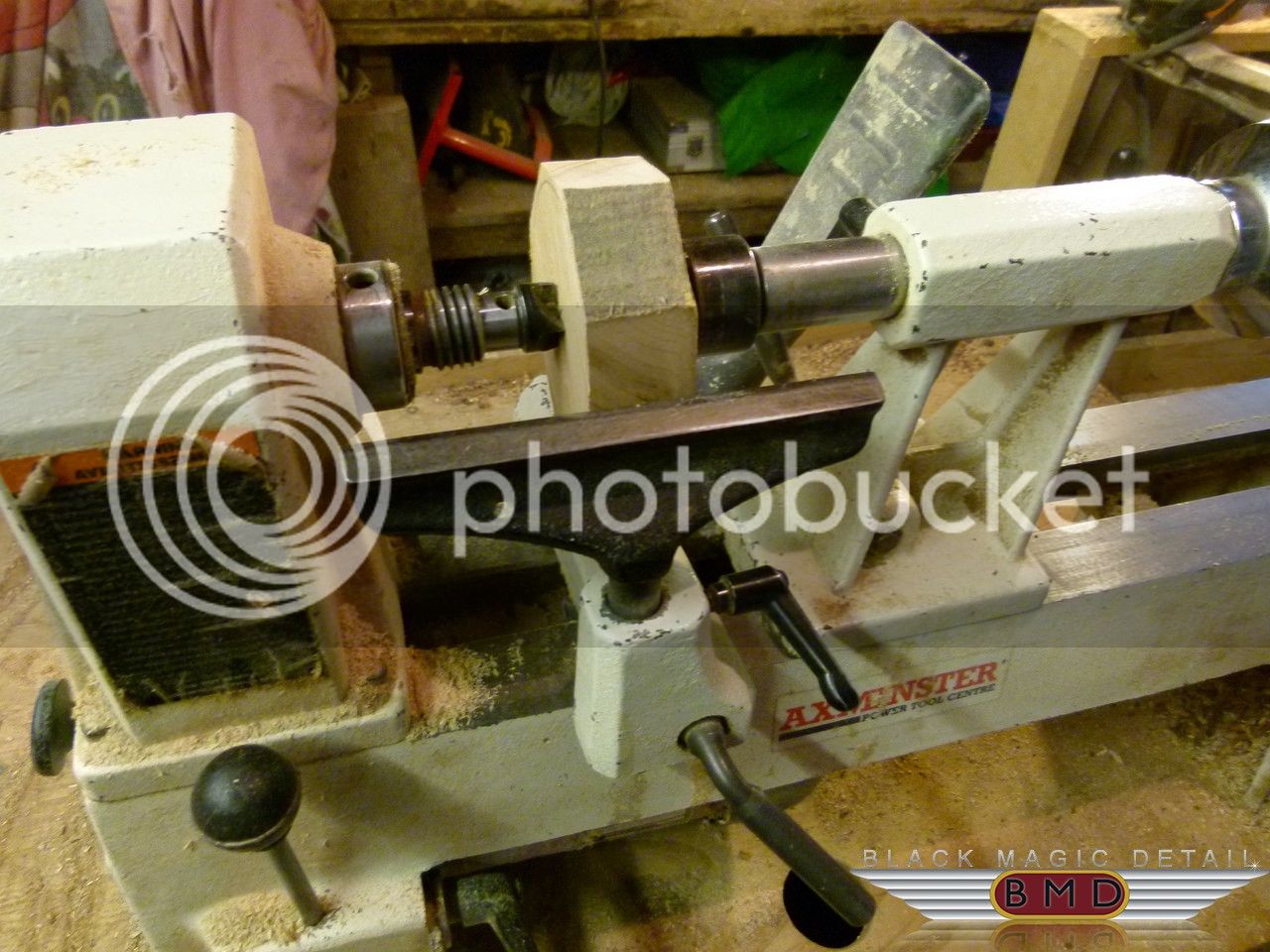

now we remove the 90o angles for easier turning

Now before any turning ,safety first ,dust mask as some wood types have toxic dust ! and full face protection as sometimes a piece of wood will come off the lath at 1500 RPM and smack you in the face ,the last time was a piece of oak about 1.5 KG that gave me a thump in the face shield !!

