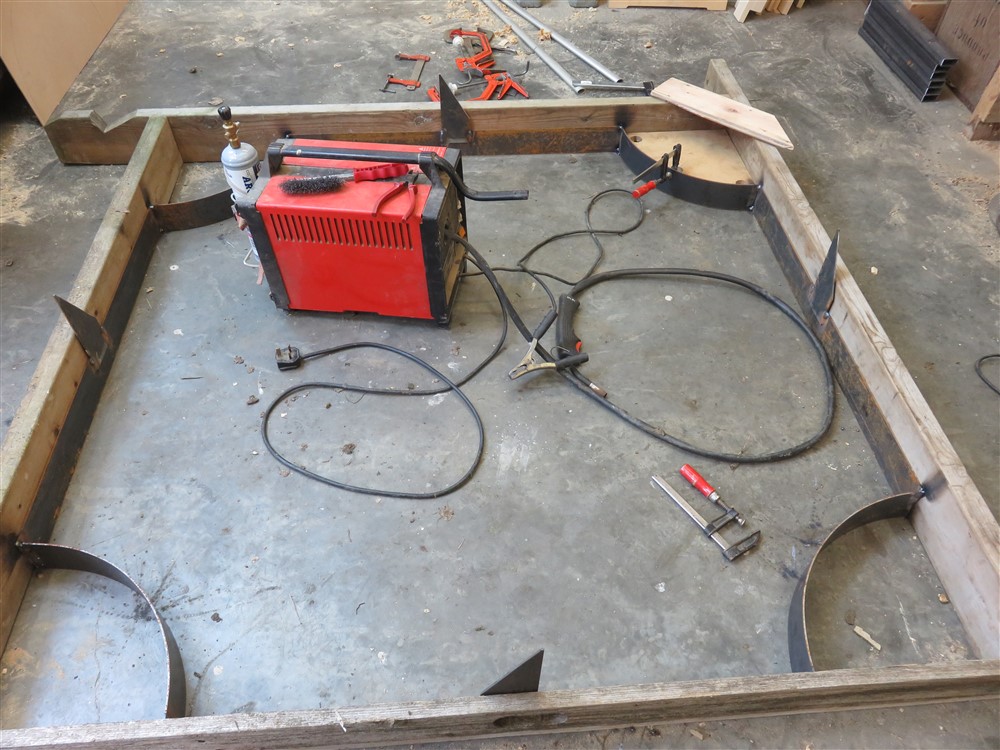

Probably a daft Q MikeG, but here goes anyway. How many times have you put that MS strip through youR jig (shown)?

If "only" once may I suggest that before you do anything else, you do it again to see if the curvature has increased after a 2nd go. If so, try a third time - 3 mm strip in MS is not all that thick but still demands some force to "persuade" it, and not all MS is SO soft!

While softening it with your torch MAY work, if it's only a relatively small one you run some risk of it not heating evenly - therefore "hard" (er) patches along its length.

IF the above 2nd/3rd/another go does get you nearer to the required curvature, then I'd suggest a fairly simple mod to your present (pretty useful-looking IMO) jig, viz:

Replace the block under the long arm with, ideally a ball bearing (or 2, height to suit strip width) mounted on a bolt fixed to a trunnion affair (ply?) on the long arm. The bearing/s will direct the bending force onto a more localised area of the strip to be bent and "should" (maybe!) further increase the curvature of the strip!

Take notice of by how much the extra bend session/s (and the bearing/s?) have tightened the curvature after your 1st go, and if necessary, work out by how much you need to reduce the diameter on the main (circular) former to achieve what you need.

Sorry, not very "scientific" I know, but I THINK that should (maybe!) get you where you need to be - in the end!

(By all means send me a "snottogram" if it doesn't work as above, but I've got a feeling that it just might. ;-)

HTH