Right then, here goes nothing!

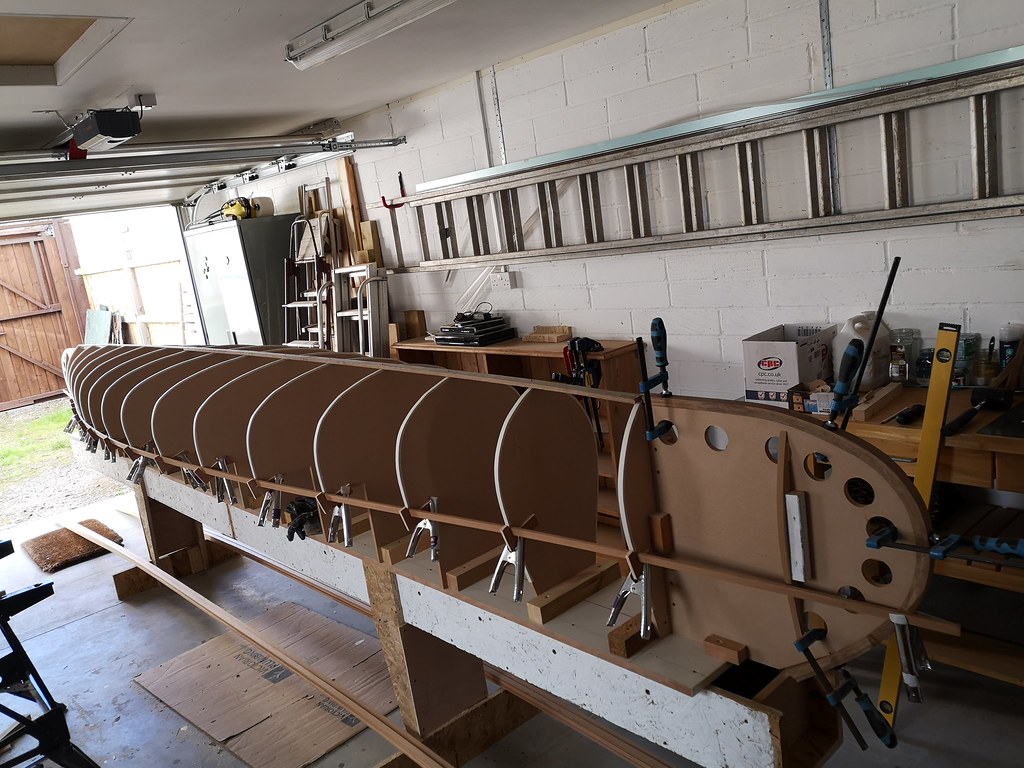

I'd been watching a lot of wooden boat building videos on Youtube (damn that algorithm) and despite not having any connection to the world of seafaring whatsoever, I soon found myself measuring up my driveway to see how big of a Bristol pilot cutter I could fit on it. When my sensible side (her name is Lisa) kicked in, I decided I should start a little smaller and work my way up, and a canoe was about as small as I could picture.

My dad seemed interested in getting involved too, and I was very interested in his 21 foot long, mostly empty garage which would stop me having to entirely devote my workshop to the project for the forseeable.

Books were bought, the best by far being "Canoecraft" and we decided on a 17ft Redbird 2 person canoe.

The books include something called a table of offsets which in theory contains all the information you need to make the sectional templates (called stations) which you build the canoe around. The table however is quite mystifying to the uninitiated and most people will shell out around £100 for a set of full sized plans and instructions.

Now me being stubborn (and cheap) and an occasional engineer, I decided that the table was all I needed and if you could, in theory, make a canoe from this confusing mess of numbers, then I would.

