Yojevol

Clocking on

It was back in April that MikeG posed the question 'Has anybody made a wooden clock?' and I was able to report that I had started one. The project lay dormant until a couple of weeks ago when I dusted it off and started to make the frame.

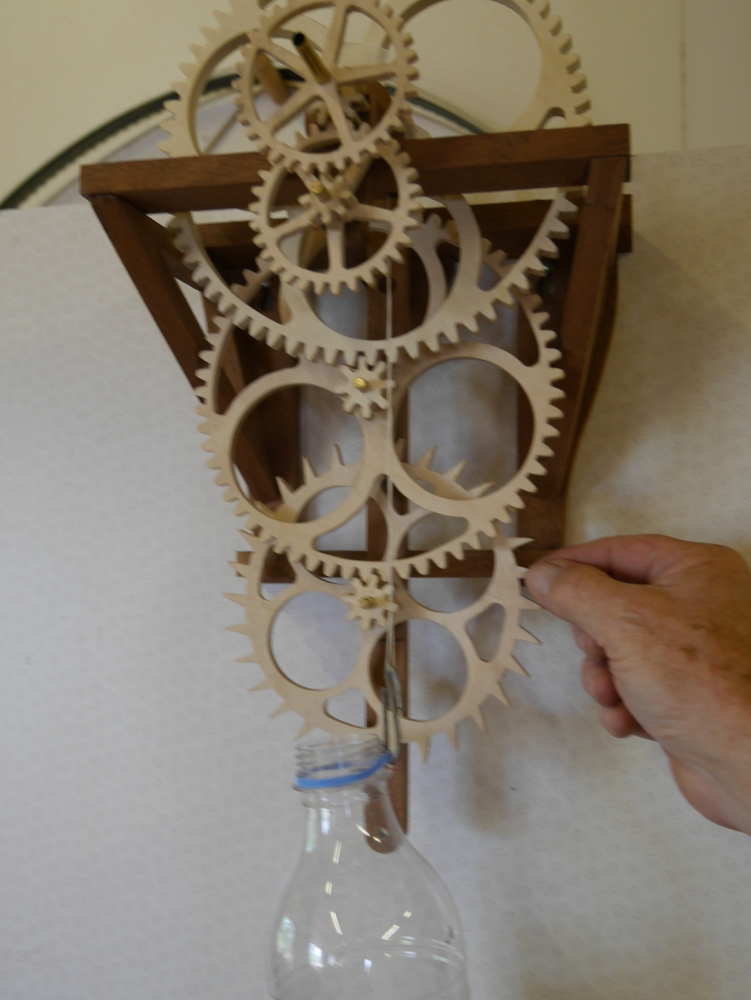

The gears and pinions were made in the initial spurt of enthusiasm. This is what they look like:-

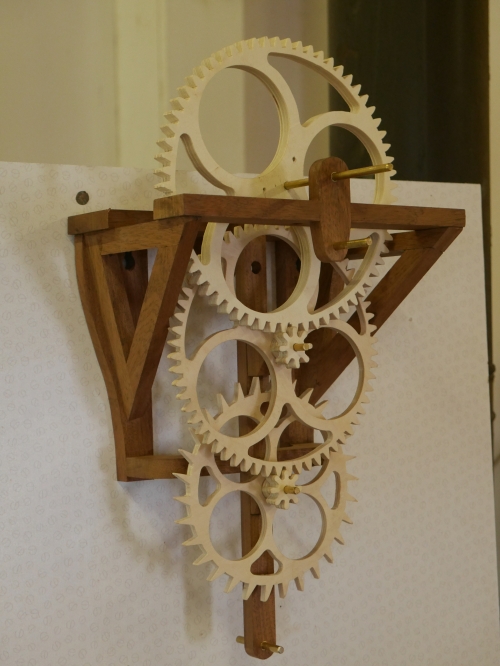

The frame has been made out of mahogany from an old office desk drawer. Here it is complete with its brass shafts in place:-

It departs slightly from Clayton Boywer's original design in that the central vertical support (with the 3 shafts) is tied back to the wall plates to give added rigidity.

It departs slightly from Clayton Boywer's original design in that the central vertical support (with the 3 shafts) is tied back to the wall plates to give added rigidity.

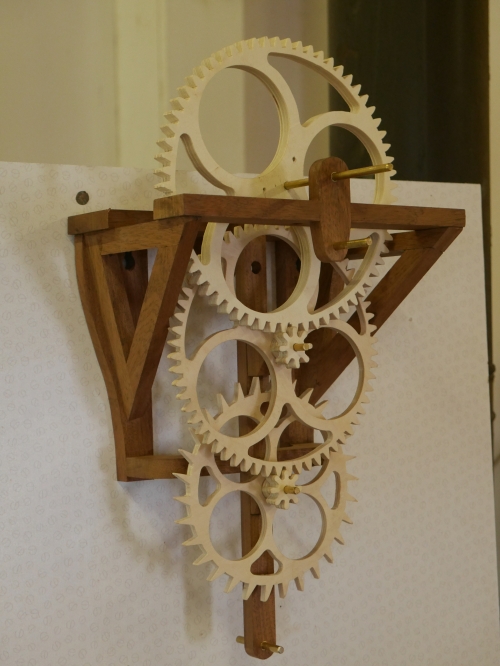

Having got the frame made I could then mount the main gear train and give them a twirl:-

Amazingly the all ran together nicely. I had previously run individual gear/pinion combinations on a lash up frame so I was reasonably confident of a good result.

Amazingly the all ran together nicely. I had previously run individual gear/pinion combinations on a lash up frame so I was reasonably confident of a good result.

The second train of the 2 smaller gears provides motion to the hour hand. These are proving a bit more problematic. They're binding up frequently, so I'll leave that aspect to the next report.

Brian

The gears and pinions were made in the initial spurt of enthusiasm. This is what they look like:-

The frame has been made out of mahogany from an old office desk drawer. Here it is complete with its brass shafts in place:-

Having got the frame made I could then mount the main gear train and give them a twirl:-

The second train of the 2 smaller gears provides motion to the hour hand. These are proving a bit more problematic. They're binding up frequently, so I'll leave that aspect to the next report.

Brian