JonnyD

Established Member

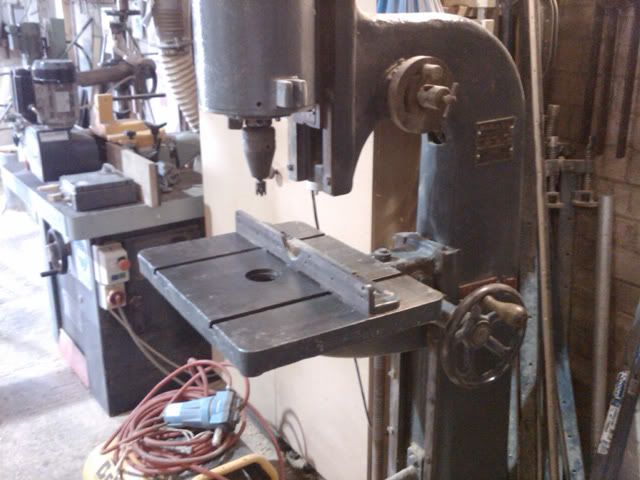

Hi I am wondering if anyone with some metalworking skills/gear would be intersted in a small project. I am after a bush to fit my pillar drill to facilitate the use of jigs for accurate drilling.

The drill is a Wadkin LM

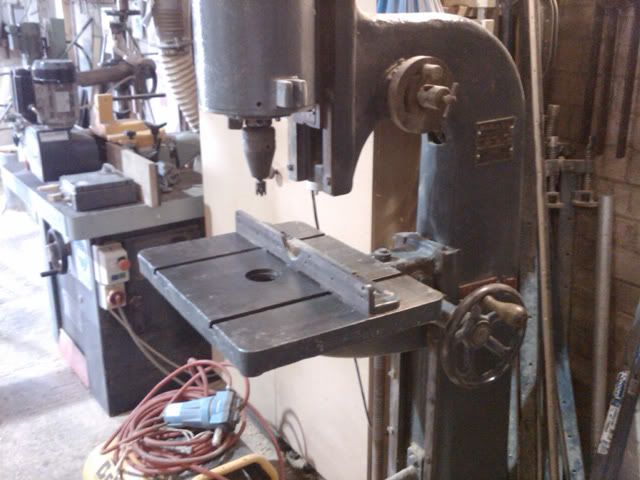

There is a machined hole with a lip where the bush needs to go. The table goes up and down on slideways so the hole is always directly in line with the drill.

I have a set of guidebushes that i dont use that may be able to be converted. The outside is only fractionally bigger than the recess.

The recess is 66mm diameter and 8.5mm deep. The options i can see working are spinning down the guidebush I already have to 66mm. Maching a new 66mm plate to take the internal guide bushes or forgetting the guide bush idea and maching one from scratch.

Any ideas suggestions appreciated.

Jon

The drill is a Wadkin LM

There is a machined hole with a lip where the bush needs to go. The table goes up and down on slideways so the hole is always directly in line with the drill.

I have a set of guidebushes that i dont use that may be able to be converted. The outside is only fractionally bigger than the recess.

The recess is 66mm diameter and 8.5mm deep. The options i can see working are spinning down the guidebush I already have to 66mm. Maching a new 66mm plate to take the internal guide bushes or forgetting the guide bush idea and maching one from scratch.

Any ideas suggestions appreciated.

Jon