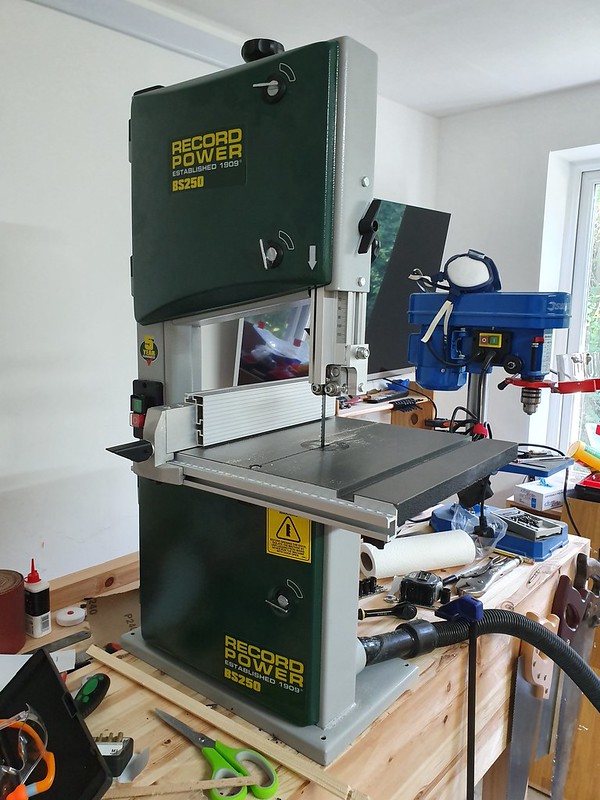

With time to kill at work, I can post some photos at last. Very happy with this, I have to say.

So off the top, it's just over double the weight of the Titan at a respectable 30.3KG. That alone means it feels better and, at "just" £221 instead of the usual £260, it does feel like more than just double the price over the £110 Titan.

Metal abounds. Where the titan has plastic doors, plastic guidepost, plastic gearing for the rack and pinion on the guide post etc, the Record is all metal, some steel, some aluminium. Adjusting the guide post up and down feels robust and solid and once locked down, attempting to move the post simply moves the entire machine, unlike the Titan. The wheels have also been balanced with weights rather than drilling. The titan wheels on my sample have about 8 holes drilled in the back side to balance them.

Also we get 3 A4 manuals, 1 in actual English, 1 in German and 1 in I can't remember. Very nice manuals with the only issue being BW printing, so when they show a black blade on a black tyre to illustrate where the teeth should be, you see nothing at all :lol:. Lots of info in there about setup, minimum radius for different types of blade etc.

One issue I had was the guide post not dropping parallel to the blade. So by the time you got from max cut depth to min cut depth, the thrust bearing was so far away as to be useless. This black T bar shown below is secured with 2 bolts and is what needs adjusting to correct the issue. The manual doesn't mention it. The T bar is for aligning the guide post only. When snugged down, the aluminium extrusion used for the guide post registers against the casing, NOT the T bar. This leads to my later issue.

As well as being drunk in that direction which was fiddly but easy to rectify, it is also drunk in lateral movement. At max depth of cut, the guides are further right of the blade, at the min depth of cut the guides are further left of the blade. It isn't much, but it's an annoying enough amount that I'd like to fix it if I can. Thus far, a paper shim in the top of the extrusion between it and the case has done a job, but it won't stay in place when lowering the guide post. A better solution needs to be sought as I'd rather not keep putting it back in place every time, or adjusting the guide bearings to compensate.

One annoyance was getting everything ready to go and going to re check the lower bearings. These 2 black shrouds came fitted, but are not mentioned or even pictured in the manual. The one to your right is removed with 2 screws on the side face of the case. Easy. The one on the left? That one you need to remove the table to remove the 2 screws to get at the bearing. An oddity resolved swiftly enough with an advanced electrical twist based void creator. As it should have been in the first place.

At this time all that remains is to square the back of the table with the back of the blade. Everything else is spot on and has remained so. The guides have lots of adjustment in all required directions so you'd not be limited in that regard, and everything being metal means it all stays where you put it.

The mitre fence is, predictably, loose in its slot and not particularly rigid even when done up. Finding something 3rd party that will fit in that small slot will prove difficult at best. No idea how much use it would get anyway, so we'll see how I go there.

The fence is an odd one. One thing I can say is that when its locked down, it's staying there. It is comprised of a main fence and an aluminium extrusion that can be flipped around for low profile support. It's secured with 2 thumb wheels on the back of the main fence, but it's quite thin aluminium so it will bend when tightening up with not much pressure. Additionally and probably most importantly, there is no way of squaring it up on the fence itself. The only option is to shim the fence guide bar attached to the front of the table. I'll see how I get on with it.

The construction feels good, no sharp bits looking to remove a layer of flesh, all painted up nicely and adding to the feeling that you actually bought a tool worth half a damn. Considering how high the price can run on larger bandsaws, That feels like a bit of a feat, IMO.

I've barely managed 5 cuts with it yet, however with several more weeks off off work starting on Monday, hopefully I can get started using it for the jobs I have prepared. I also want to pick up a couple of blades.