Richard T":1bzwhumh said:

... and would be very interested to know what your plans are.

I'm guessing that this bar you want to drill and tap is the axle for the drum? ...wooden drum? Turned? Stainless steel teeth? Do tell !

In our previous house in Somerset we had an old cider apple tree and hired a 'pulpmaster' (plastic bucket and spinney cutter thing that fits on an electric drill) and press and experimented with making apple juice and cider. It seemed to work quite well.

Now we've moved to West Sussex and this year looks like we may get a good crop of apples from several trees around the garden. The main croppers are Bramleys which just don't store - they start rotting as soon as you look at them, so we thought rather than wasting them lets try to get some juice, and as an added challenge try to do it all as cheap as possible making use of all that useful stuff that has been kept because it's too good to throw away. So after a bit of research decided to move in the direction of the press and scratter described on the

http://www.ukcider.co.uk/wiki/ website.

Both pieces of kit are still WIP!

The Press.

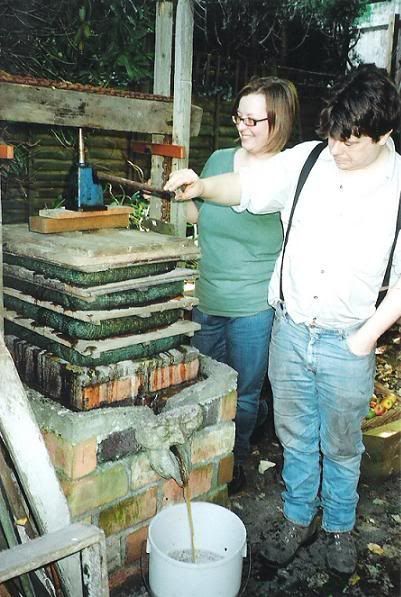

I had some old timber from frames removed when Crittal windows were replaced (you can still see the drip grooves in places). Using an old blade I ripped these into usable sizes and cut off all the naff bits - basically I ended up with roughly 4 x 2 and 4 x 6 bits of timber. I had some offcuts of 10mm stainless studding and also some washers and nuts and used these to make the framework. Also used a few screws for the base. The bit that the apple pulp will be put is is a tray made from an old offcut of laminated worktop with the lipping cut from the same wood above. I've also made a pulp frame to mould the 'cheeses'. We've bought a cheap 2 ton bottle press (from Toolstation) and I've got a bit of plastic conduit to make the juice spout.

Anyway, this is it so far:

The scratter.

I have a 1/3HP electric motor (part on a very old and retired lathe) and also some 3/4 inch bronze bearing blocks, pulley and lock ring that I got off Ebay years ago for a very small amount.

The hopper will be made from some 20ish mm MFC - my whole workshop is lined with this courtesy of my brother-in-law that was give a trailer load (as in articulated lorry trailer) of large rejected sheets (about 8ft x 9ft) that he uses to line some of his business and farm buildings. I have cut these to size and treated the cut edges to make them water/juice resistant.

So to use this i bought a length of 3/4 inch stainless steel rod from Ebay along with some 3/4 stainless washers. I've now drilled this rod and tapped the hole as you can see below. Also you can see the drum I'm making; constructed from an offcut of an oak beam I had to produce a couple of pieces of 6 x 3. I've temporarily fixed them together with pocket screws and turnd it on the lathe to produce the oak cylinder that is to be studded with stainless steel screws. As I've not got the ability/equipment to accurately drill a correct sized central hole to take the cylinder - I've just found a suitable box core bit and have ordered it from Wealden. I'll then route semicircular channels along the axis of the two halves of the cylinder on my router table.

So tomorrow I'll make the hopper and start on the frame and post more bits on here as I go.

Misterfish