matt":2rpbg441 said:

Think about trying to suck up some dust offyour bench versus blowing it...

I used to work in a factory that made computer hard disks. The company concerned pioneered the 'clean tunnel' approach, as opposed to a clean room.

The assembly was done on conveyors moving slowly past workstations. Parallel to the conveyor, above it were air inlets, from which came very filtered clean air. Right in front of the operators, down to elbow height, were perspex shields, directing the air down, out and away off the edge of the bench and over their knees. They did have to gown up, but only from the waist upwards, and they didn't need face-masks. It was much more comfortable and civilized for the assembly line people than working in a clean room, and the company claimed both cleaner air, and fewer failures too (I believe them). I think it's now become the standard approach (for non-automated processes).

So, to apply that to woodworking, sort of: The particles they had to filter and eliminate were the same size as (or smaller than) the worst woodworking dust. Whilst their filtration cost $loads, the principle of using gravity to advantage still applies: I'd be inclined to introduce fresh air above, and extract from lower down. At worst you hinder dust rising to mouth level, at best it might be a lot more effective than the ceiling mounted filters I've seen in catalogues.

How? In a new build, I'd run a 'ring main' of duct round the wall at ankle level (and bench level where appropriate). I realise this is impractical in an existing shop, but you might drop small ducts down the wall to inlets at the right height.

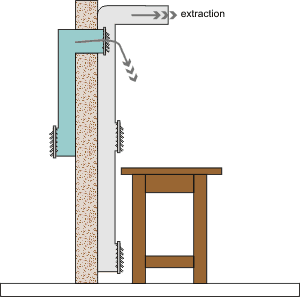

For incoming air, you could just take it from outside. To avoid unwanted draughts, you might adopt the approach used in Victorian chapels: a vertical duct, with the inlet lower down on the outer wall, stops colder air "falling through" the high level opening into the building - ventilation without discomfort. These vents aren't usually very tall - about six feet difference in the ones I've seen. I'd want something like this:

I'd also arrange any baffling so that there was more suck from the lower vent, to encourage the downdraft further.

Your mileage, etc...

[/img]