Sorry for coming to this message late! Been just too darn busy.

This is the main part of the advice I gave Colin.

***************************************

Slight, even bends are most often from the steel/brass backs coming down onto the saw plate at the toe. This forces the saw plate at the toe to try and move back towards the heel of the saw, creating a bow in the blade.

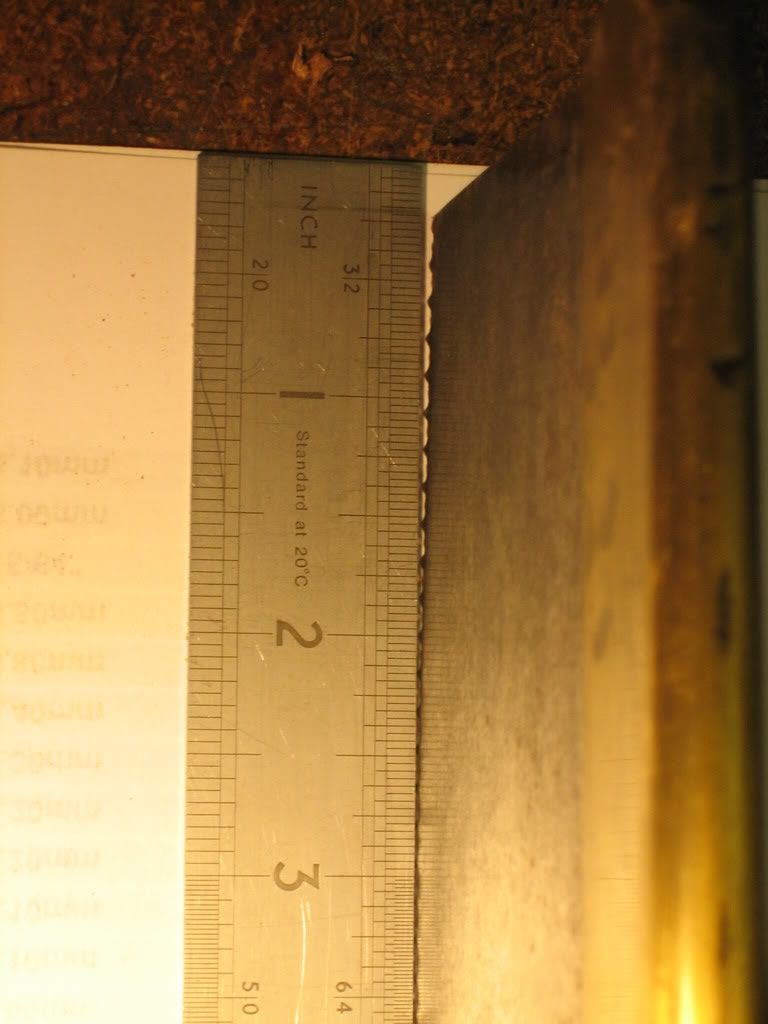

I usually start out by placing two fairly flat boards of equal width and longer than the saw upright in my bench's vise, placing the saw blade between them and clamping tight. The back should be a few mm above the boards. Just enough to get the tip of a flat bladed screwdriver against the saw blade and below the back.

Then I carefully pry the back up beginning at the mid point or a little closer to the toe than the middle and then, split the distance to the toe, and then at the toe. Each time just a nudge, but more each time.

After reaching the toe, I relax the vise, look at the blade and if there is an improvement, but it's not all the way straight, I reclamp and do it again. Usually this is all it takes.

Let me know if this works for you. Do be careful about the screwdriver slipping off as it will scratch the back.

***************************************

On your saw, I would simply use it as is unless it caused a miscut--but I would always try it first.

Yours curves away at a mostly unused portion of the blade, the heel. By knocking up the back a little in the middle and then a little more on the way to the toe, it is possible it will tension the blade and make it straight.

It is also possible that because it is under the handle, it is actually the slot in the handle which is causing it to bend away. It can also be that this portion is slightly bent. Removing the blade and back form the saw would determine that. If once removed, it is still bent as in the photo, you can gently bend it back. If you do this, place the heel of the blade on your bench or another firm surface with the blade at the toe off the bench.

With your hands over the back and onto the blade, thumbs on the side it needs to bend towards, gently bend that back portion by pressing down. Check it again. If needed, apply more pressure each time until it is mostly straight, checking after each attempt.

But do the above only if once removed the blade is still bent. If it is in the handle you run the risk of cracking the handle. Also only do this after attempting to straighten the blade by pushing the back up as above.

If needed, I can take some pictures tonight of doing this.

Take care, Mike