Jen, if you have a drill press all you need is this expensive bit of kit

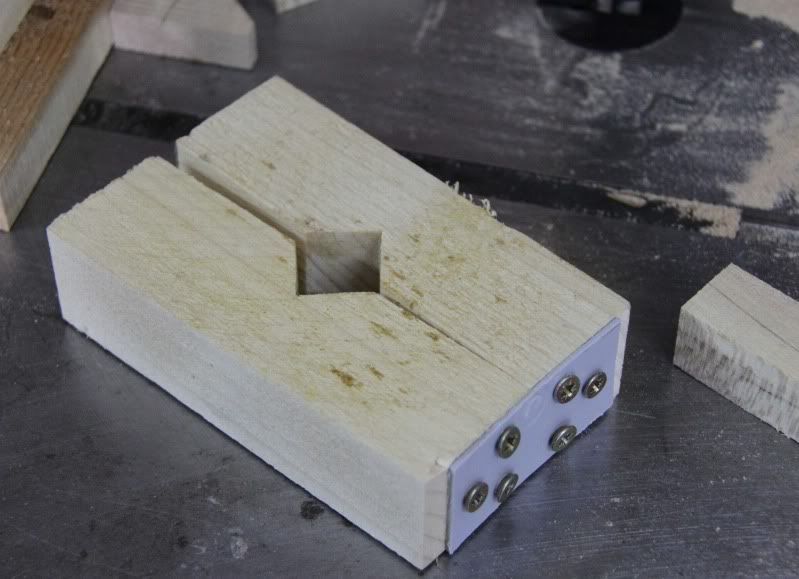

Some scrap wood. A piece of plastic, an old credit card will do and a few wood screws. If the blank is smaller than the hole just put a sliver of wood in to pack it out. If it's slightly too big just chuck it in and it will still stand verticle.

The way I have found drilling blanks is that I always cut them into the tops and bottoms before drilling. I have only ever done 2 part jobbies. I always drill from the middle and make sure that is an acurate center. If the drill does wander it doesn't matter as long as there is anough 'meat' at the outer end, the grain will mate up in the center of the pen/pencil.

When I have drilled on my lathe I have always used my O'Donnel jaws with the smallest set in place. The blank fits easily and the corners sit securely in the gaps between the jaw sections. But it's a real *** having to fit the blank and tighten up the chuck, move the tailstock into position and lock it, with the drill into the blank, stop, undo, remove, wind the tailstock back, fit the next, tighten, start the lathe, pull the tailstock back to the start, wind the tailstock to drill the next hole, etc.. By that time I can have drilled 1/2 dozen pairs without stopping the drill press.

If you would like to see my equally expensive jig for cutting the blanks to lenghts then I would be pleased to post it again. Along with the jig i use for doing Celtic knots on pens..