Jacob

What goes around comes around.

Someone asked what I was up to 8)

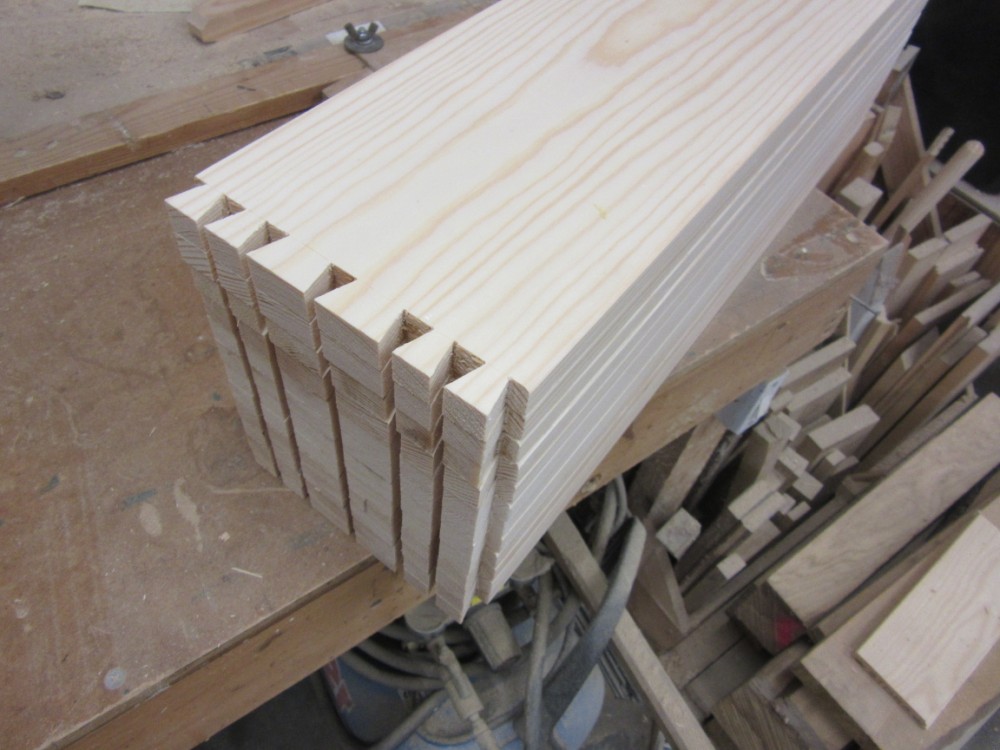

Just doing a prototype. Recycled softwood. 4 narrow but long drawers in a chest. More of an exercise in DTs than anything and I haven't done many for a long time. It'll do for turning chisels and I'll make some better ones with better wood.

Design based on existing old chest.

DTs: Deep cutting gauge lines to work to - deeper means less likelihood of chisel wedging itself back over the line.

Pin holes laid out with dividers, very quick.

