pren

Established Member

Hey.

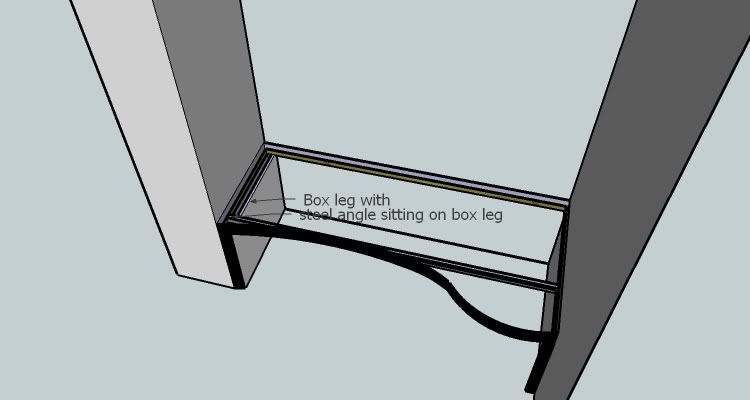

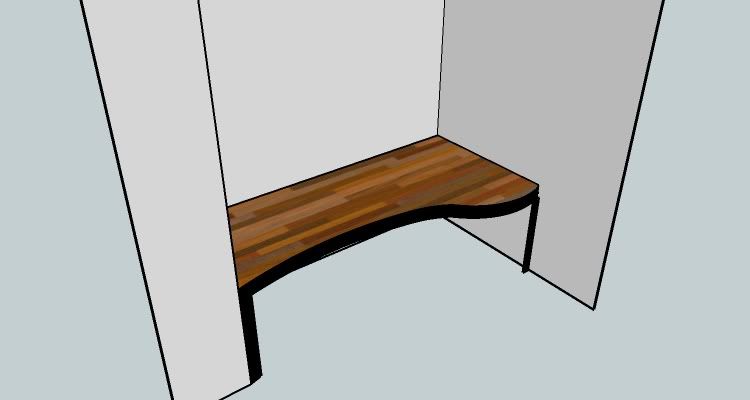

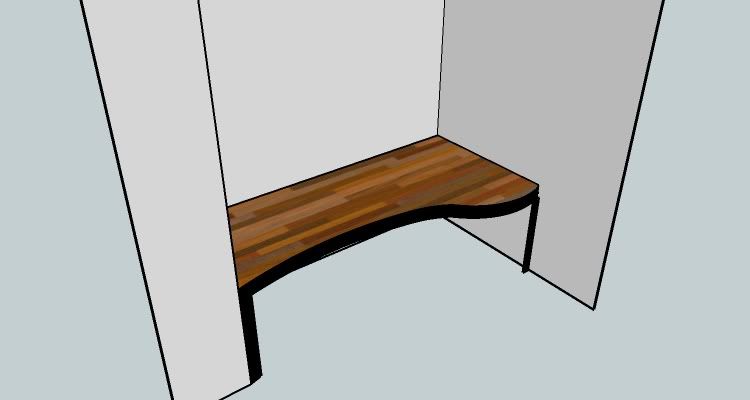

This is a quick sketch of what I was thinking with the steel. I agree that the corner overhang wouldn't be in much danger as it will be supported on the wall end.

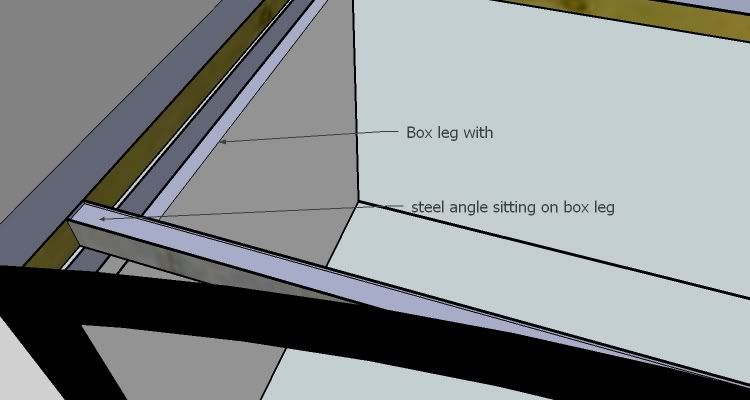

Desk top supported on 3 sides by battens.

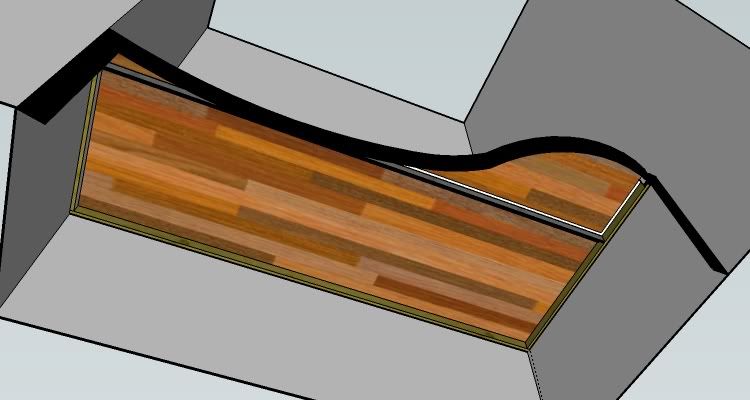

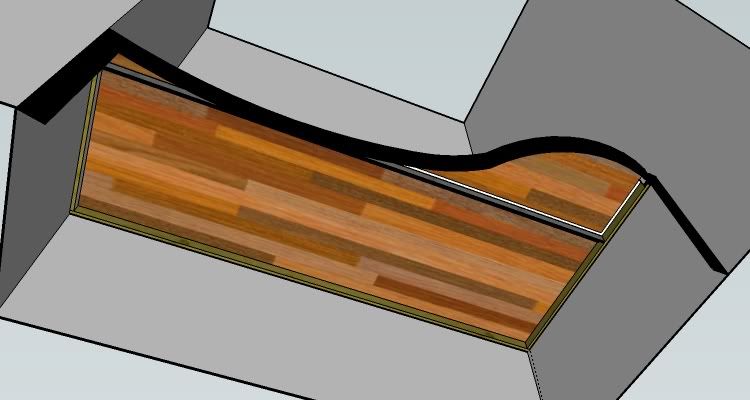

Underside view showing wall battens.

Underside looking towards the front edge. The steel runs straight from wall to wall. This means the desk is supported on 4sides.

The front edge can be made from laminating several layers of 6mm MDF. Not sure as to the size of steel angle. I'd have thought something around 60x60mm might work. Too deep and it'll dig into your thighs.

Hope that helps. 8)

This is a quick sketch of what I was thinking with the steel. I agree that the corner overhang wouldn't be in much danger as it will be supported on the wall end.

Desk top supported on 3 sides by battens.

Underside view showing wall battens.

Underside looking towards the front edge. The steel runs straight from wall to wall. This means the desk is supported on 4sides.

The front edge can be made from laminating several layers of 6mm MDF. Not sure as to the size of steel angle. I'd have thought something around 60x60mm might work. Too deep and it'll dig into your thighs.

Hope that helps. 8)