BradNaylor

Established Member

- Joined

- 17 Oct 2007

- Messages

- 2,311

- Reaction score

- 2

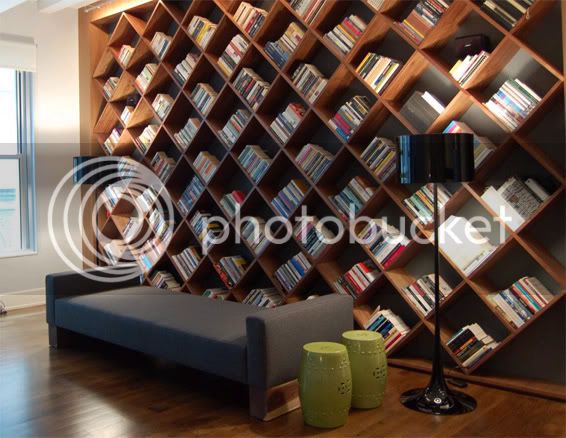

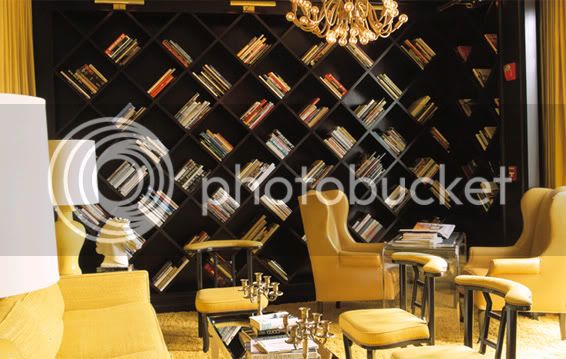

My colleague Phil went to see a bloke yesterday who wants one of these - wall to wall, floor to ceiling.

Our first thought back at the workshop was "Piece of pi$$", and then we looked again. And thought about it.

It's not as straightforward as it looks! Apart from anything else how are we going to pre-fabricate it and assemble it on site? Or do we just put it together like a big lego set?

Suggestions welcome.

Cheers

Brad

Our first thought back at the workshop was "Piece of pi$$", and then we looked again. And thought about it.

It's not as straightforward as it looks! Apart from anything else how are we going to pre-fabricate it and assemble it on site? Or do we just put it together like a big lego set?

Suggestions welcome.

Cheers

Brad