J-G

Established Member

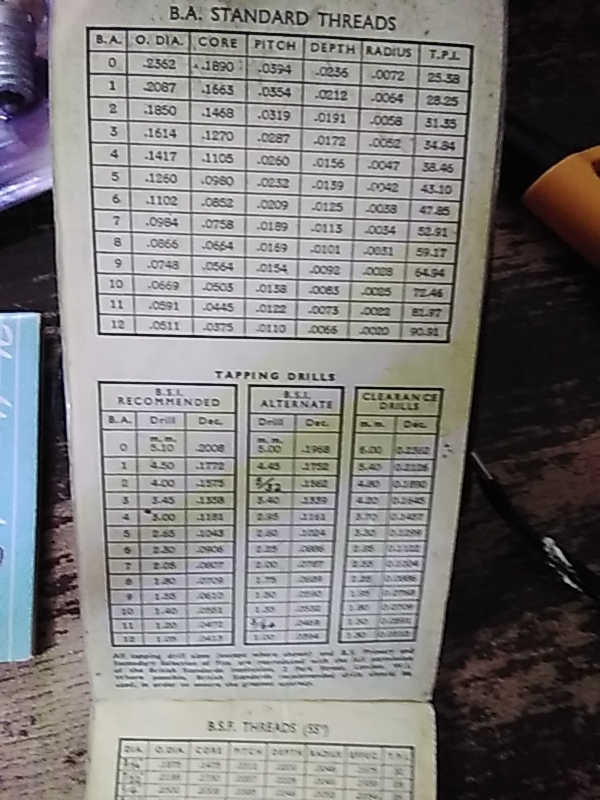

I know BS 93:1951 is obsolescent but BA threads are still in regular use, particularly in Model Engineering.

I've always known the 'Series' to be the most scientific in that the Pitch of each higher 'Number' is 0.9 of the previous rounded to 2 places. That's fine and causes me no problem but I've also understood (Wiki !!) that the OD is 6 times the pitch. That is certainly true as far as 0BA is concerned - 1mm pitch 6mm OD - but it is not so for any others in the series. 10BA is 0.35mm pitch so ought to be 2.09mm OD but is in fact 1.7mm or 4.87555 times the pitch.

I don't have the 'Standard' and haven't been able to find a definitive source which details the precise formula to derive the OD from the pitch.

Can anyone provide such?

I've always known the 'Series' to be the most scientific in that the Pitch of each higher 'Number' is 0.9 of the previous rounded to 2 places. That's fine and causes me no problem but I've also understood (Wiki !!) that the OD is 6 times the pitch. That is certainly true as far as 0BA is concerned - 1mm pitch 6mm OD - but it is not so for any others in the series. 10BA is 0.35mm pitch so ought to be 2.09mm OD but is in fact 1.7mm or 4.87555 times the pitch.

I don't have the 'Standard' and haven't been able to find a definitive source which details the precise formula to derive the OD from the pitch.

Can anyone provide such?