You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Antikythera mechanism

- Thread starter Mechanism Man

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 76

Really enjoyed this thread (not a scrollsaw person so only just happened across it).

It's beautiful work and quite inspiring.

Thanks so much for posting.

E.

It's beautiful work and quite inspiring.

Thanks so much for posting.

E.

Mechanism Man

Established Member

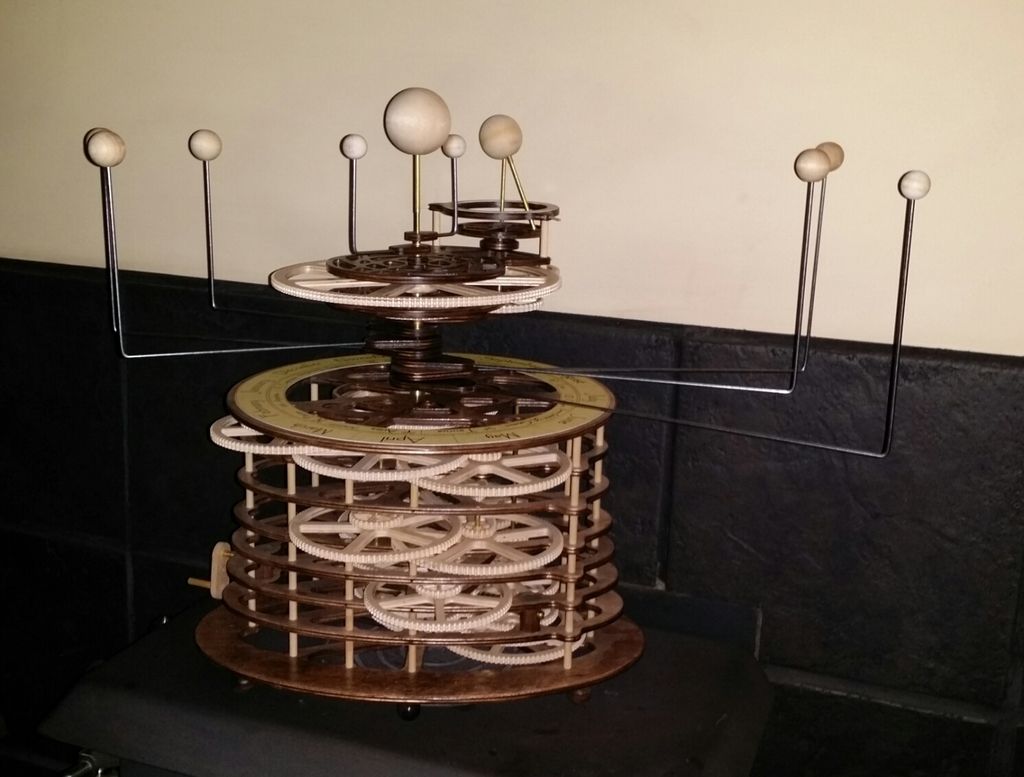

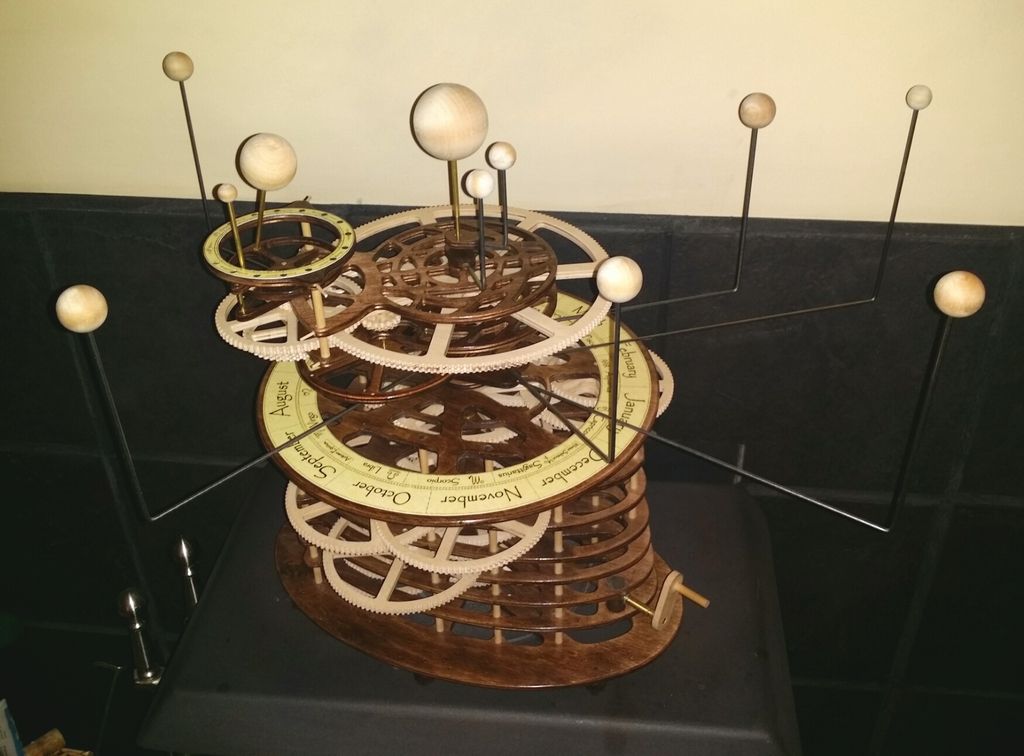

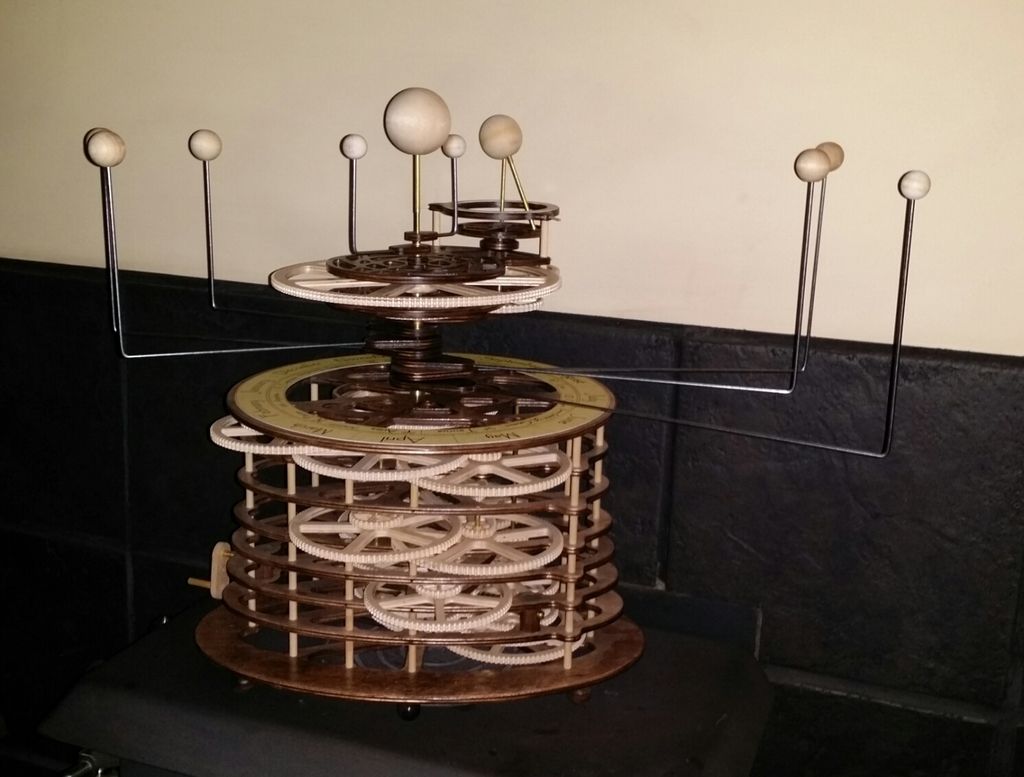

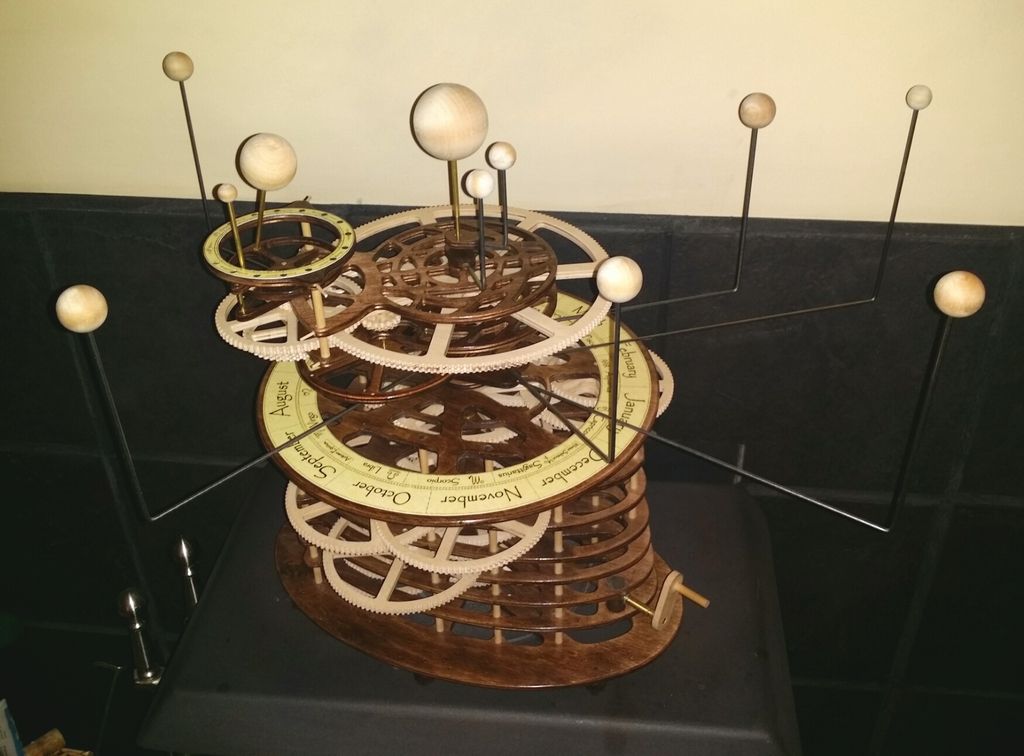

Well after many nights of burning the midnight oil it's finally finished, running, and ready to send. The planets on this are just unfinished wooden balls as that is what the new owner has requested.