Squared with pencil and/or scribe marks

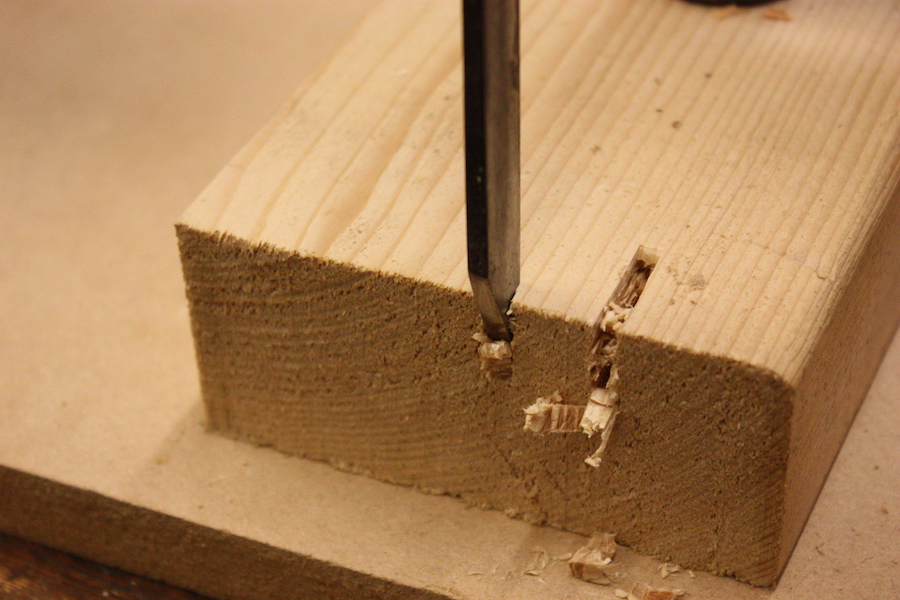

Shallow DT saw cuts started vertical then tilted freehand for the bevels. n.b. essential to have all saw cuts just over the line by as little as possible, to make easy waste removal - no scraping about in corners.

Two or 3 vertical tenon saw cuts in the waste to make it easier to remove. Easier than fiddling with coping saw the modern way.

n.b. Sawing very quick - all done freehand before you'd even finish marking up bevels.

Chiselled out. A lot of them so you work along from one to the other, same stroke on each, no changing chisel, all around one side. Turn over ditto other side. Turn again and next mallet belts are through.

Mark up blind DTs in sides from the bottom piece and the two top rails.

Sawing carefully to the lines here of course, not freehand. Similar systematic chopping - a bit from each, not one at a time.

This all a bit of a novelty for me I've never done so many at the same time.

Then bingo bottom goes straight in to side!! Very pleased - the boards were a bit bendy but they get held in straight.

Now for the other side.

Then the 4 f***g drawers and I'll be good at DTs!

PS it's very interesting how the design I'm copying avoids differential movement stresses in spite of 2ft wide solid boards - the bare carcase as seen here, plus 3 front rails to come, has the grain all going the same way so no prob. But when you get to the runners in housings they go across the grain. Answer - have them loose fitting. Front end loose dry M&T into front rails, back end one screw.

The bottom:

Two top rails

Just doing a prototype. Recycled softwood. 4 narrow but long drawers in a chest. More of an exercise in DTs than anything and I haven't done many for a long time. It'll do for turning chisels and I'll make some better ones with better wood.

Design based on existing old chest.

DTs: Deep cutting gauge lines to work to - deeper means less likelihood of chisel wedging itself back over the line.

Pin holes laid out with dividers, very quick.

Squared with pencil and/or scribe marks

Shallow DT saw cuts started vertical then tilted freehand for the bevels. n.b. essential to have all saw cuts just over the line by as little as possible, to make easy waste removal - no scraping about in corners.

Two or 3 vertical tenon saw cuts in the waste to make it easier to remove. Easier than fiddling with coping saw the modern way.

n.b. Sawing very quick - all done freehand before you'd even finish marking up bevels.

Chiselled out. A lot of them so you work along from one to the other, same stroke on each, no changing chisel, all around one side. Turn over ditto other side. Turn again and next mallet belts are through.

Mark up blind DTs in sides from the bottom piece and the two top rails.

Sawing carefully to the lines here of course, not freehand. Similar systematic chopping - a bit from each, not one at a time.

This all a bit of a novelty for me I've never done so many at the same time.

Then bingo bottom goes straight in to side!! Very pleased - the boards were a bit bendy but they get held in straight.

Now for the other side.

Then the 4 f***g drawers and I'll be good at DTs!

PS it's very interesting how the design I'm copying avoids differential movement stresses in spite of 2ft wide solid boards - the bare carcase as seen here, plus 3 front rails to come, has the grain all going the same way so no prob. But when you get to the runners in housings they go across the grain. Answer - have them loose fitting. Front end loose dry M&T into front rails, back end one screw.

The bottom:

Two top rails