There were a fair few headscratching moments, everything is in boatbuilding code, with stations, stems, sheers and buttock lines, not to mention the whole thing is written out in feet, inches and eighths (with a + denoting a sixteenth) whereas I live strictly in the metric world. (just dont ask me how tall I am, or what I weigh)

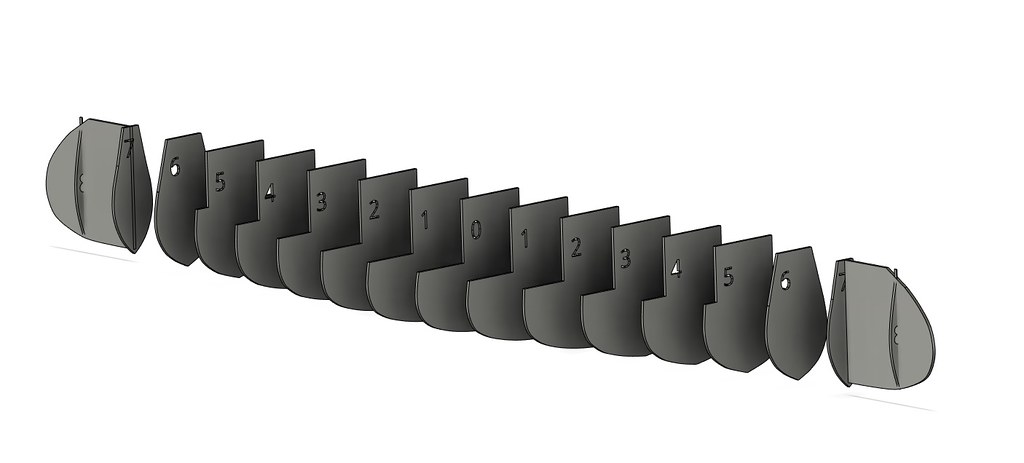

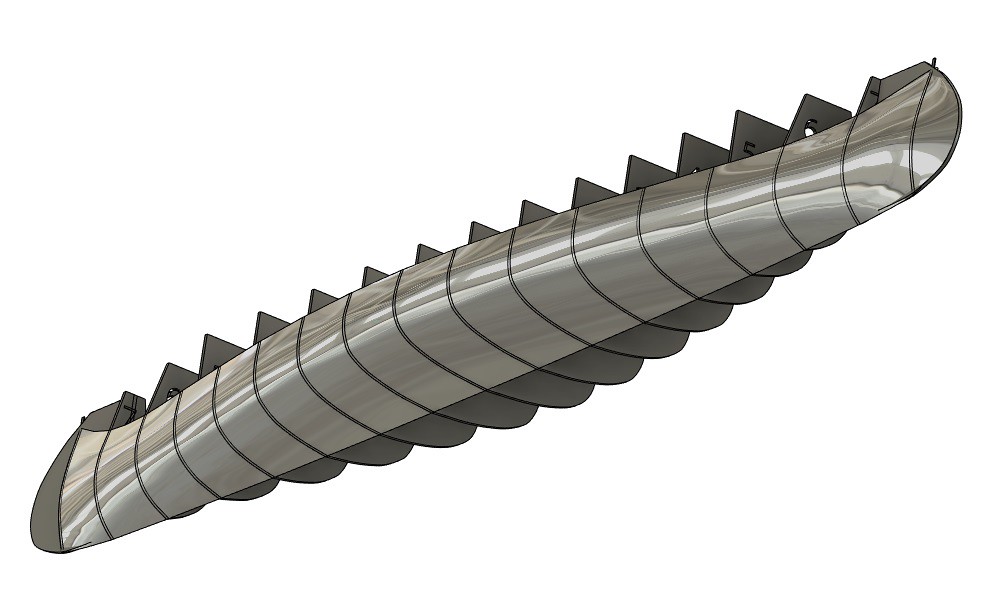

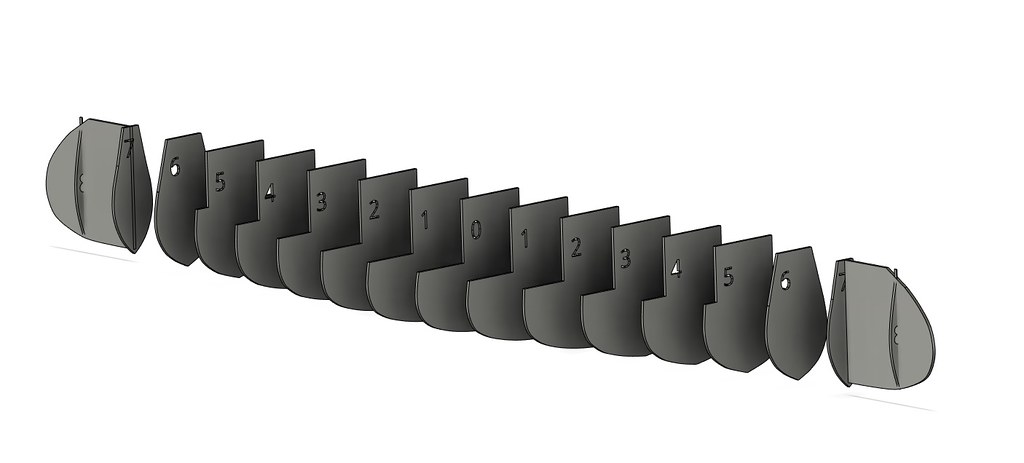

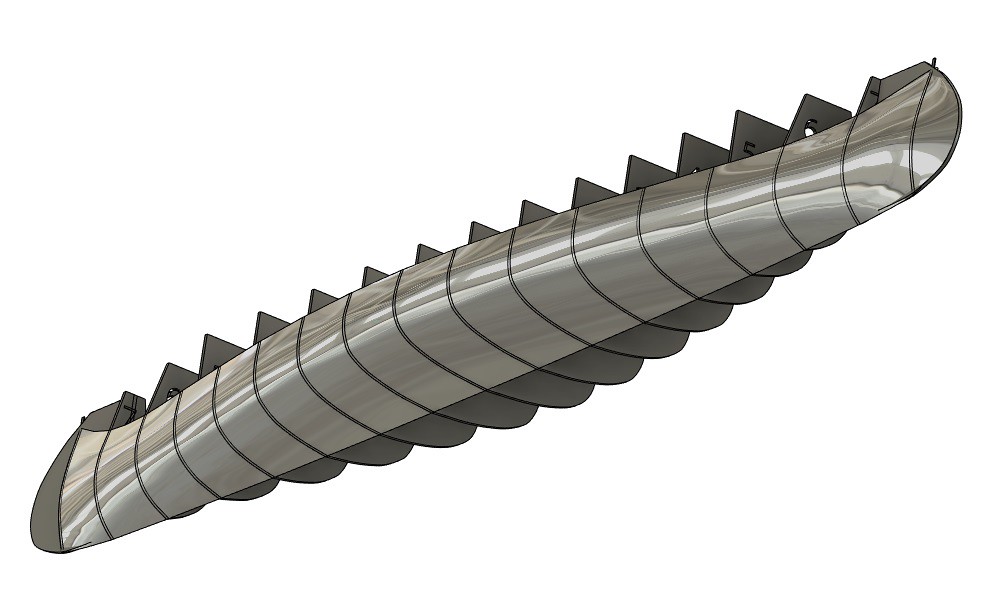

I got there eventually though, and with the aid of some computer wizardry, I managed to loft out all the stations

Putting this into CAD had another advantage, I was able to surface the stations to get a better look at what the canoe would look like and more importantly, to see if I had messed up with the table of offsets and put a big wibbly line down the side of the hull. This actually saved us from a big headache as I had entered the location of the keel wrong on one station, something we would not have spotted until we were laying strips on the canoe and it would have been too late.

