kasandrich

Established Member

As per title, I fancy having a go at a little box, what I am looking for is confirmation of the order of events.

It will be from seasoned branch stock cherry if that is okay?

My approach would be

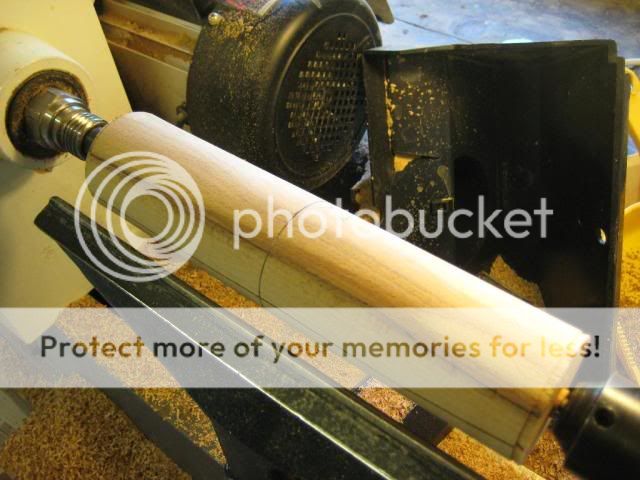

1. Turn between centres, a spigot to suit my chuck on the tailstock end

2. Fit the chuck and mount the spigot turned in 1. in the chuck.

3. Rough it to cylindrical and turn another spigot on the other end.

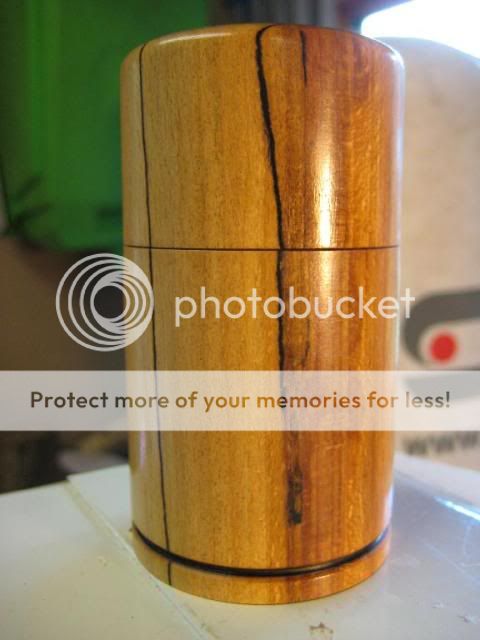

4. Part off the free spigot end leaving enough to form the lid

5. Turn the lip for the lid to sit on

6. Hollow it out

7. Part the box from the scrap in the chuck remove the scrap and mount the lid

8. turn the lip to match the box

9. turn the inside of the lid

10. part the lid off from the spigot

11. Mount the box back in the chuck and fit the lid with a couple of layers of tissue......hopefully it will be a good fit!

12. finish turn the top of the lid

How does that sound as a plan?

Of course sanding and finishing has to be fitted in along the way

It will be from seasoned branch stock cherry if that is okay?

My approach would be

1. Turn between centres, a spigot to suit my chuck on the tailstock end

2. Fit the chuck and mount the spigot turned in 1. in the chuck.

3. Rough it to cylindrical and turn another spigot on the other end.

4. Part off the free spigot end leaving enough to form the lid

5. Turn the lip for the lid to sit on

6. Hollow it out

7. Part the box from the scrap in the chuck remove the scrap and mount the lid

8. turn the lip to match the box

9. turn the inside of the lid

10. part the lid off from the spigot

11. Mount the box back in the chuck and fit the lid with a couple of layers of tissue......hopefully it will be a good fit!

12. finish turn the top of the lid

How does that sound as a plan?

Of course sanding and finishing has to be fitted in along the way