motownmartin

Established Member

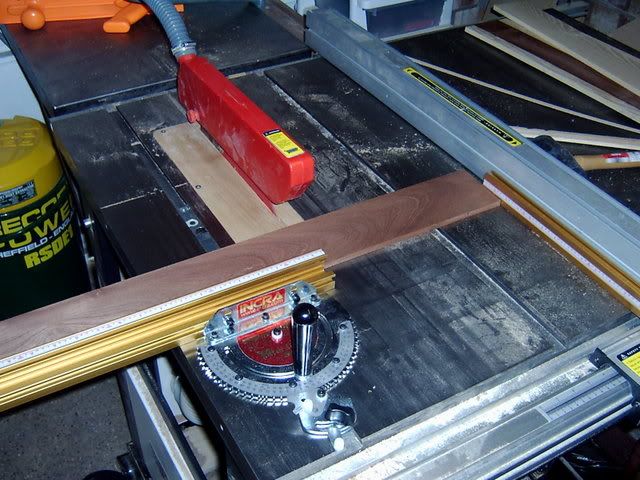

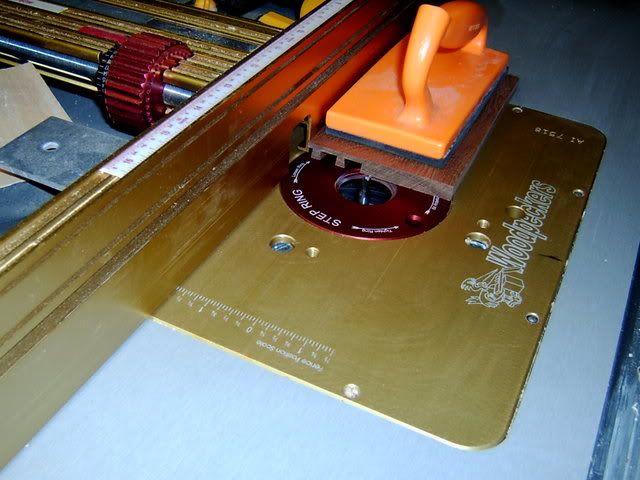

After spending loads of money setting up my workshop, I thought it was about time I attempted to make some snazzy little joints.

After watching the instructional DVD, I thought I would attempt a Double Dovetail with a cornerpost :shock: well, they make it look so easy on the DVD, they don't show you how to do this one so I have to make it up as I go along :?

This is the joint I want to do

Ooooooooerrrrrrrrr

I shall post some more in a bit, just going to sort out some WIP pics

After watching the instructional DVD, I thought I would attempt a Double Dovetail with a cornerpost :shock: well, they make it look so easy on the DVD, they don't show you how to do this one so I have to make it up as I go along :?

This is the joint I want to do

Ooooooooerrrrrrrrr

I shall post some more in a bit, just going to sort out some WIP pics