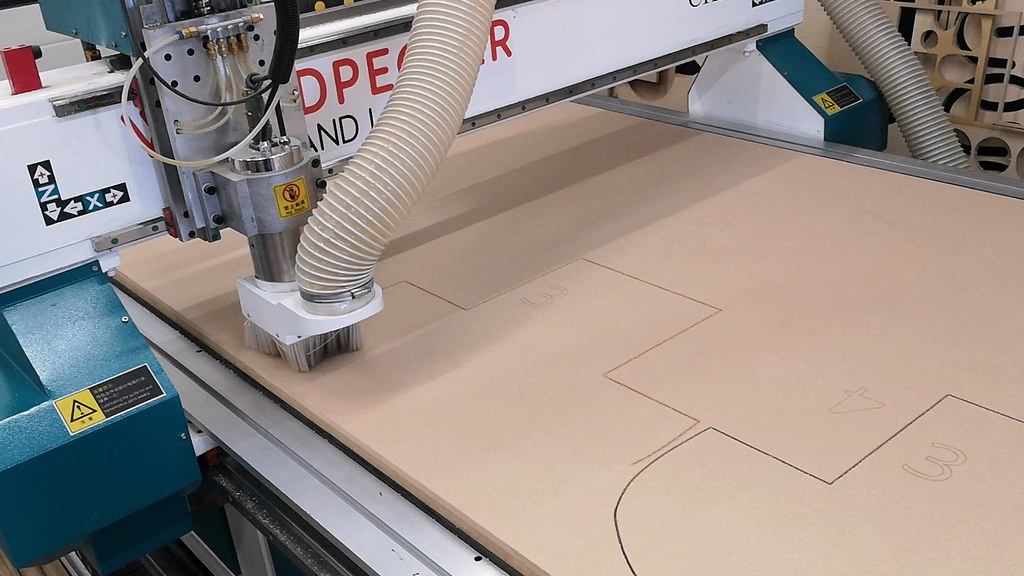

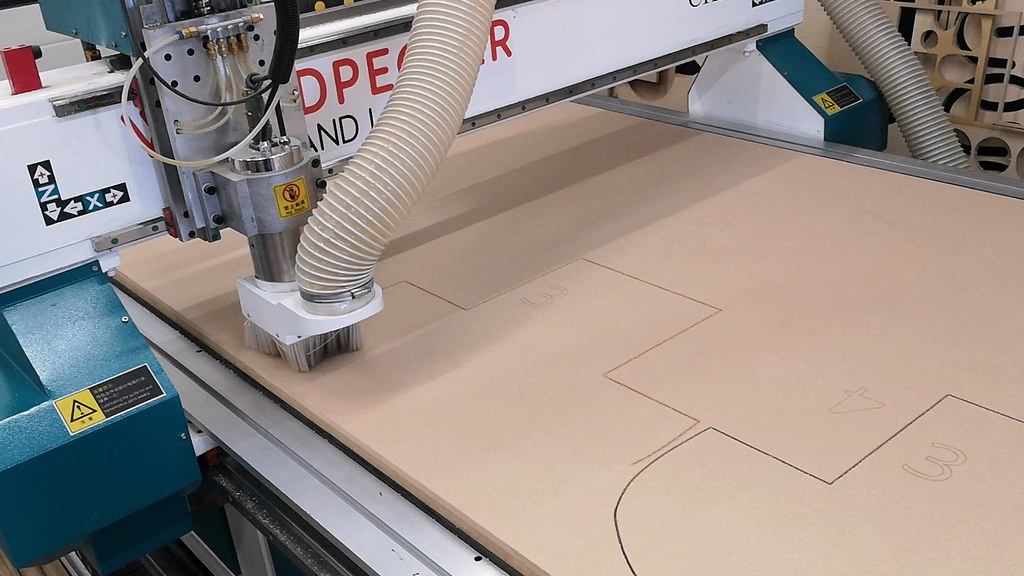

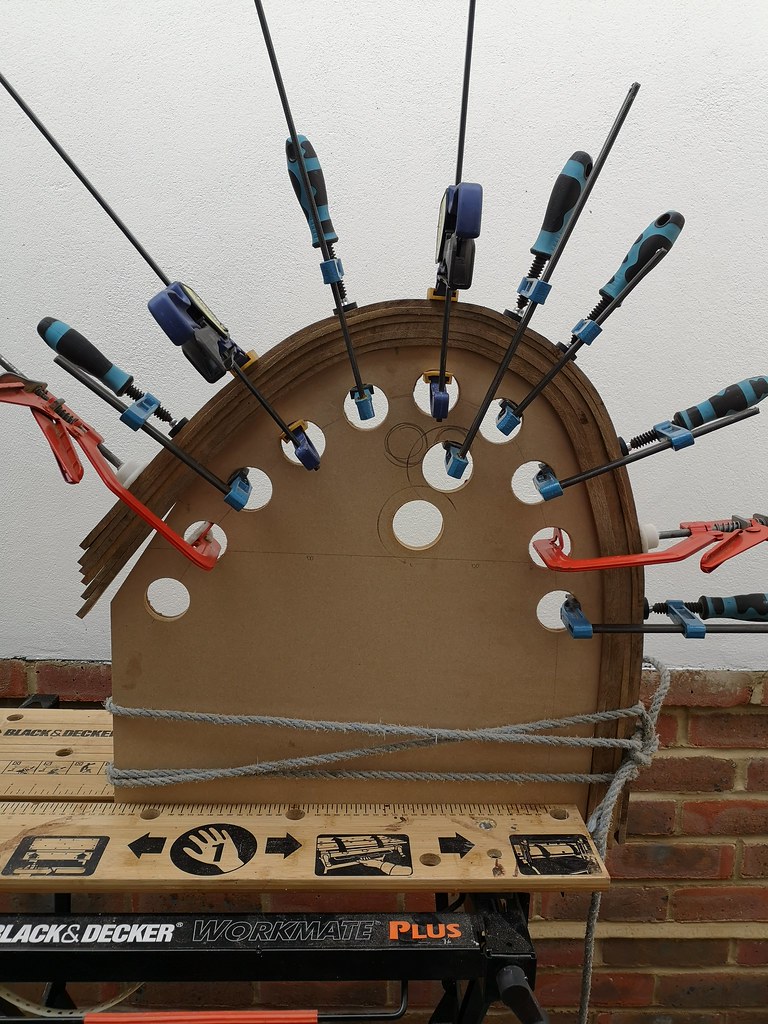

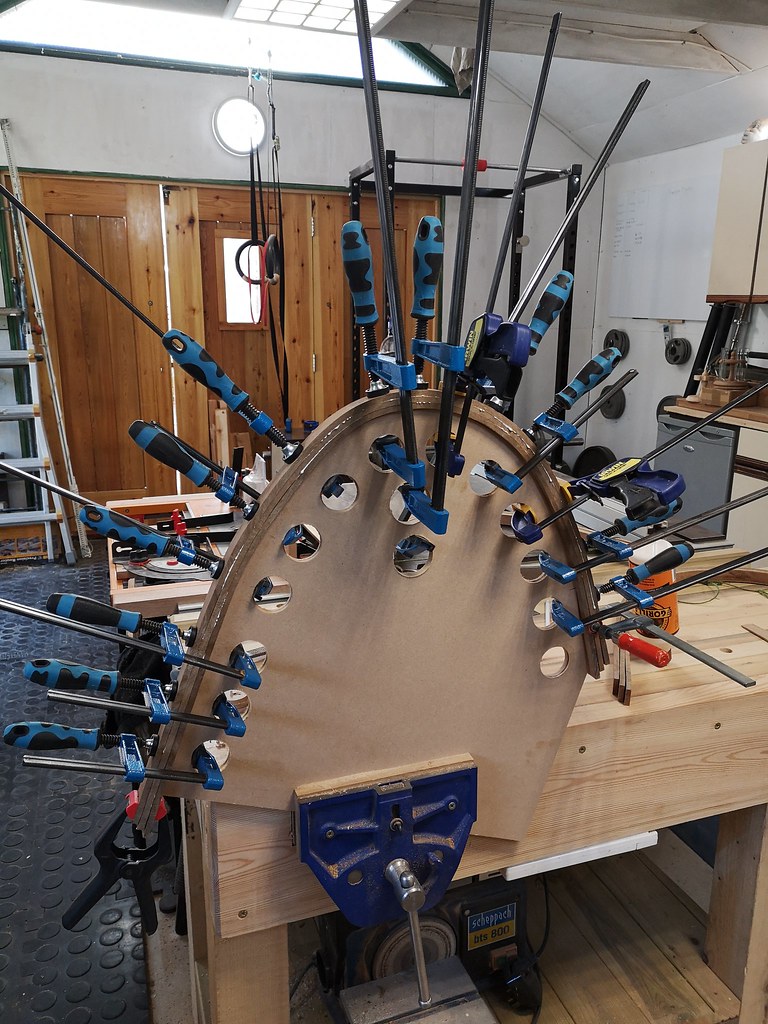

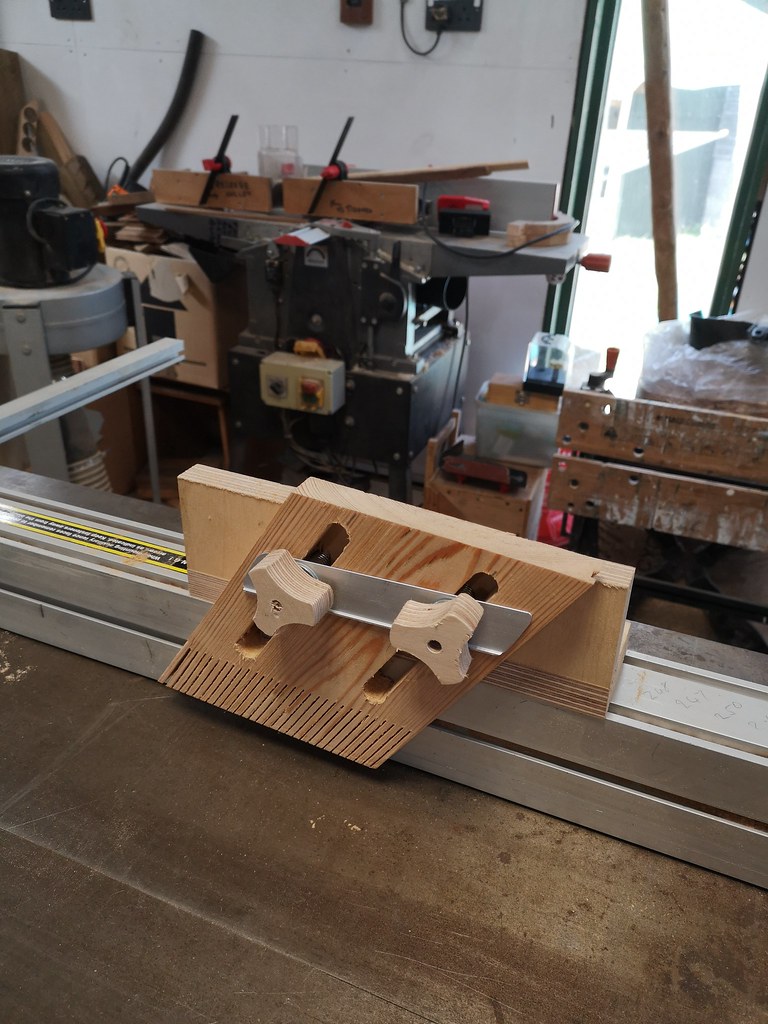

Once I was happy with the stations, I used some of the money I saved on buying plans to get them CNC profile cut, it seemed like a hugely time consuming job that was wide open to errors, and the kind of thing that a flatbed CNC excels at. Thanks to the guys at Woodpecker CNC and Laser, a small local company who offered a great, fast service

CNC and Laser cutting by WoodpeckerCNC on Etsy