mailee

Established Member

I am awaiting the arrival of the veneered Oak sheets so in the meantime I am busying myself with a couple of raised panel doors for a cupboard.

I got the frames cut to length and all the mortices and tennons but was having trouble with the mitres. After asking on here about the technique I finally got them pretty good:

I found the centre rail was the hardest to accomplish but got there in the end:

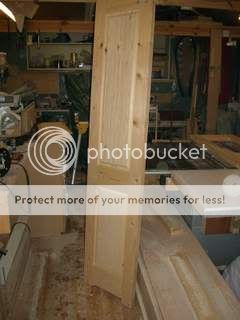

I ended up tonight with one frame complete and ready for the panel:

It has been a while since I made a large door like this without using the Rail and stile cutters in my table. This job was just a bit too big for those as they are only for small cabinet doors. Should get a little more done tomorrow, although I am going to see someone about my website that is in progress. Will keep you posted. :wink:

I got the frames cut to length and all the mortices and tennons but was having trouble with the mitres. After asking on here about the technique I finally got them pretty good:

I found the centre rail was the hardest to accomplish but got there in the end:

I ended up tonight with one frame complete and ready for the panel:

It has been a while since I made a large door like this without using the Rail and stile cutters in my table. This job was just a bit too big for those as they are only for small cabinet doors. Should get a little more done tomorrow, although I am going to see someone about my website that is in progress. Will keep you posted. :wink: