A

Anonymous

Guest

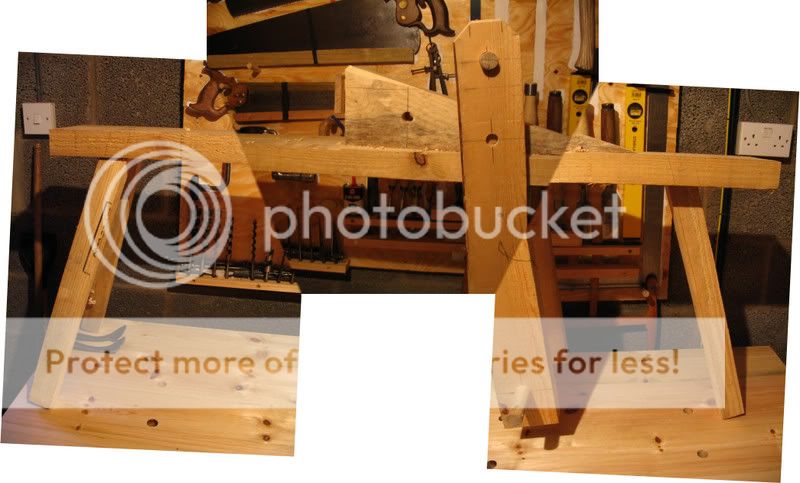

I finished off my bench today. Heres a pic

I was originolly going to use a beech wood screw for the vice but decided to get a metal jobbie from axerminster tool company instead. The holdfast's work like a dram, I was aprehensive I thought I might have wasted £40 if the shape is wrong or theres a design fault :shock: :roll: However, ONE tap with mallet, it did just what it says on the tin and stuck like a limpet. Oh no I thought that might be wedged too tight and be impossible to remove, no worries ONE tap at the back and up it pops just like it syas on the tin. It grips solid as a rock. I am well pleased. I added 4x2's under the bench top to increase the thickness to 4 inch's where the holdfast's go through. Yes theres a nasty chaeck opened up along the front dge, I may well add an oak lip at some point, I'll see how it goes. I also might inset the horizontal vice jaw into the bench apron to make it flush. Again see how it goes. I am going to build one of those german style stands to hold up one end of the board for planing. Seat carvings going to be a lot easier and less fiddly :lol:

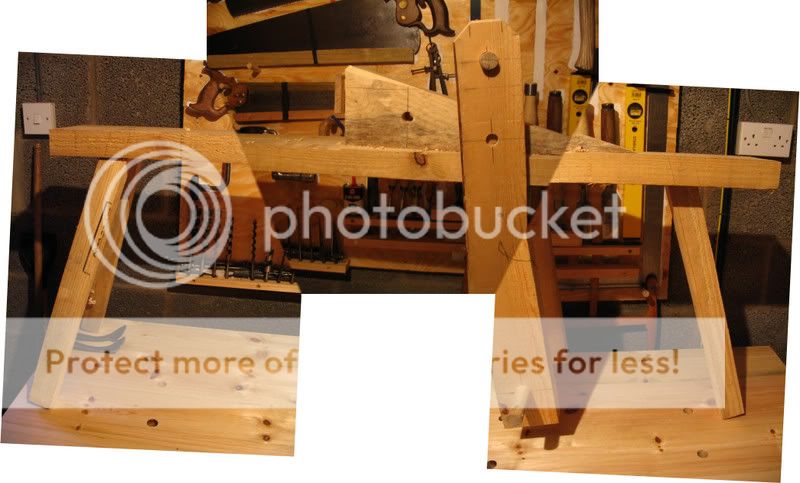

Also I built up a new shaving horse, almost complete apart from levelling the legs. I also gotta make some special slot in jiggies to hold various diameters also one for pegs (large ones) They will drop into holes on the wedge with 2 peg locaters. I got fed up using the post vice to do spindles as Mr Dunbar does, this is faster and more traditionall as well :lol:

Heres a pic

Cheers Jonathan

I was originolly going to use a beech wood screw for the vice but decided to get a metal jobbie from axerminster tool company instead. The holdfast's work like a dram, I was aprehensive I thought I might have wasted £40 if the shape is wrong or theres a design fault :shock: :roll: However, ONE tap with mallet, it did just what it says on the tin and stuck like a limpet. Oh no I thought that might be wedged too tight and be impossible to remove, no worries ONE tap at the back and up it pops just like it syas on the tin. It grips solid as a rock. I am well pleased. I added 4x2's under the bench top to increase the thickness to 4 inch's where the holdfast's go through. Yes theres a nasty chaeck opened up along the front dge, I may well add an oak lip at some point, I'll see how it goes. I also might inset the horizontal vice jaw into the bench apron to make it flush. Again see how it goes. I am going to build one of those german style stands to hold up one end of the board for planing. Seat carvings going to be a lot easier and less fiddly :lol:

Also I built up a new shaving horse, almost complete apart from levelling the legs. I also gotta make some special slot in jiggies to hold various diameters also one for pegs (large ones) They will drop into holes on the wedge with 2 peg locaters. I got fed up using the post vice to do spindles as Mr Dunbar does, this is faster and more traditionall as well :lol:

Heres a pic

Cheers Jonathan