All the time taken at the beginning to get the gearing cut well and accurately seems to have paid off as it runs beautifully. This isn't always the case as some I have built have really fought me in the final stages, so I'm relieved that this one just works without having to shout and swear at it...

Anyhow, here are a few photos and a video link of the finished machine (in fact there were a couple of finishing jobs still to do when the photos were taken, but nothing major).

Scroll saws - best tools in the world!

https://youtu.be/qPKRZ4OZuPE

I'll be back with news of the Antikythera build when I've caught my breath and seen my family for a while.

Happy scrolling folks.

All the time taken at the beginning to get the gearing cut well and accurately seems to have paid off as it runs beautifully. This isn't always the case as some I have built have really fought me in the final stages, so I'm relieved that this one just works without having to shout and swear at it...

Anyhow, here are a few photos and a video link of the finished machine (in fact there were a couple of finishing jobs still to do when the photos were taken, but nothing major).

Scroll saws - best tools in the world!

https://youtu.be/qPKRZ4OZuPE

I'll be back with news of the Antikythera build when I've caught my breath and seen my family for a while.

Happy scrolling folks.

lanemaux

In Memorium

I realize that there are probably words , and yet I remain utterly speachless.

martinka

Established Member

I have a metal orrery that came in kit form, so I have some appreciation of the work that went into this, but I am still well and truly gobsmacked. Amazing.

AES

Established Member

Well, I too find myself lost for words - "blimey"!

Congratulations Sir.

AES

Congratulations Sir.

