Lonsdale73

Established Member

It's about four years since I started getting into woodwork. I think I've said before that I'm a photographer and the original idea was to create my own mouldings for photo frames.

Early on in my woodworking adventure, those dark days afore I found forums and the endless hours of woodworking porn on youtube, I had a very special client with a very special birthday coming up and I wanted to combine my interests to produce something a bit nice to recognise their milestone and reward their ongoing support. Hitherto, I'd worked almost exclusively from whatever they had stocked at my local B&Q which wasn't much! I did regularly pass somewhere that on closer inspection tuned out to be a timber merchant. So on one trip, I made a point of calling in by. It was about 4pm and I was greeted with "We close at half-past!". I explained the situation and said I was looking for some thinnish timber (approx 6-9mm), something a bit nicer than softwood, from which I could produce a nice box-cum-photo frame type thingy.

"I've got this" he said although he wasn't quite sure exactly what "this" actually was. One thing even my untrained eye could tell was it was significantly thicker than 6-9mm! "No problem," he assured me, "I can have it cut in half for you then you'll have twice as much to work with."

It measured about 1m long and he wanted £20 for it. That seemed rather a lot for one smallish piece of wood but then I was only able to compare with the limited offerings so I accepted. He took it off to slice it in half(ish) and I took i back to my fledgling work shop. This is what I found:

What was I supposed to do with that? It was a thoroughly disappointing experience and I've been back once - more out of desperation - and things didn't look a whole lot better. Wasn't even a soul about, good job I'm not the light-fingered type.

I didn't realise I still had this bit. I'd tried salvaging the other piece by sanding it down; it killed my old Bosch sander and made a mockery of a Ryobi One+ 'mouse' sander that I think came free with my drill and I think the piece was ultimately sacrificed to the gods of wood.

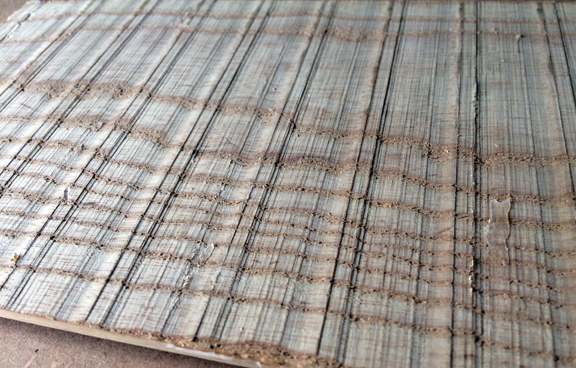

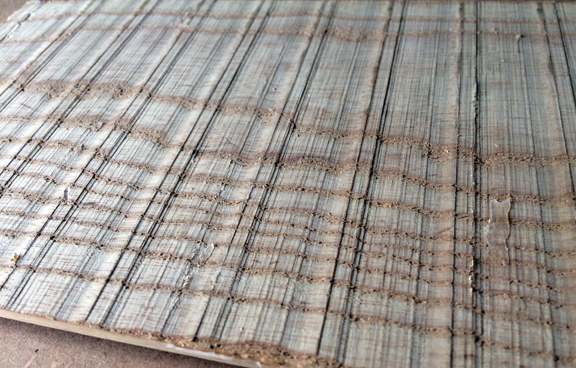

Anyway, I took delivery of a Triton TPT125 Thicknesser today and figured this might as well be used to test it out. It was already a bit too thin for the Triton's minimum thickness so I hot-melt glued it to a length of 18mm MDF to raise it up a bit and this is what I got:

Still not perfect, you can still see some rippling in it but I didn't want to take it any thinner to be left with a sheet of papyrus.

Oh yes, and the point of this post, something that occurred to me earlier and somehow seems common sense but thought I'd ask: Should you ALWAYS plane / thickness with the grain?

Early on in my woodworking adventure, those dark days afore I found forums and the endless hours of woodworking porn on youtube, I had a very special client with a very special birthday coming up and I wanted to combine my interests to produce something a bit nice to recognise their milestone and reward their ongoing support. Hitherto, I'd worked almost exclusively from whatever they had stocked at my local B&Q which wasn't much! I did regularly pass somewhere that on closer inspection tuned out to be a timber merchant. So on one trip, I made a point of calling in by. It was about 4pm and I was greeted with "We close at half-past!". I explained the situation and said I was looking for some thinnish timber (approx 6-9mm), something a bit nicer than softwood, from which I could produce a nice box-cum-photo frame type thingy.

"I've got this" he said although he wasn't quite sure exactly what "this" actually was. One thing even my untrained eye could tell was it was significantly thicker than 6-9mm! "No problem," he assured me, "I can have it cut in half for you then you'll have twice as much to work with."

It measured about 1m long and he wanted £20 for it. That seemed rather a lot for one smallish piece of wood but then I was only able to compare with the limited offerings so I accepted. He took it off to slice it in half(ish) and I took i back to my fledgling work shop. This is what I found:

What was I supposed to do with that? It was a thoroughly disappointing experience and I've been back once - more out of desperation - and things didn't look a whole lot better. Wasn't even a soul about, good job I'm not the light-fingered type.

I didn't realise I still had this bit. I'd tried salvaging the other piece by sanding it down; it killed my old Bosch sander and made a mockery of a Ryobi One+ 'mouse' sander that I think came free with my drill and I think the piece was ultimately sacrificed to the gods of wood.

Anyway, I took delivery of a Triton TPT125 Thicknesser today and figured this might as well be used to test it out. It was already a bit too thin for the Triton's minimum thickness so I hot-melt glued it to a length of 18mm MDF to raise it up a bit and this is what I got:

Still not perfect, you can still see some rippling in it but I didn't want to take it any thinner to be left with a sheet of papyrus.

Oh yes, and the point of this post, something that occurred to me earlier and somehow seems common sense but thought I'd ask: Should you ALWAYS plane / thickness with the grain?