Maybe I can help by adding another option?

I assume you are a relative beginner. It's probably true to say that sawing perfect tenons is trickier than cutting dovetails, and it's normal when starting out to cut tenons fat and trim them back to the right size. It's obviously not as efficient as fitting straight from the saw but it gets you a good result.

To cut back to size, you can indeed use a chisel, and that's a good approach.

You can also use a plane, but not right into the corner unless it's a more specialised plane than you have, hence your question.

But if you do buy a shoulder plane for this job, I predict that you won't use it much, as you get better with the saw anyway.

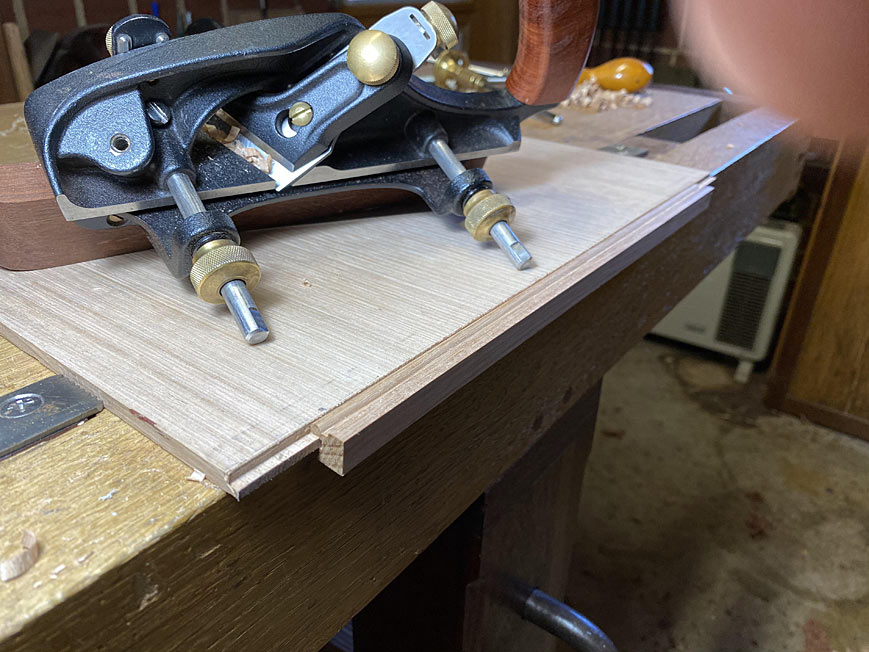

So I suggest you buy a router. I know this would be easier advice to follow if the secondhand price hadn't gone up so much lately, but that has happened because YouTube woodworkers such as Paul Sellers have majored on demonstrating what was in Robert Wearing's books, and shown people that a router is an easy tool to use to do this job. You can reference off a second piece of wood of the same thickness as your workpiece and trim down a few thou at a time, ending with a perfectly flat, true surface.

And you'll also have a tool which opens up the possibility of cuts that are harder to do without one, such as accurate housings and rebates, through or stopped.

Veritas make a very attractive model (if you can find it in stock) and the price is apparently not far off what good used Stanley 71s are going for. Or if you can get or make a cutter, build your own.

Even MikeG has seen the need for one!