AES

£17.99 (£9.00 / count)

JORGENSEN 300mm Professional Woodworking Clamps 2 Pack, Quick Release Clamps for Wood, F Clamps Set

GreatStarTools

£18.99 (£1.90 / count)

VEVOX® FFP2 Dust Mask - Set of 10 - Valved Face Masks - Respirator - Protection e.g. for Construction, Building Work, Sanding, Woodworking, Fine Dusts, Aersoles or Particles

SLSK Ventures GmbH (UK)

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£400.66

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Qwikfast Trade & DIY Supplies Limited

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£96.66

£102.61

O'SKOOL Mortise and Tenon Jig is Ideal for cabinets, Chairs, and Table Construction Using a Plunge Router

Amazon US

Jamesc

Established Member

=D> =D> =D> =D> =D> =D> =D> =D>

Fantastic work, thanks for sharing

Fantastic work, thanks for sharing

nadnerb

Established Member

I can only say "wow!!"

Regards

Brendan

Regards

Brendan

Mechanism Man

Established Member

Thanks for the kind comments folks - they are very much appreciated. It's not the most social of activities sitting in a shed and cutting out endless gears!

Anyhow, thought that it was high time that I got back to building the original point of the thread.

Well after the stressful two month orrery build it's nice to get back to something with no deadline. So in the the time since sending the orrery off I've managed to get the Antikythera actually running - not to the point where it needs no more work, but well enough to know that it'll actually run as it should, which up to this point had always been a bit debatable.

So below are a couple of photos of the completed gearing, and a couple of YouTube links to it merrily spinning away (with a little help from me).

https://youtu.be/iaAAgGNKhbc

https://youtu.be/1RJDMeesFKE

More soon.

Dave.

Anyhow, thought that it was high time that I got back to building the original point of the thread.

Well after the stressful two month orrery build it's nice to get back to something with no deadline. So in the the time since sending the orrery off I've managed to get the Antikythera actually running - not to the point where it needs no more work, but well enough to know that it'll actually run as it should, which up to this point had always been a bit debatable.

So below are a couple of photos of the completed gearing, and a couple of YouTube links to it merrily spinning away (with a little help from me).

https://youtu.be/iaAAgGNKhbc

https://youtu.be/1RJDMeesFKE

More soon.

Dave.

Jamesc

Established Member

Great to see you back on this, still watching enthralled

bugbear

Established Member

Did you do the pin-and-slot mechanism? I was "fairly impressed" by the Antikythera mechanism

(the original, not your marvellous interpretation) but it's just gear ratios - any amazement

should be reserved for the astronomy, not the technology.

Then I saw the detail of the pin-and-slot non-linear gears...

:shock: :shock: :shock:

:shock: :shock: :shock:

:shock: :shock: :shock:

EDIT: just watched the video - pin-and-slot present and correct!

BugBear

(the original, not your marvellous interpretation) but it's just gear ratios - any amazement

should be reserved for the astronomy, not the technology.

Then I saw the detail of the pin-and-slot non-linear gears...

:shock: :shock: :shock:

:shock: :shock: :shock:

:shock: :shock: :shock:

EDIT: just watched the video - pin-and-slot present and correct!

BugBear

hagdahuk

Member

Impressive!!!! That's a really beautiful work!!

AES

Established Member

Mechanism Man (Dave):

I've now watched your videos. With the greatest possible respect, and in the nicest possible way, you're completely mad mate! The yanks are always shouting "awesome" but your work definitely DOES deserve that accolade.

Thanks for posting.

AES

I've now watched your videos. With the greatest possible respect, and in the nicest possible way, you're completely mad mate! The yanks are always shouting "awesome" but your work definitely DOES deserve that accolade.

Thanks for posting.

AES

bodgerbaz

Established Member

Absolutely amazing. Well done Dave.

martinka

Established Member

I just watched the videos. Stunning work.

For anyone interested there's a 1 hour program all about the antikythera mechanism on youtube.

https://www.youtube.com/watch?v=nZXjUqLMgxM

For anyone interested there's a 1 hour program all about the antikythera mechanism on youtube.

https://www.youtube.com/watch?v=nZXjUqLMgxM

Mechanism Man

Established Member

Afternoon all,

Progress is still painfully slow, but after several months of quietly beavering away here is a link to a film of the basic mechanics of the machine actually running with a handle. If you want to know why the pointers are doing such weird things have a read of the blurb that goes with the film.

https://youtu.be/Ke_wspU5748

Having got it going more or less successfully I very quickly realised that it would need a considerable redesign before I could actually finish it, mainly because the output dials would not fit onto the frames as I'd made them, so it was back to the drawing board (literally!) to come up with a design that would work for the internal gubbins as well as the external wizzy pointy bits. So below is what I've come up with - freshly cut and hastily cobbled together for photographic purposes.

