I used to make kitchens in a factory. All carcasses made of 15 MFC and they were all just boxes as most of you have said.

I have had to re-enforce many flatpack carcasses as they are just...crap!

Making them for myself, I always used just MDF, screws and glue. (I am not a master craftsman

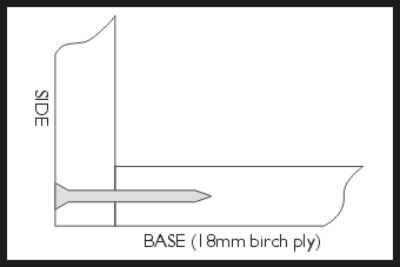

) Simple shelf bearers under both mid and bottom shelves and a 12mm MDF back panel made a very solid if heavy box. The bottom shelf bearers in any carcass greater than 600mm or any appliance housing needs to go all the way to the floor. Unless you are using legs as mentioned. An extra mid bearer/leg is needed on a carcass greater than 600mm.

As we all know it is the doors that make the kitchen and this is where I put most of my time and meagre skills to try and make something half decent.

As long as you are aware of the stress and strains that a carcass will be subjected to, and reenforce as neccessary then we should be OK.

All obvious stuff, but I have seen 1000mm wall units full of tins and crockery fall and smash to the floor(not my work :shock

and appliances drop through the shelving in a tall unit because supposed professional kitchen fitters forgot about stresses.

My latest kitchen is a year old now and looks as good as when I finished it.

I have re oiled the solid wood worktop once. The only thing I would say is that a good solid chopping board is essential to save the worktop. And my wife will tell you that I am far too over protective of any harsh use. As she says, a kitchen, especially certain areas of a worktop will get heavy use so it is inevetable that it will not stay pristine.

Cheers,

Ray.