devonwoody

Established Member

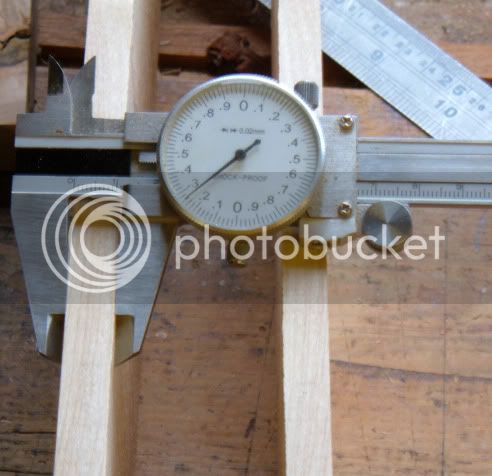

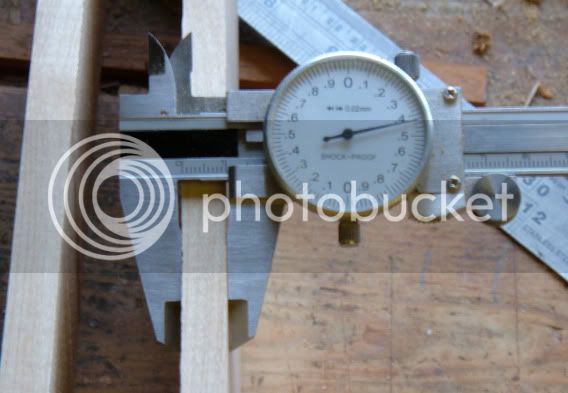

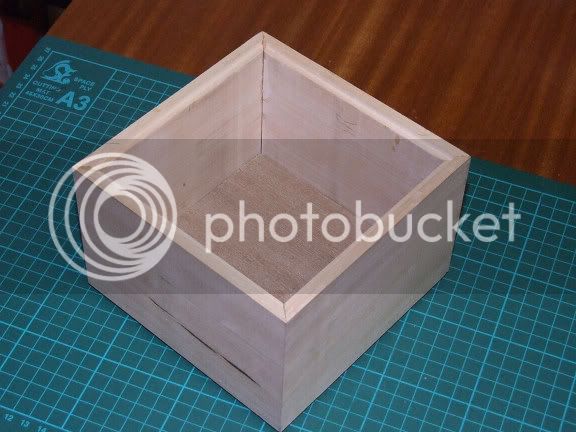

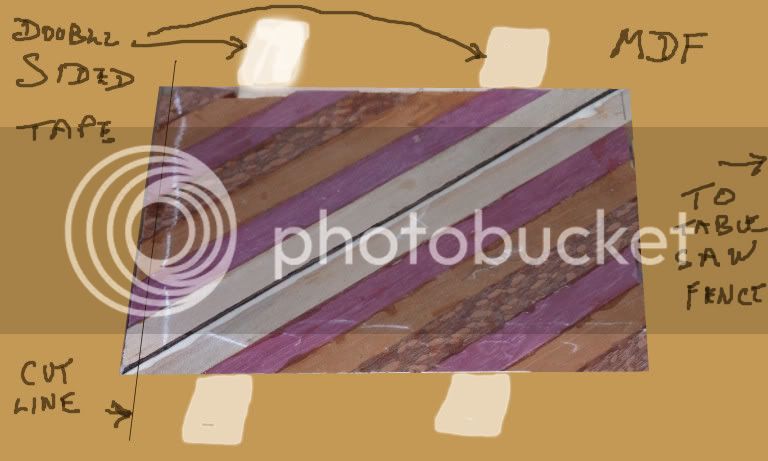

Started preparing sone sycamore for a box

Decided to snap a piece of waste timber after putting through the table saw and the sharp end ripped my finger open.

So will be a few days before I start again, its right on the index finger joint.

Decided to snap a piece of waste timber after putting through the table saw and the sharp end ripped my finger open.

So will be a few days before I start again, its right on the index finger joint.