Just a quick update. Not got much done on the project as it was our daughter's birthday yesterday and the weekend has been taken over by visitors, a horse riding party and a round of golf...

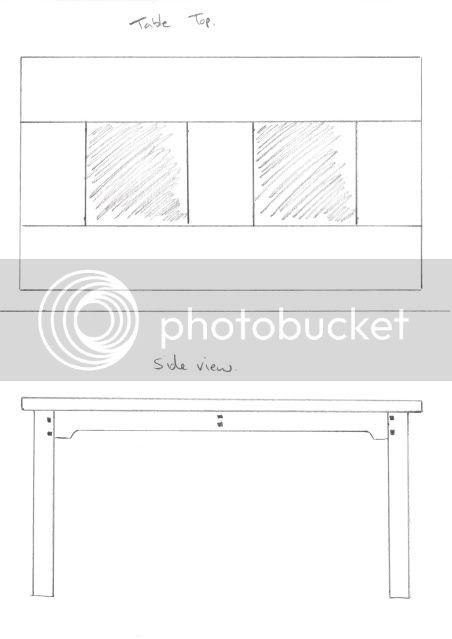

We have thrashed out the final size of the table, and below is a scaled drawing I have done

Overall sizes are 1550mm long, 900 wide and 750mm high. The top is 40mm thick, the legs 75mm square and the rails 110mm, reducing to about 80mm.

The two shaded squares are pieces of granite, which have been chosen to match the granite worktop we have in the kitchen. At some point in the future we may open up the kitchen and dining room into one large kitchen diner, and we thought that this feature would provide some continuity.

The rest of the top is from solid oak, except for the centre piece. I am going to veneer this section, as I don't want to risk putting in solid timber, only for it to be trapped between two pieces of granite.

The frame is very basic, the only detail being the pinned and through mortice and tenon joints, the shape to the rail and a chamfer to the edges of the legs. SWMBO was adamant that she didn't want any shaping on the legs.

Aside from finalising the design, I managed to get all legs planed flat and 2 faces square to each other, ready to go through the thicknesser tomorrow.

I need to pick up another length of 2" stock this week as the top is going to be a little wider than I first anticipated, and all components will need to be jointed from a couple of pieces.

Any comments welcome.

Cheers

Karl