sawdust maker

Established Member

Well I have been asking questions about how to do this and that in preparation to making a new beakfront Bookcase. And today I went out and blew about £300 on this lot. 8-[ .

6 Cu' of South American Mahogany and one of American White Oak. Got it from John Boddy's. They even planed up the 17" board, that I couldn't manage on my 10" Record P/T.

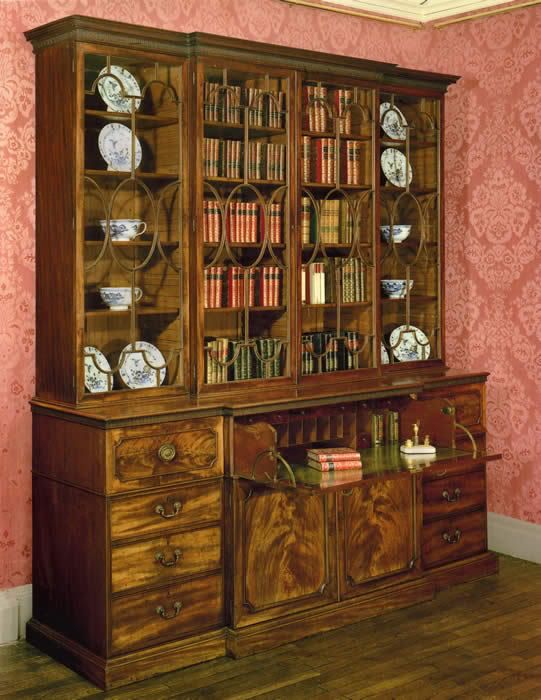

When finished it will stand 6' tall and 6' wide. The base unit will have a protruding section with four drawers, the top two made into a secratiere. The two side base sections will have a drawer above a cupboard. All doors and drawer fronts will be veneered in Mahogany flame veneer and edged with a 1.5mm boxwood string. The top will have four astral glazed doors. I hope to make the astral glazing bars curved to add more interest. On the corners of the base and top unit will have a quarter reeded satinwood collum on am Ebony base and top.

More pictures as things progress, but I think it will be big job and a long post.

6 Cu' of South American Mahogany and one of American White Oak. Got it from John Boddy's. They even planed up the 17" board, that I couldn't manage on my 10" Record P/T.

When finished it will stand 6' tall and 6' wide. The base unit will have a protruding section with four drawers, the top two made into a secratiere. The two side base sections will have a drawer above a cupboard. All doors and drawer fronts will be veneered in Mahogany flame veneer and edged with a 1.5mm boxwood string. The top will have four astral glazed doors. I hope to make the astral glazing bars curved to add more interest. On the corners of the base and top unit will have a quarter reeded satinwood collum on am Ebony base and top.

More pictures as things progress, but I think it will be big job and a long post.