The photos show the front and back of the machine to show the differences between the two. Both front and back will carry their own very different displays hence the different shapes.

I ran into a bit of a hitch having cut them though, my drill press is not big enough to allow me to drill the centre holes in the frames as it's only got a 10.5cm throat depth (about standard for most £100 machines I have discovered). Unfortunately my frames are close to 13cm to the centre of each circle, so I've had to splash out on a shiny new drill press with a much deeper capacity. It's always nice to have an excuse for a shiny new toy, and I have wanted one for a while, but I just wish that I'd worked this out sooner!

The size of the frames is very much a product of the size of the gearing that they're going to contain and the dials that will be fitted onto them, so going smaller wasn't really an option, so I guess I was always going to have to get a bigger machine.

Right, I'm off to start cutting a new batch of gears whilst I wait for the postman.

Until next time ladies and gents.

Progress is still painfully slow, but after several months of quietly beavering away here is a link to a film of the basic mechanics of the machine actually running with a handle. If you want to know why the pointers are doing such weird things have a read of the blurb that goes with the film.

https://youtu.be/Ke_wspU5748

Having got it going more or less successfully I very quickly realised that it would need a considerable redesign before I could actually finish it, mainly because the output dials would not fit onto the frames as I'd made them, so it was back to the drawing board (literally!) to come up with a design that would work for the internal gubbins as well as the external wizzy pointy bits. So below is what I've come up with - freshly cut and hastily cobbled together for photographic purposes.

The photos show the front and back of the machine to show the differences between the two. Both front and back will carry their own very different displays hence the different shapes.

I ran into a bit of a hitch having cut them though, my drill press is not big enough to allow me to drill the centre holes in the frames as it's only got a 10.5cm throat depth (about standard for most £100 machines I have discovered). Unfortunately my frames are close to 13cm to the centre of each circle, so I've had to splash out on a shiny new drill press with a much deeper capacity. It's always nice to have an excuse for a shiny new toy, and I have wanted one for a while, but I just wish that I'd worked this out sooner!

The size of the frames is very much a product of the size of the gearing that they're going to contain and the dials that will be fitted onto them, so going smaller wasn't really an option, so I guess I was always going to have to get a bigger machine.

Right, I'm off to start cutting a new batch of gears whilst I wait for the postman.

Until next time ladies and gents.

AES

Established Member

=D> =D> =D>

Blimey Mechanism Man (Dave?)! That is well above & beyond excellent work. My flabber is well & truly garsted.

Thanks for posting.

{BTW, I won't say a word to Mrs, M.M, 'onest, (hammer) but did you know that with a lot of drill presses it's perfectly possible to swing the drill head/motor assembly off to one side, so allowing drilling of work pieces considerably larger than the throat dimension seems to allow at first sight? Of course, not all of them will do that ).

).

AES

Blimey Mechanism Man (Dave?)! That is well above & beyond excellent work. My flabber is well & truly garsted.

Thanks for posting.

{BTW, I won't say a word to Mrs, M.M, 'onest, (hammer) but did you know that with a lot of drill presses it's perfectly possible to swing the drill head/motor assembly off to one side, so allowing drilling of work pieces considerably larger than the throat dimension seems to allow at first sight? Of course, not all of them will do that

AES

Spindle

Established Member

AES":2531vmaa said:=D> =D> =D>

{BTW, I won't say a word to Mrs, M.M, 'onest, (hammer) but did you know that with a lot of drill presses it's perfectly possible to swing the drill head/motor assembly off to one side, so allowing drilling of work pieces considerably larger than the throat dimension seems to allow at first sight? Of course, not all of them will do that).

AES

Hi

That's interesting - how can you increase the throat when rotating about the column? depth yes but throat?

Regards Mick