Bluekingfisher

Established Member

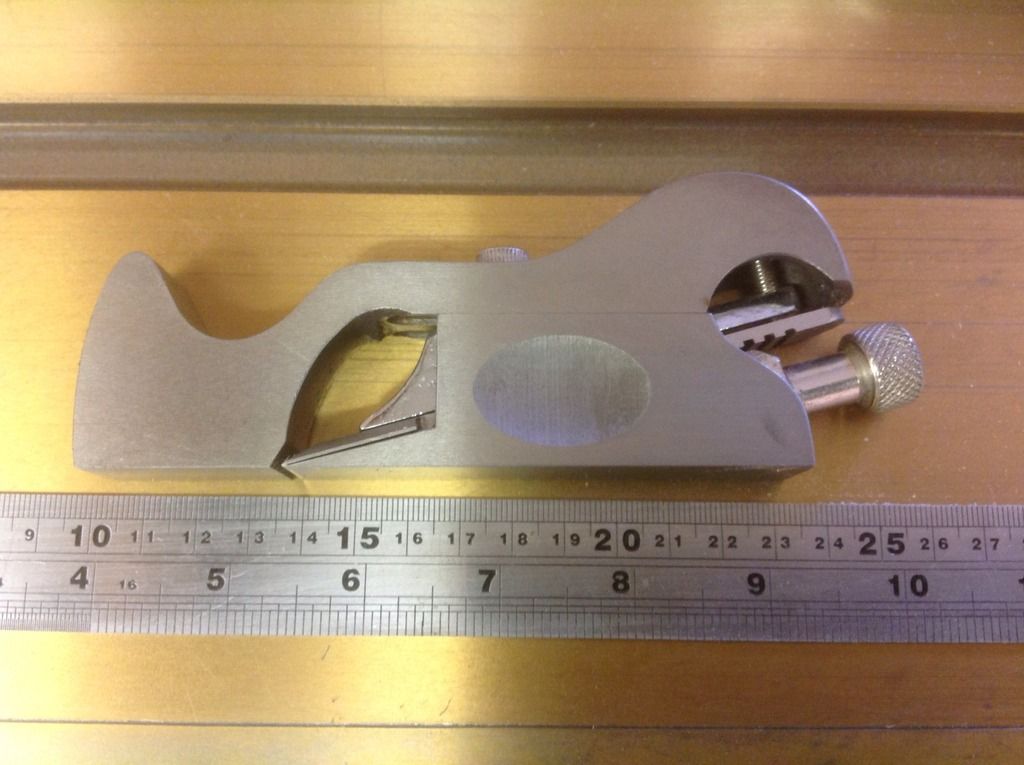

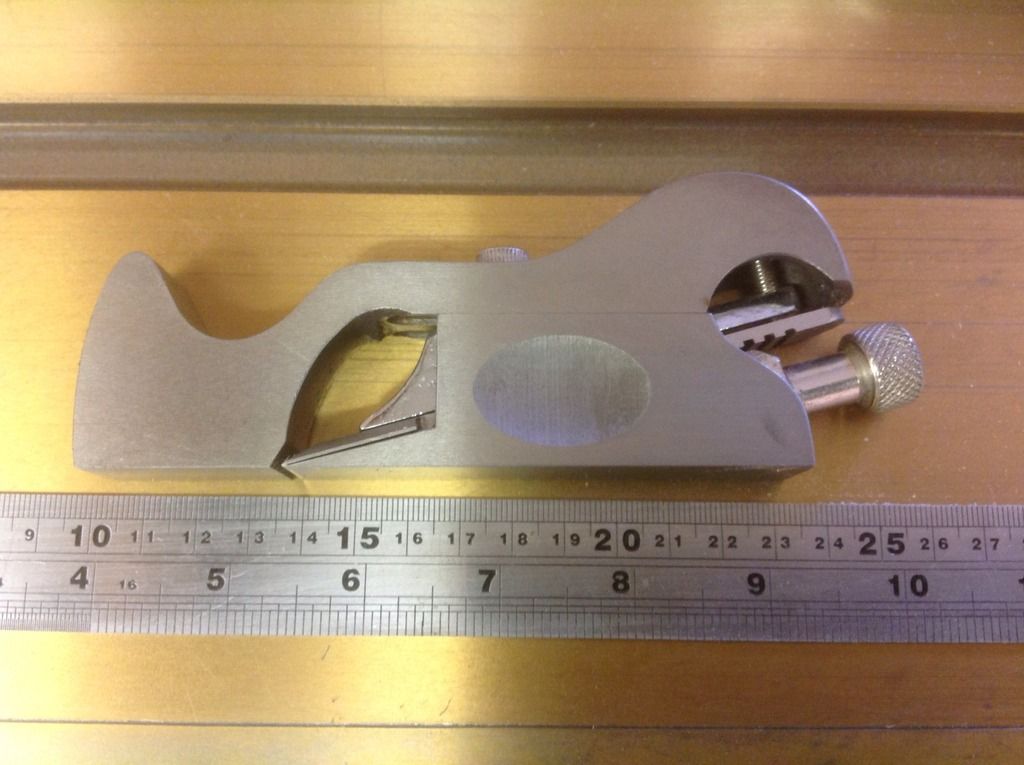

I bought a small shoulder plane from Axminster a couple of years ago while at the store on a shopping trip Photo below). It looked to be well enough made for the money (around £50 if memory serves).

I had no pressing need for it at the time, so after sitting in the tool box I thought I would try it out.

Unfortunately the lever cap snapped on its maiden trial, as can be seen in the photograph. The metal is a cheap & nasty porous "monkey metal" not even suitable for repair.

i suppose my first port of call should be Axminster, however I doubt spares will be avialable for such inexpensive tools. The plane body itself is quite respectable and worthy of salvage, as is the iron.

It looks as though the plane is based on a Stanley #92 ?? If so, do any of you hand palne afficianados know where I could source a spare lever cap from ?

failing that, the part itself does not look too complicated and could possible be fabricated from suitable stock with the aid of a hacksaw and a file. Would brass stock of suitable dimensions be a good option to make the part from? I ask as this would seem to be the simplest to cut and form with limited metal work tools.

Any advice/guidance is appreciated.

Thanks

David

I had no pressing need for it at the time, so after sitting in the tool box I thought I would try it out.

Unfortunately the lever cap snapped on its maiden trial, as can be seen in the photograph. The metal is a cheap & nasty porous "monkey metal" not even suitable for repair.

i suppose my first port of call should be Axminster, however I doubt spares will be avialable for such inexpensive tools. The plane body itself is quite respectable and worthy of salvage, as is the iron.

It looks as though the plane is based on a Stanley #92 ?? If so, do any of you hand palne afficianados know where I could source a spare lever cap from ?

failing that, the part itself does not look too complicated and could possible be fabricated from suitable stock with the aid of a hacksaw and a file. Would brass stock of suitable dimensions be a good option to make the part from? I ask as this would seem to be the simplest to cut and form with limited metal work tools.

Any advice/guidance is appreciated.

Thanks

David