It looks like my display cabinet project is going to have to take a back seat for the moment, or be completed at an even slower pace (if that is possible). The house is still being refurbished/decorated which is what I have been up to recently, and now I need to design and build some bifold sliding doors to fill a large opening between two rooms. Mrs O would like them made in oak (solid). That's fine by me.

But having never made any bifolds before I think I may need some pointers/help...

Overall the opening is 2170mm wide by 2030mm high.

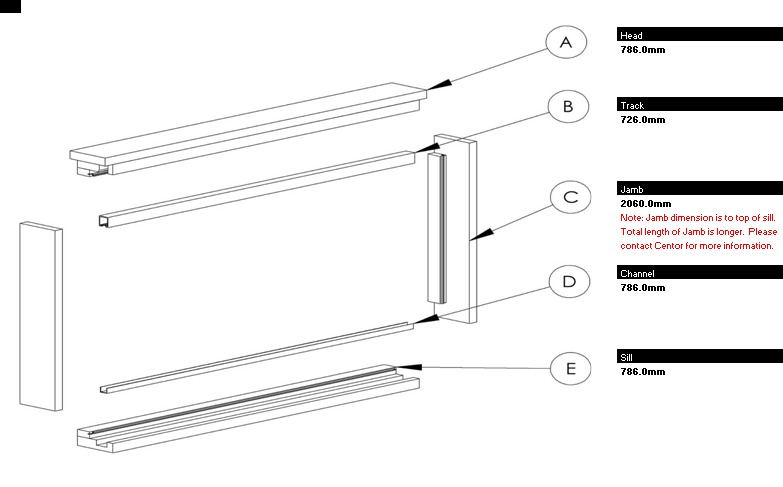

I have decided to use a 25mm thick by ~150mm wide oak square outer frame into which a further door hanging frame is attached with an upper runner & doors. The door hanging frame will be about 35x50mm cross section. The outer frame is needed for aesthetics and to cover up what is a large slot in the floor, 150mm wide, which housed the old step for what was the original french doors which used to open into the garden before the extension room was built.

There will be 4 doors altogether, 2 on each side with a central opening, each pair of doors making the bifolds.

This means each door will be ~470mm wide, so each pair will be ~940mm wide when closed.

The style will be shaker, simple stiles & rails, with as yet undecided number of rails to split the glass into smaller pieces.

I have no idea at the mo how heavy each pair of doors will be, need to make some calcs...

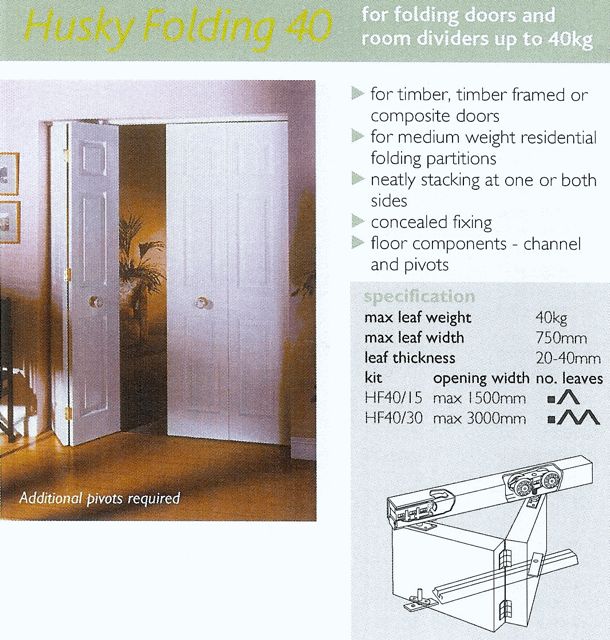

But my main concern is what kind of glide or roller rail system I need and this will be in some way determined by the weight of each pair of doors. I would like only a rail at the top, none at the bottom.

I have tried searching for such rail systems for bifolds but there are so many and some seem to spec what thickness of door you should use with them, usually not equal to 35mm (standard internal door thickness).

I figured that I would just make them the same thickness as standard doors (35mm), but maybe this is not needed?

Has anyone made any bifolds before and able to advise?

If so, where did you get your rail system from?

What hinges did you use?

Hope someone can help?

cheers

Steve

But having never made any bifolds before I think I may need some pointers/help...

Overall the opening is 2170mm wide by 2030mm high.

I have decided to use a 25mm thick by ~150mm wide oak square outer frame into which a further door hanging frame is attached with an upper runner & doors. The door hanging frame will be about 35x50mm cross section. The outer frame is needed for aesthetics and to cover up what is a large slot in the floor, 150mm wide, which housed the old step for what was the original french doors which used to open into the garden before the extension room was built.

There will be 4 doors altogether, 2 on each side with a central opening, each pair of doors making the bifolds.

This means each door will be ~470mm wide, so each pair will be ~940mm wide when closed.

The style will be shaker, simple stiles & rails, with as yet undecided number of rails to split the glass into smaller pieces.

I have no idea at the mo how heavy each pair of doors will be, need to make some calcs...

But my main concern is what kind of glide or roller rail system I need and this will be in some way determined by the weight of each pair of doors. I would like only a rail at the top, none at the bottom.

I have tried searching for such rail systems for bifolds but there are so many and some seem to spec what thickness of door you should use with them, usually not equal to 35mm (standard internal door thickness).

I figured that I would just make them the same thickness as standard doors (35mm), but maybe this is not needed?

Has anyone made any bifolds before and able to advise?

If so, where did you get your rail system from?

What hinges did you use?

Hope someone can help?

cheers

Steve