OPJ

Established Member

Hi guys,

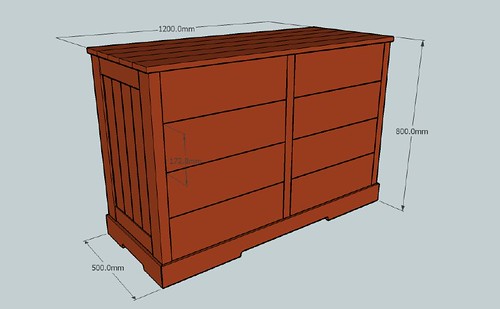

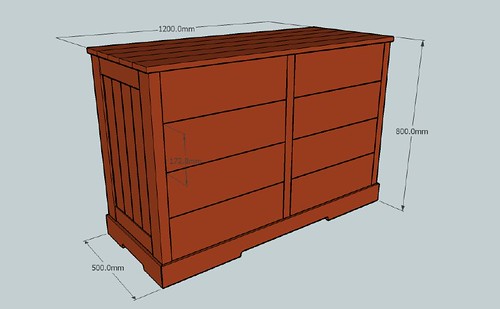

Following the success of the stained-pine Blanket Chest, I've now been asked to look at building a chest of drawers in the same timber and style. Drawer fronts must be inset, not onset, while overlapping the rails but finishing flush (1mm back) with the stiles. It must also be to the same dimensions and same finish. Back panel, at this stage, is a sheet (or two) of 6mm MDF.

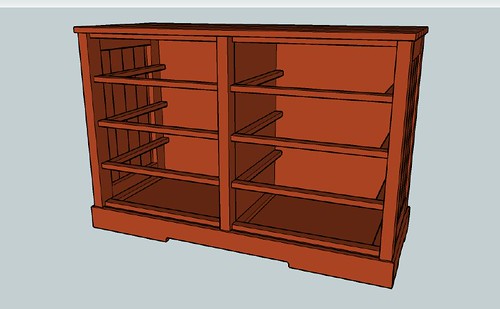

Initially, they were looking for a two-by-three, six-drawer configuration but, after my initial SketchUp scrawlings, we agreed on an eight-drawer design as below:

I'm happy with the base, plinth and I'll deal with the drawers later (probably hand-cut dovetails). I'm still scratching my head over some of the constructional details of the main carcase.

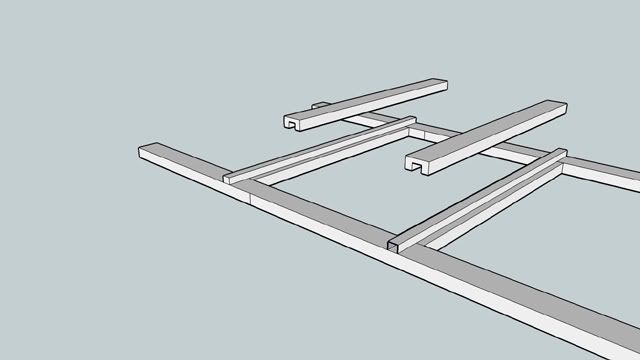

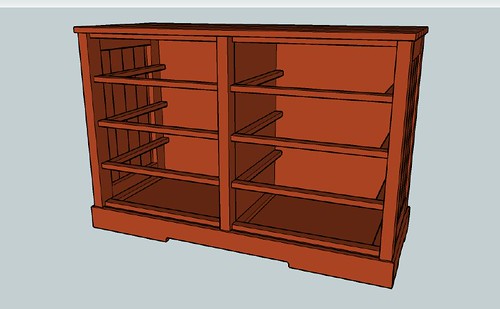

I'm hoping to use wooden runners, kickers and drawer rails. As shown, this is a frame and panel construction at both ends, with a central divider (veneered MDF at this point). I can't see how this will work without beefing up the thickness of the stiles (as I've done in the drawing, 38mm thick instead of 19mm). There would be enough material, particularly in the centre, for me to twin-tenon the drawer rails in place.

My biggest concern here is that in beefing up the sections of timber, this is obviously going to cost more money. :roll: As before, we're trying keep the budget fairly low...

So, what would I like to know?

- Frame and panel construction at both ends could create difficulty in fixing the runners. My other thought is to keep the front stiles at 38mm with the rest of the frames at 19mm. Then, I could attach a sheet of 19mm MDF to the inside, which should give me somewhere to fix the runners - what do you think? Can you think of another solution?

- Central dividers are also drawn at 38mm. I was planning to double-up two sheets of 19mm MDF here, to save buying a full sheet of 38mm! I could widen the front lipping to take twin-mortises for the drawer rails. Any other opinions here?

- What do you think about the sizing of the drawer fronts? They're drawn, here, at 172.8mm wide; all equal. I have 691mm between the base and top and have tried working to the Golden Ratio but, I thought the upper drawers looked too narrow... Any other ideas? I don't think I want to fronts to be any wider than they are now. :?

Following the success of the stained-pine Blanket Chest, I've now been asked to look at building a chest of drawers in the same timber and style. Drawer fronts must be inset, not onset, while overlapping the rails but finishing flush (1mm back) with the stiles. It must also be to the same dimensions and same finish. Back panel, at this stage, is a sheet (or two) of 6mm MDF.

Initially, they were looking for a two-by-three, six-drawer configuration but, after my initial SketchUp scrawlings, we agreed on an eight-drawer design as below:

I'm happy with the base, plinth and I'll deal with the drawers later (probably hand-cut dovetails). I'm still scratching my head over some of the constructional details of the main carcase.

I'm hoping to use wooden runners, kickers and drawer rails. As shown, this is a frame and panel construction at both ends, with a central divider (veneered MDF at this point). I can't see how this will work without beefing up the thickness of the stiles (as I've done in the drawing, 38mm thick instead of 19mm). There would be enough material, particularly in the centre, for me to twin-tenon the drawer rails in place.

My biggest concern here is that in beefing up the sections of timber, this is obviously going to cost more money. :roll: As before, we're trying keep the budget fairly low...

So, what would I like to know?

- Frame and panel construction at both ends could create difficulty in fixing the runners. My other thought is to keep the front stiles at 38mm with the rest of the frames at 19mm. Then, I could attach a sheet of 19mm MDF to the inside, which should give me somewhere to fix the runners - what do you think? Can you think of another solution?

- Central dividers are also drawn at 38mm. I was planning to double-up two sheets of 19mm MDF here, to save buying a full sheet of 38mm! I could widen the front lipping to take twin-mortises for the drawer rails. Any other opinions here?

- What do you think about the sizing of the drawer fronts? They're drawn, here, at 172.8mm wide; all equal. I have 691mm between the base and top and have tried working to the Golden Ratio but, I thought the upper drawers looked too narrow... Any other ideas? I don't think I want to fronts to be any wider than they are now. :?