Lid now set in the lathe ready for turning

Lid now turned roughly round and a dovetail made on the end for attaching to the chuck

lid now attached to the chuck to allow the inside part of the lid to be made

internal part of the lid turned out

Internal part of the lid now sanded with 6 grades of paper then oiled and waxed.

Lid put to the side for now ,time to start turning the walnut base

Walnut base now ready for turning

Again roughly turned round and a dovetail made for chuck attachment

Base turned round and fitted to the chuck then the lip for the lid and recess for the O-ring is made.

An O-ring made to measure.

O-ring fitted to recess

Lid checked for air tight fitment .

Lid fitted to base

Base turned down to roughly the size of the lid

Lid removed and internal space to hold wax is then turned out

Calculations used to work out internal volume ,this time 90ml

Internal part of the base is then given 3 coats of sealer to prevent any absorption between the wood and wax .

The lid is now refitted to the base to finish the external shape then sanded through 6 grades of paper and coated with oil and wax

Time to finish the top of the lid ,the lid is fitted to a jam chuck

Final shape turned,sanded ,oiled and waxed, lid now finished

Time to finish the bottom of the base where it was attached to the chuck ,base fitted to a jam chuck.

Bottom of the base turned down and checking that it won't rock around when its standing due to a high part in the center .

Bottom of the baes now sanded ,oiled and waxed ,base now finished

LSP for today tung oil and BMD wood wax.:lol::lol::lol:

Finished shots ,Mini Luxury Wax Container.

Already to be filled with Sirius show wax .

Thanks for reading another write up from BMD ,a bit of a change this time.

all comments and questions welcome

Remember the Mini range of luxury pots are available on our online store filled with the wax of you choice from only £65

Stevie BMD

Hi all, we had an order from an existing customer who owns a mini luxury container filled with Genesis wax and now wants one similar to the one he has in design and wood types ,this time filled with Sirius show wax .

So we decided to give you a write up on how a BMD luxury pot is created.

First we select the woods to be used this time its a walnut base with a cherry lid ,our 2 pieces of wood to create the container .

walnut 80mmx80mmx70mm

Cherry 80mmx80mmx35mm

now we remove the 90o angles for easier turning

Now before any turning ,safety first ,dust mask as some wood types have toxic dust ! and full face protection as sometimes a piece of wood will come off the lath at 1500 RPM and smack you in the face ,the last time was a piece of oak about 1.5 KG that gave me a thump in the face shield !!

Lid now set in the lathe ready for turning

Lid now turned roughly round and a dovetail made on the end for attaching to the chuck

lid now attached to the chuck to allow the inside part of the lid to be made

internal part of the lid turned out

Internal part of the lid now sanded with 6 grades of paper then oiled and waxed.

Lid put to the side for now ,time to start turning the walnut base

Walnut base now ready for turning

Again roughly turned round and a dovetail made for chuck attachment

Base turned round and fitted to the chuck then the lip for the lid and recess for the O-ring is made.

An O-ring made to measure.

O-ring fitted to recess

Lid checked for air tight fitment .

Lid fitted to base

Base turned down to roughly the size of the lid

Lid removed and internal space to hold wax is then turned out

Calculations used to work out internal volume ,this time 90ml

Internal part of the base is then given 3 coats of sealer to prevent any absorption between the wood and wax .

The lid is now refitted to the base to finish the external shape then sanded through 6 grades of paper and coated with oil and wax

Time to finish the top of the lid ,the lid is fitted to a jam chuck

Final shape turned,sanded ,oiled and waxed, lid now finished

Time to finish the bottom of the base where it was attached to the chuck ,base fitted to a jam chuck.

Bottom of the base turned down and checking that it won't rock around when its standing due to a high part in the center .

Bottom of the baes now sanded ,oiled and waxed ,base now finished

LSP for today tung oil and BMD wood wax.:lol::lol::lol:

Finished shots ,Mini Luxury Wax Container.

Already to be filled with Sirius show wax .

Thanks for reading another write up from BMD ,a bit of a change this time.

all comments and questions welcome

Remember the Mini range of luxury pots are available on our online store filled with the wax of you choice from only £65

Stevie BMD