jimi43

Established Member

Cheers for the tips GP....I have some Liberon sticks and some waxes from that Konig...might try burning some of that into the deep gouges..

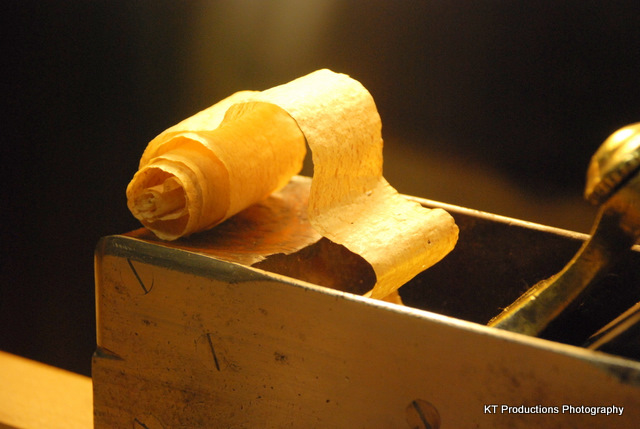

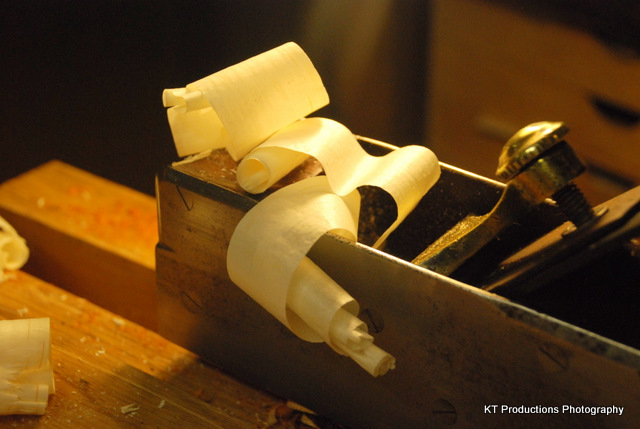

Ok Pete...I bit the bullet with that left over piece of O1....my first attempt at a slotted iron....

First to mark it out...

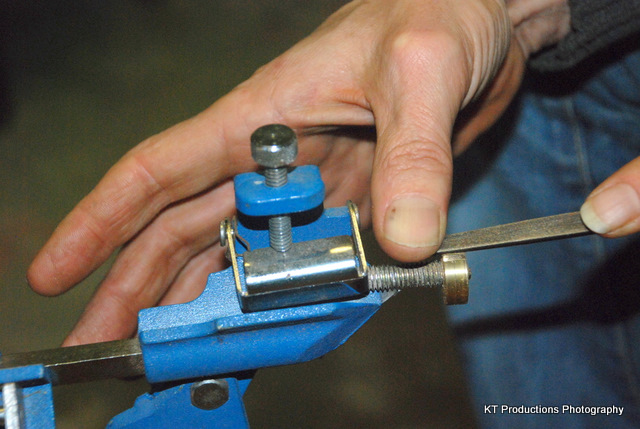

The screw hole was a nightmare as I don't have a metal drill that big and punches would not cut it...(in both senses of the word... :wink: ) but then I remembered I had a series of adjustable reamers...so I started with the biggest drill I had and progressively reamed the rest out...

This was time consuming but the finish is always better with reamers..

Then...how to cut the slot... :?:

:idea: Dremel with cutting discs....!!!! Worked perfectly!

I've a bit of smoothing to do but I am rather pleased with the first attempt.

I put a bevel on it to check the mouth before I fire it...and it is perfect!

So...it's off to fire it tomorrow...and then temper it in the oven...I feel a roast coming on! 8)

I am tempted to round off the top rather than angles but for now...I will keep it fairly traditional...

I think I have made the decision now to keep it...she looks quite nice now she's cleaned up...

More later when I have hardened the iron....

Cheers guys and gals...

Jim

Ok Pete...I bit the bullet with that left over piece of O1....my first attempt at a slotted iron....

First to mark it out...

The screw hole was a nightmare as I don't have a metal drill that big and punches would not cut it...(in both senses of the word... :wink: ) but then I remembered I had a series of adjustable reamers...so I started with the biggest drill I had and progressively reamed the rest out...

This was time consuming but the finish is always better with reamers..

Then...how to cut the slot... :?:

:idea: Dremel with cutting discs....!!!! Worked perfectly!

I've a bit of smoothing to do but I am rather pleased with the first attempt.

I put a bevel on it to check the mouth before I fire it...and it is perfect!

So...it's off to fire it tomorrow...and then temper it in the oven...I feel a roast coming on! 8)

I am tempted to round off the top rather than angles but for now...I will keep it fairly traditional...

I think I have made the decision now to keep it...she looks quite nice now she's cleaned up...

More later when I have hardened the iron....

Cheers guys and gals...

Jim