Moonsafari69

Established Member

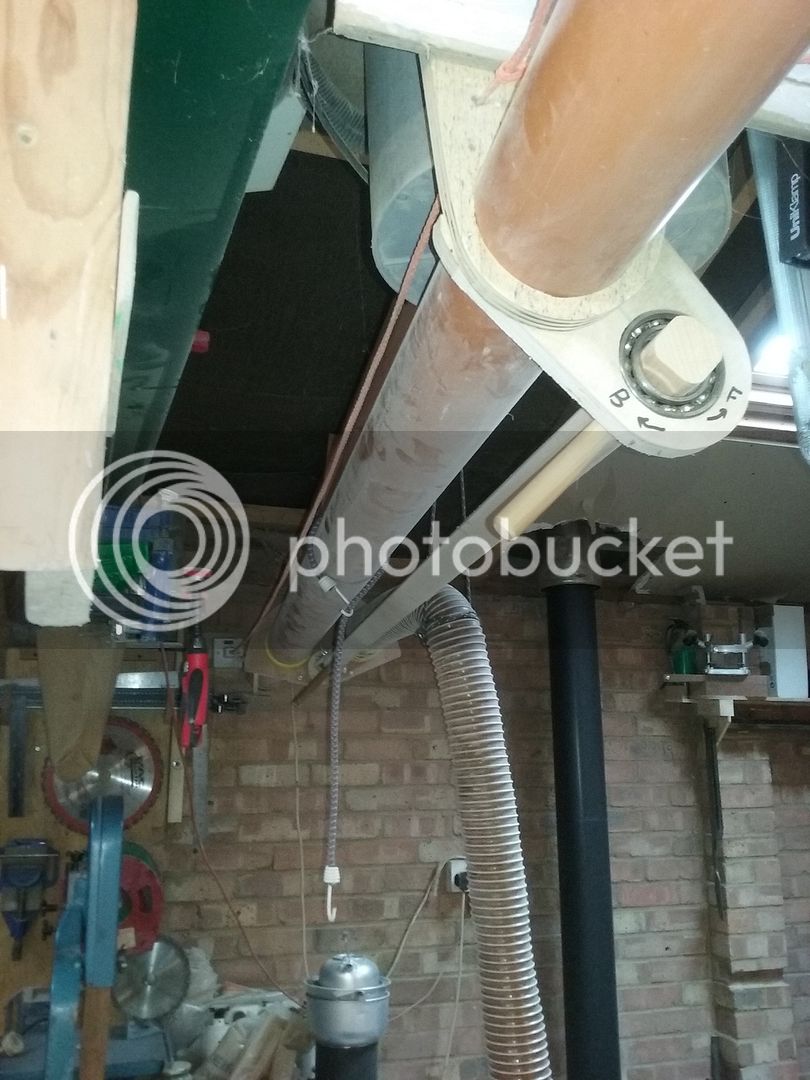

I've always had problems with blast gates fitted to my 2 1/2" ducting. I used the black ABS type for a while but eventually, no matter how clean I kept them, they would collect sawdust inside the gap which meant there was always leakage. To stop the inevitable loss of suction about a year ago I changed my ducting round so that I had my three main duct routes ending up in the same spot quite close to my dust collector.

The solution is really simple, and completely eliminates the blast gate issues. I have one small length of 2 1/2" flex hose fitted secure at the end closest to the dust collector. The other end simply gets moved from one pipe to another depending on which piece of kit I need it working on. It's likely quicker than swapping over blast gates too. Fitting the 45' bend on the end of each pipe means the flex fits nice and snug and makes for access better too. Maybe this will be of use to someone else.

The solution is really simple, and completely eliminates the blast gate issues. I have one small length of 2 1/2" flex hose fitted secure at the end closest to the dust collector. The other end simply gets moved from one pipe to another depending on which piece of kit I need it working on. It's likely quicker than swapping over blast gates too. Fitting the 45' bend on the end of each pipe means the flex fits nice and snug and makes for access better too. Maybe this will be of use to someone else.